30

2. DISASSEMBLY AND INSPECTION OF ENGINE MAIN PARTS

* Cautions before start

1) Check the cylinder block and cylinder head for wear, leakage and damage.

2) Remove deposit in oil holes of each part with air and check for clogging.

3) Wash each part well to remove dust, contaminated oil, carbon, and other foreign matter.

4) Remove carbon deposited on the piston, cylinder head, valves, etc. carefully not to damage parts. (Great care is necessary

specifically for aluminum alloy parts.)

5) Valves, pistons, connecting rods, metals and other parts which are to be combined as specified should be attached match

marks beforehand to prevent confusion.

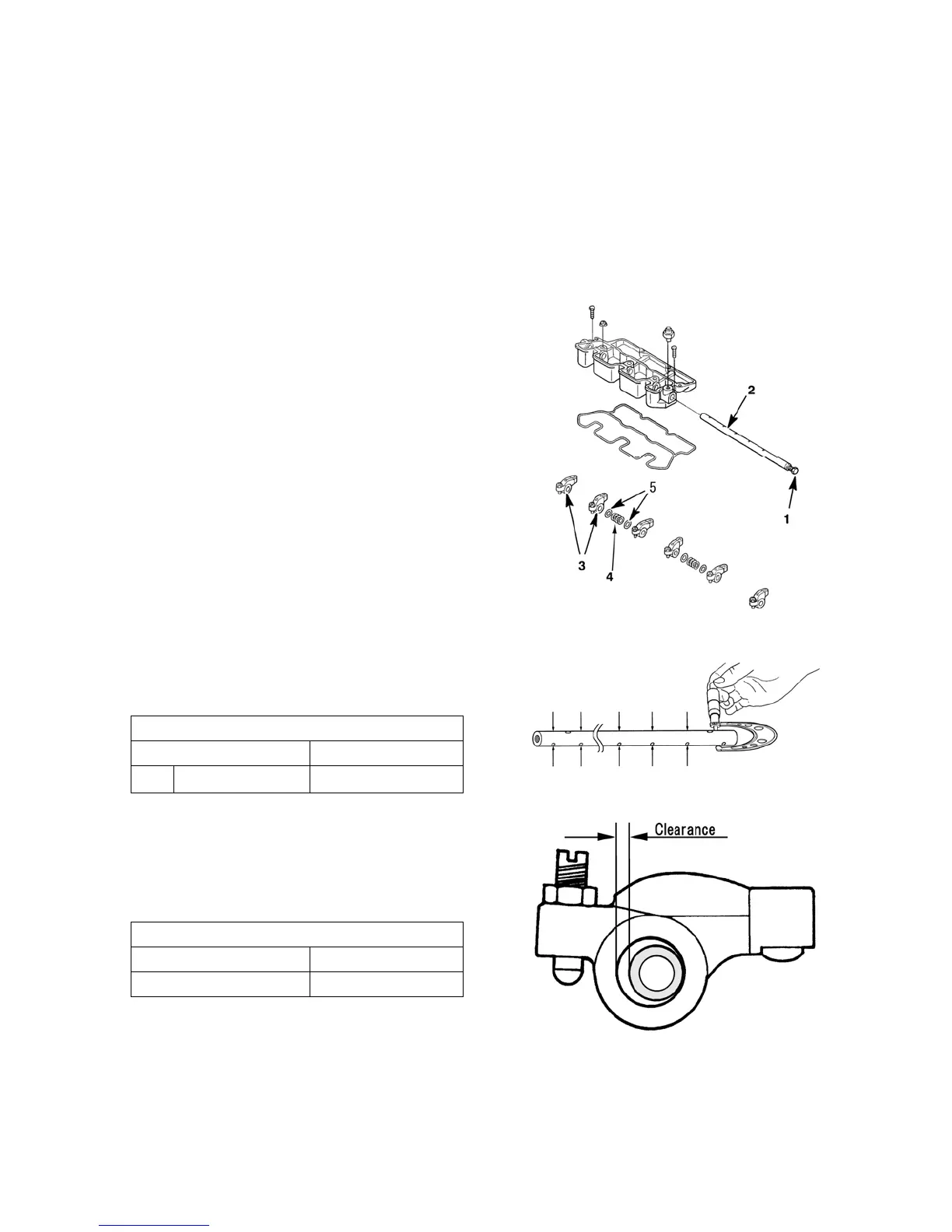

1) Rocker arm ass’y

Disassembly

(1) Thread an 8 mm bolt into the front and of the rocker shaft

and slowly withdraw rocker shaft while at the same time

removing the rocker arms, springs and shims.

1. M8 bolt

2. Rocker arm shaft

3. Rocker arm

4. Spring

5. Shim

Inspection and service

(1) Using a micrometer, check outside diameter of the rocker

arm shaft. If the shaft is worn exceeding service limit,

replace it with new one.

Wear of rocker arm shaft (ø)

Standard assembling value Service limit

N843

14.95-14.97

14.87

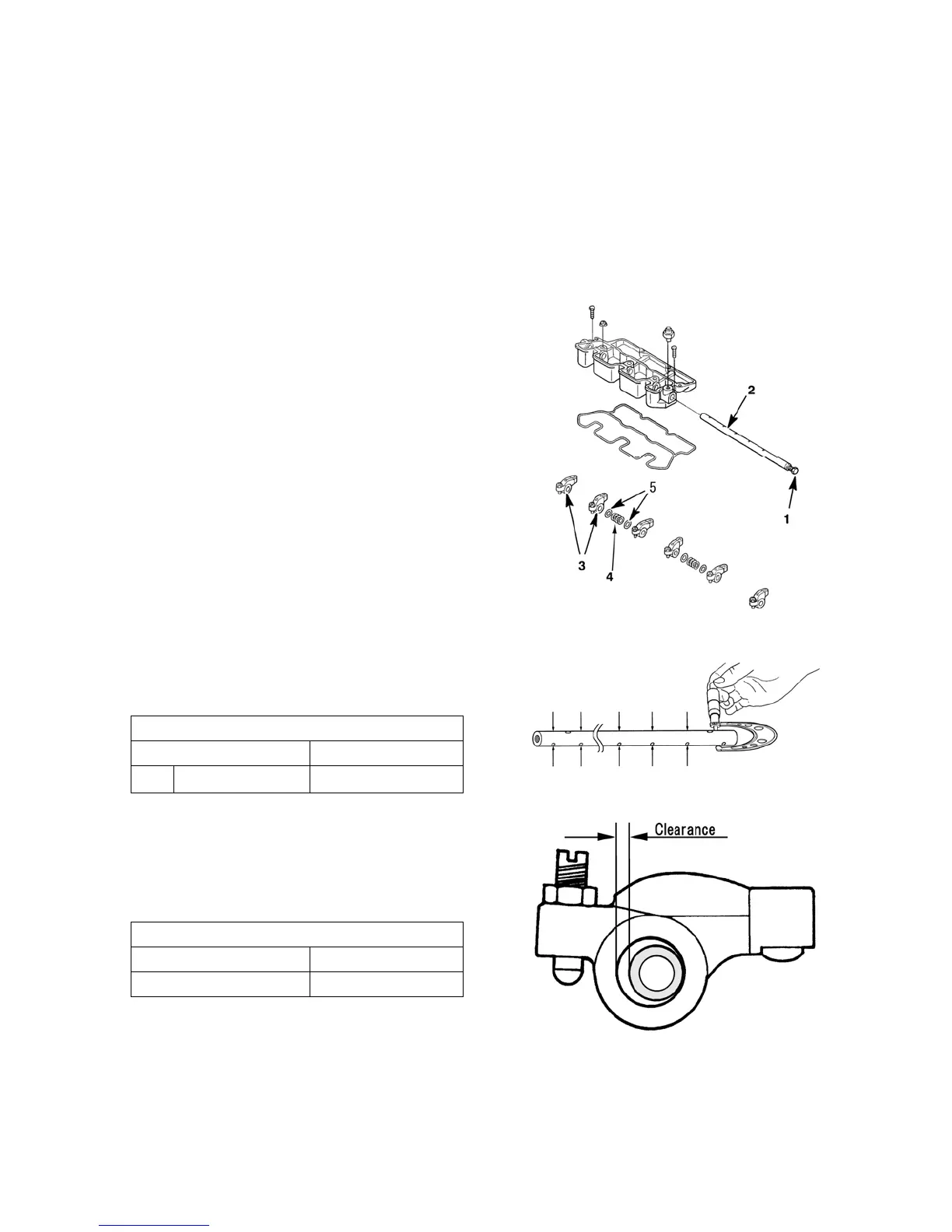

(2) Measure the inside diameter of the rocker arm. Calculate

the clearance between the rocker arm and rocker arm shaft.

If the clearance is excessive, replace the part.

Clearance between rocker arm and rocker arm shaft (mm)

Standard assembling value Service limit

0.032 – 0.068 More than 0.2

(3) Check the valve cap-contact surface for uneven wear and

streaks. Correct curved surface with an oilstone or

grinder correctly if insignificant.

106Y

107Y

108Y

Loading...

Loading...