D.3 UL Standards

448 YASKAWA ELECTRIC SIEP C710616 35D YASKAWA AC Drive E1000 Technical Manual

Note: Use crimp insulated terminals or insulated tubing for wiring these connections. Wires should have a continuous maximum

allowable temperature of 75°C 600 V UL approved vinyl sheathed insulation. Ambient temperature should not exceed 40°C.

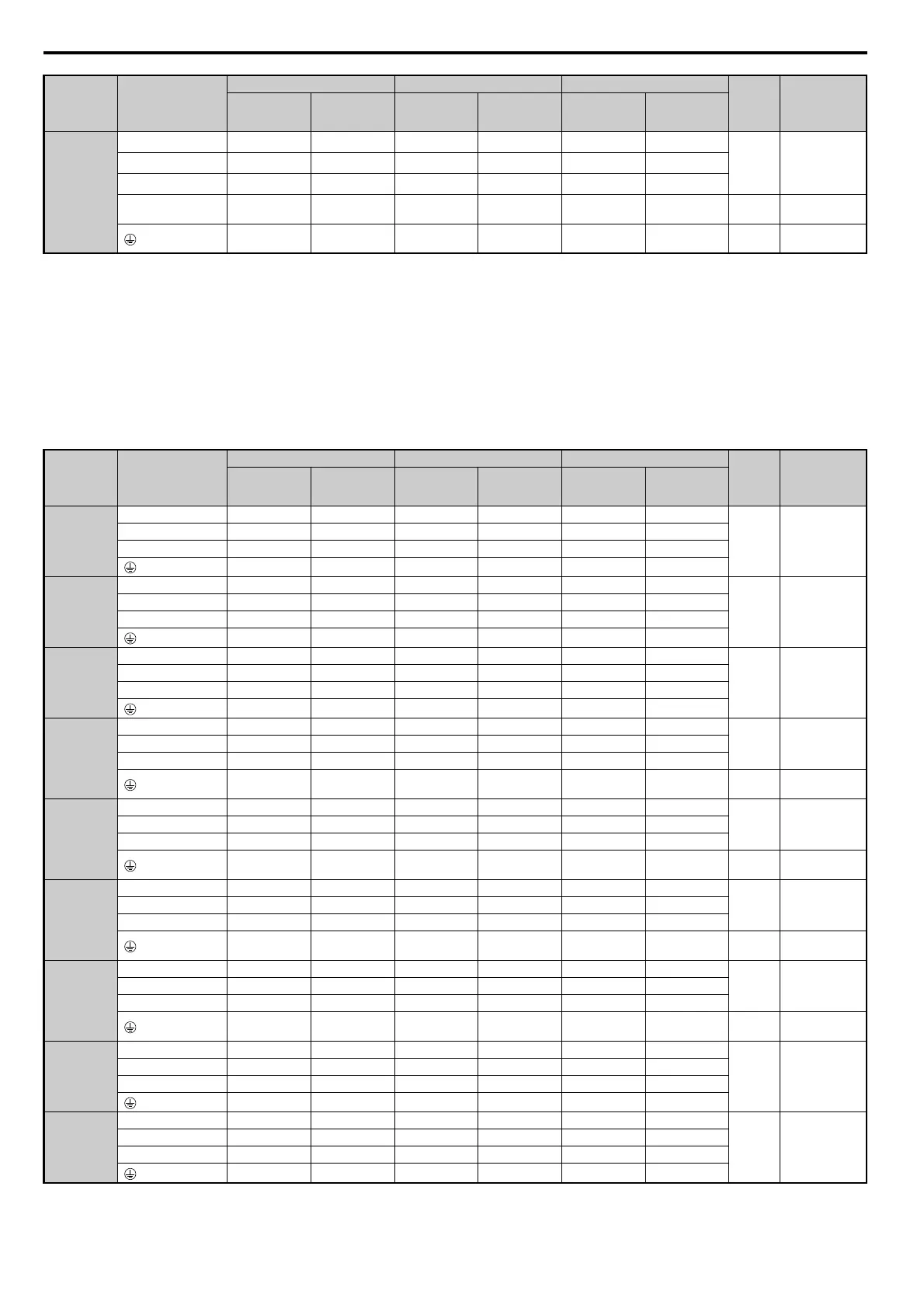

Table D.5 Wire Gauge and Torque Specifications (Three-Phase 400 V Class)

2A0415

<4>

R/L1, S/L2, T/L3 120 × 2P 95 to 300 350 × 2P 250 to 600 125 × 2P 100 to 325

M12

32 to 40

(283 to 354)

U/T1, V/T2, W/T3 300 95 to 300 300 × 2P 300 to 600 125 × 2P 125 to 325

–, +1 – 150 to 300 – 300 to 600 200 × 2P 150 to 325

+3 – 70 to 300 – 3/0 to 600 100 × 2P 80 to 325 M10

18 to 23

(159 to 204)

120 120 to 240 1 1 to 350 60 60 to 200 M12

32 to 40

(283 to 354)

<1> Gauges listed here are for use in Europe and China.

<2> Gauges listed here are for use in the United States.

<3> Gauges listed here are for use in Asia except for China.

<4> Drive models CIMR-E2A0110 to 2A0415 require the use of closed-loop crimp terminals for UL/cUL compliance. Use only the tools

recommended by the terminal manufacturer for crimping.

Model

CIMR-E

Terminal

For Europe and China <1> For U.S.A. <2> For Asia <3>

Screw

Size

Tightening

Torque

Nm (lb.in.)

Recommended

Gauge

mm

2

Applicable

Gauge

mm

2

Recommended

Gauge

AWG, kcmil

Applicable

Gauge

AWG, kcmil

Recommended

Gauge

mm

2

Applicable

Gauge

mm

2

4A0002

4A0004

R/L1, S/L2, T/L3 2.5 2.5 to 6 14 14 to 10 2 2 to 5.5

M4

1.2 to 1.5

(10.6 to 13.3)

U/T1, V/T2, W/T3 2.5 2.5 to 6 14 14 to 10 2 2 to 5.5

–, +1, +2 – 2.5 to 6 – 14 to 10 2 2 to 5.5

2.5 2.5 to 4 12 14 to 12 2 2 to 5.5

4A0005

4A0007

4A0009

R/L1, S/L2, T/L3 2.5 2.5 to 6 14 14 to 10 2 2 to 5.5

M4

1.2 to 1.5

(10.6 to 13.3)

U/T1, V/T2, W/T3 2.5 2.5 to 6 14 14 to 10 2 2 to 5.5

–, +1, +2 – 2.5 to 6 – 14 to 10 2 2 to 5.5

2.5 2.5 to 6 10 14 to 10 3.5 2 to 5.5

4A0011

R/L1, S/L2, T/L3 2.5 2.5 to 6 12 14 to 10 2 2 to 5.5

M4

1.2 to 1.5

(10.6 to 13.3)

U/T1, V/T2, W/T3 2.5 2.5 to 6 14 14 to 10 2 2 to 5.5

–, +1, +2 – 2.5 to 6 – 14 to 10 2 2 to 5.5

2.5 2.5 to 6 10 14 to 10 3.5 2 to 5.5

4A0018

R/L1, S/L2, T/L3 2.5 2.5 to 16 10 12 to 6 3.5 2 to 14

M4

2.1 to 2.3

(18.4 to 20.4)

U/T1, V/T2, W/T3 2.5 2.5 to 16 10 12 to 6 3.5 2 to 14

–, +1, +2 – 4 to 16 – 12 to 6 3.5 2 to 14

2.5 2.5 to 6 10 14 to 10 3.5 2 to 5.5 M5

2 to 2.5

(17.7 to 22.1)

4A0023

R/L1, S/L2, T/L3 4 2.5 to 16 10 10 to 6 5.5 3.5 to 14

M4

2.1 to 2.3

(18.4 to 20.4)

U/T1, V/T2, W/T3 4 2.5 to 16 10 10 to 6 5.5 3.5 to 14

–, +1, +2 – 4 to 16 – 12 to 6 5.5 3.5 to 14

4 4 to 6 10 12 to 10 3.5 3.5 to 5.5 M5

2 to 2.5

(17.7 to 22.1)

4A0031

R/L1, S/L2, T/L3 6 6 to 16 8 8 to 6 14 5.5 to 14

M5

3.6 to 4.0

(31.8 to 35.4)

U/T1, V/T2, W/T3 6 6 to 16 8 10 to 6 8 5.5 to 8

–, +1, +2 – 6 to 16 – 10 to 6 14 5.5 to 14

6 6 to 10 8 10 to 8 5.5 5.5 to 8 M6

5.4 to 6.0

(47.8 to 53.1)

4A0038

R/L1, S/L2, T/L3 10 10 to 16 6 8 to 6 14 14

M5

3.6 to 4.0

(31.8 to 35.4)

U/T1, V/T2, W/T3 6 6 to 16 8 8 to 6 14 8 to 14

–, +1, +2 – 6 to 16 – 6 14 14

10 6 to 16 6 10 to 6 8 5.5 to 14 M6

5.4 to 6.0

(47.8 to 53.1)

4A0044

R/L1, S/L2, T/L3 16 16 to 25 6 6 to 4 14 14 to 22

M6

5.4 to 6.0

(47.8 to 53.1)

U/T1, V/T2, W/T3 16 16 to 25 6 6 to 4 14 14 to 22

–, +1, +2 – 16 to 25 – 6 to 4 14 14 to 22

16 10 to 16 6 8 to 6 8 8 to 14

4A0058

<4>

R/L1, S/L2, T/L3 16 10 to 16 4 6 to 4 14 14

M8

9 to 11

(79.7 to 97.4)

U/T1, V/T2, W/T3 16 10 to 16 4 6 to 4 14 14

–, +1 – 16 to 35 – 6 to 1 22 14 to 38

16 10 to 16 6 8 to 6 8 8 to 14

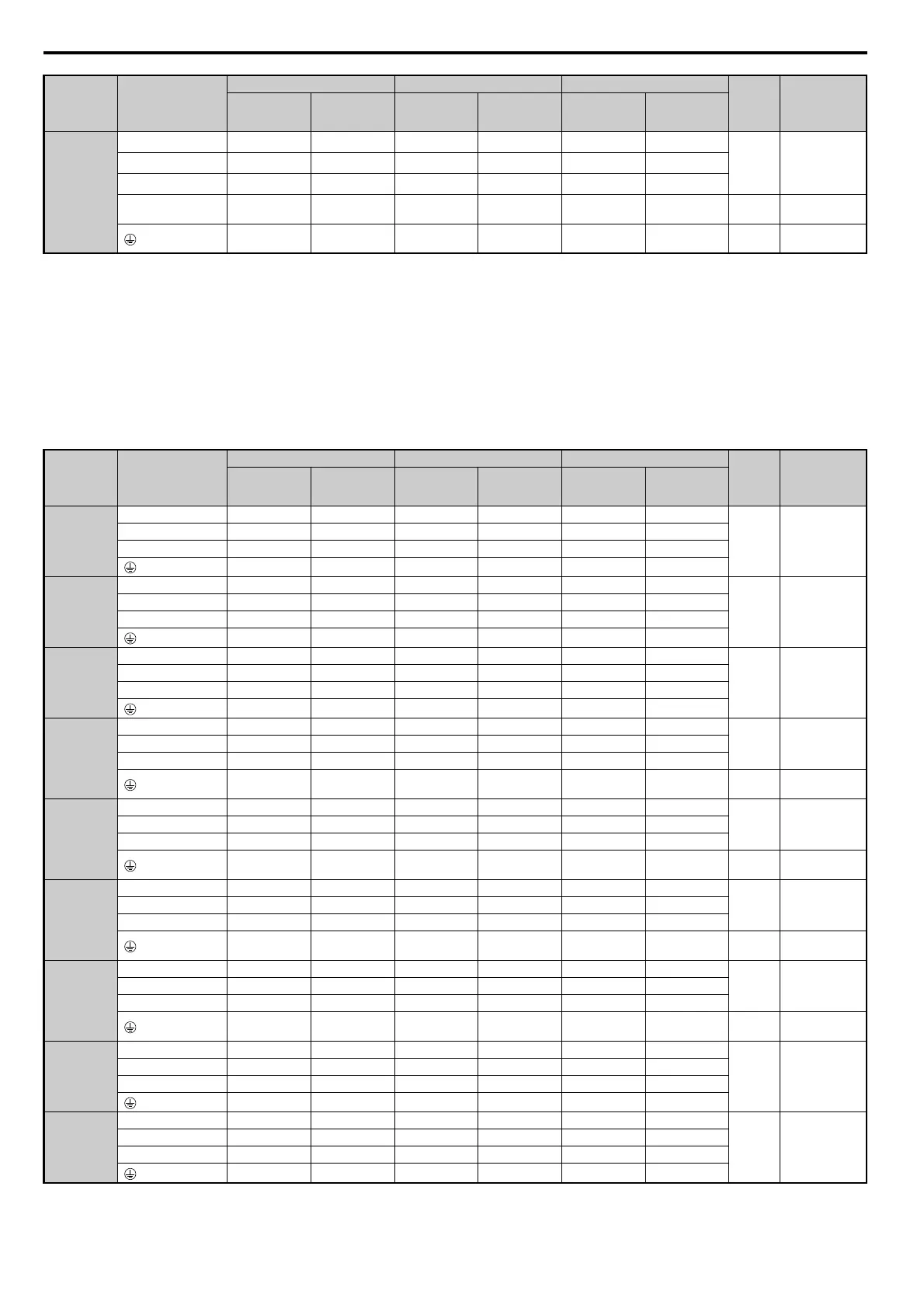

Model

CIMR-E

Terminal

For Europe and China <1> For U.S.A. <2> For Asia <3>

Screw

Size

Tightening

Torque

Nm (lb.in.)

Recommended

Gauge

mm

2

Applicable

Gauge

mm

2

Recommended

Gauge

AWG, kcmil

Applicable

Gauge

AWG, kcmil

Recommended

Gauge

mm

2

Applicable

Gauge

mm

2

SIEP_C710616_35.book 448 ページ 2015年11月30日 月曜日 午後2時2分

Loading...

Loading...