42

9) Crankshaft

Inspection

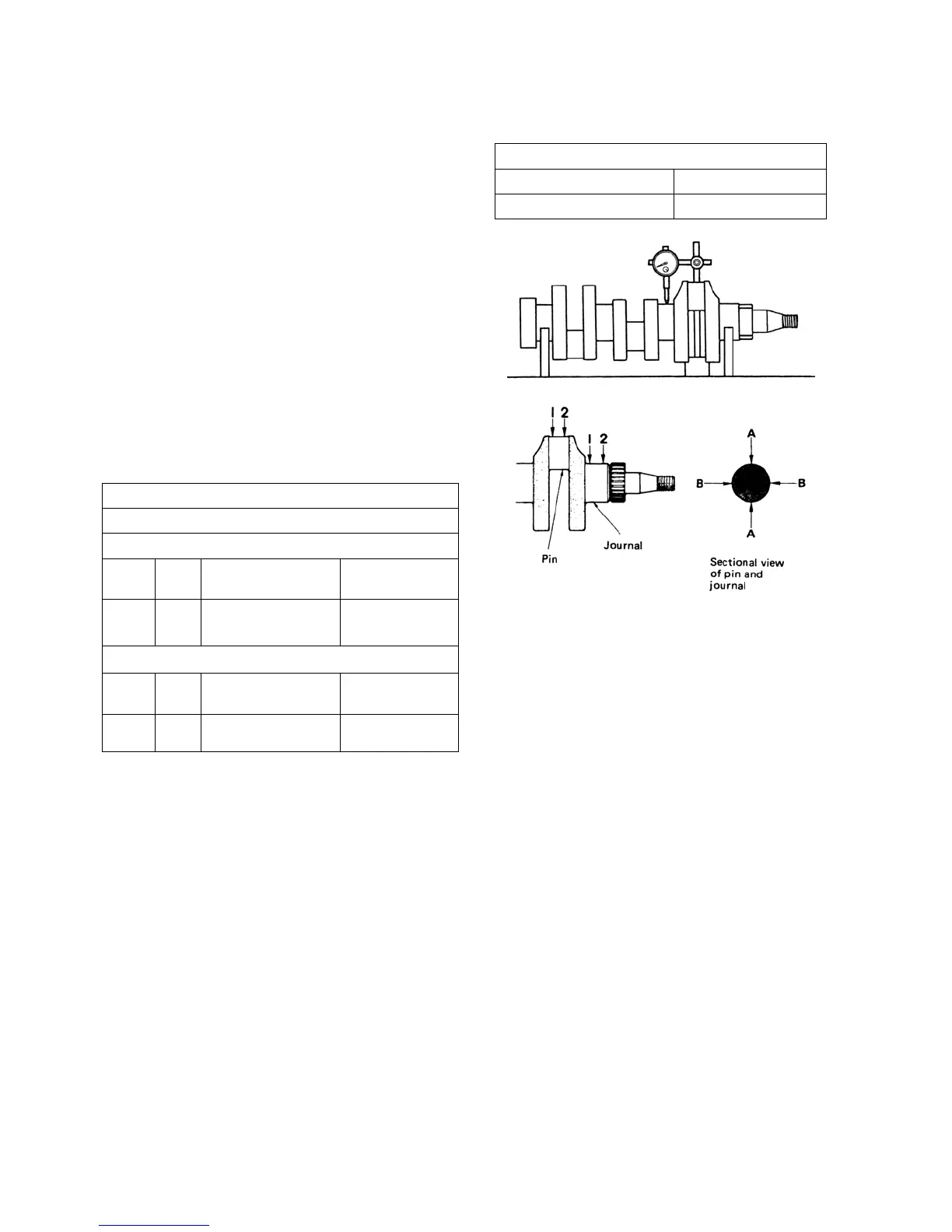

(1) To measure run-out of the crankshaft, support the

crankshaft using a V block as shown in the right figure,

apply a dial gauge to the crankshaft center journal, read

the indication on the dial gauge rotating the shaft one

turn gently. If the service limit is exceeded, correct or

replace.

(2) Check the crankshaft oil seal for damage or wear on the

contact surface and oil hole clogging.

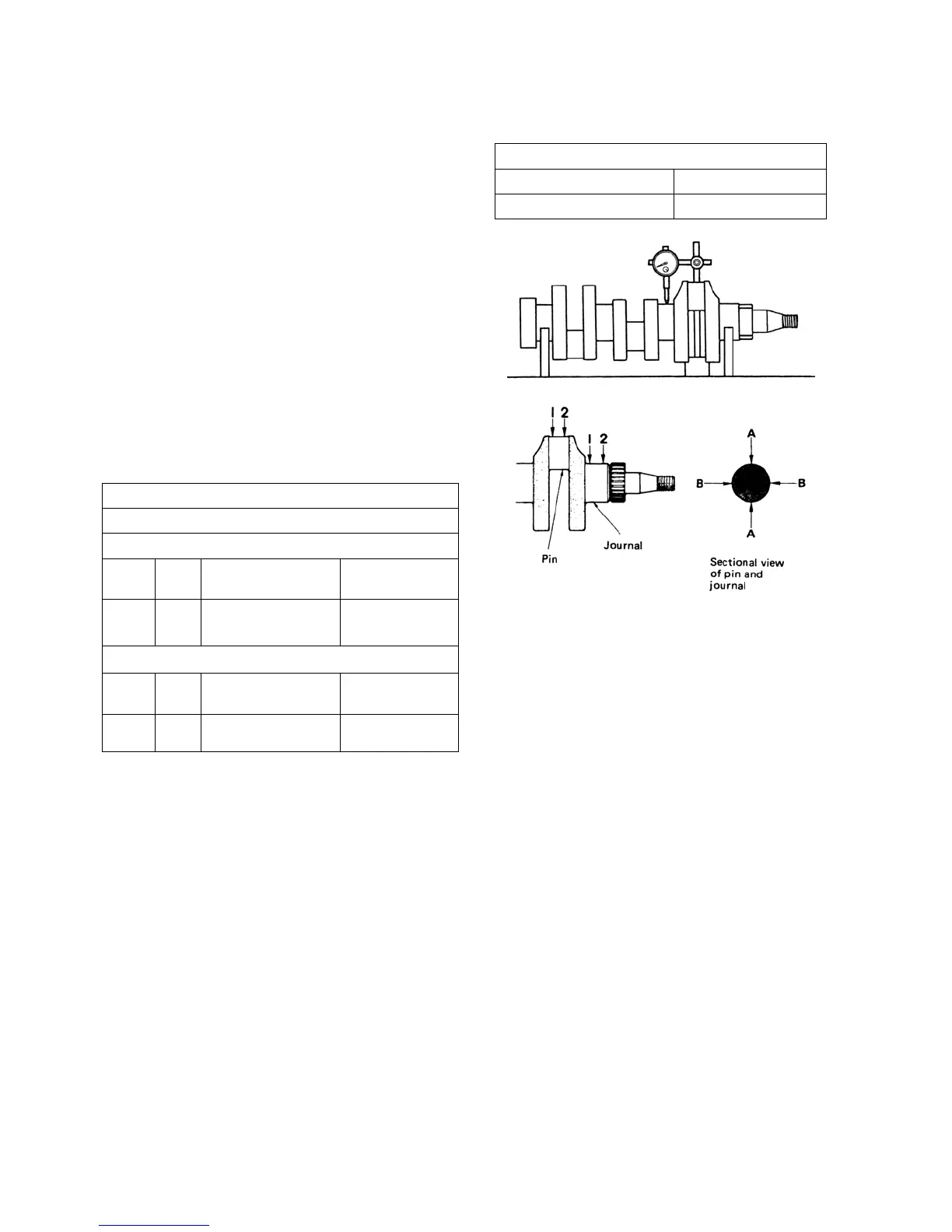

(3) Check the crankshaft journal and pin for damage,

irregular wear (ellipticity, comicalness), and shaft

diameter. If service limit is exceeded replace the bearing

(bush) and/or crankshaft. Measure the dimensions of the

journal and pin in the AA and BB directions at the

position 1 and 2 avoiding the oil holes.

Crankshaft run-out (mm)

Standard assembling value Service limit

Less than 0.03 More than 0.06

133Y

134Y

Irregular wear limit of crankshaft journal and pin (mm)

More than 0.05

Shaft dia. At crankshaft journal

Model

Outside dia. Finishing

dimension

Repair value

N843 STD.

67.957-67.970 67.9

Shaft dia. At crankshaft pin (∅)

Model

Outside dia. Finishing

dimension

Repair value

N843 STD.

51.964-51.975

51.90

Loading...

Loading...