Mounting

Instruction handbook bmaXX 5000

Document No.: 5.09021.19

119

of 346

6

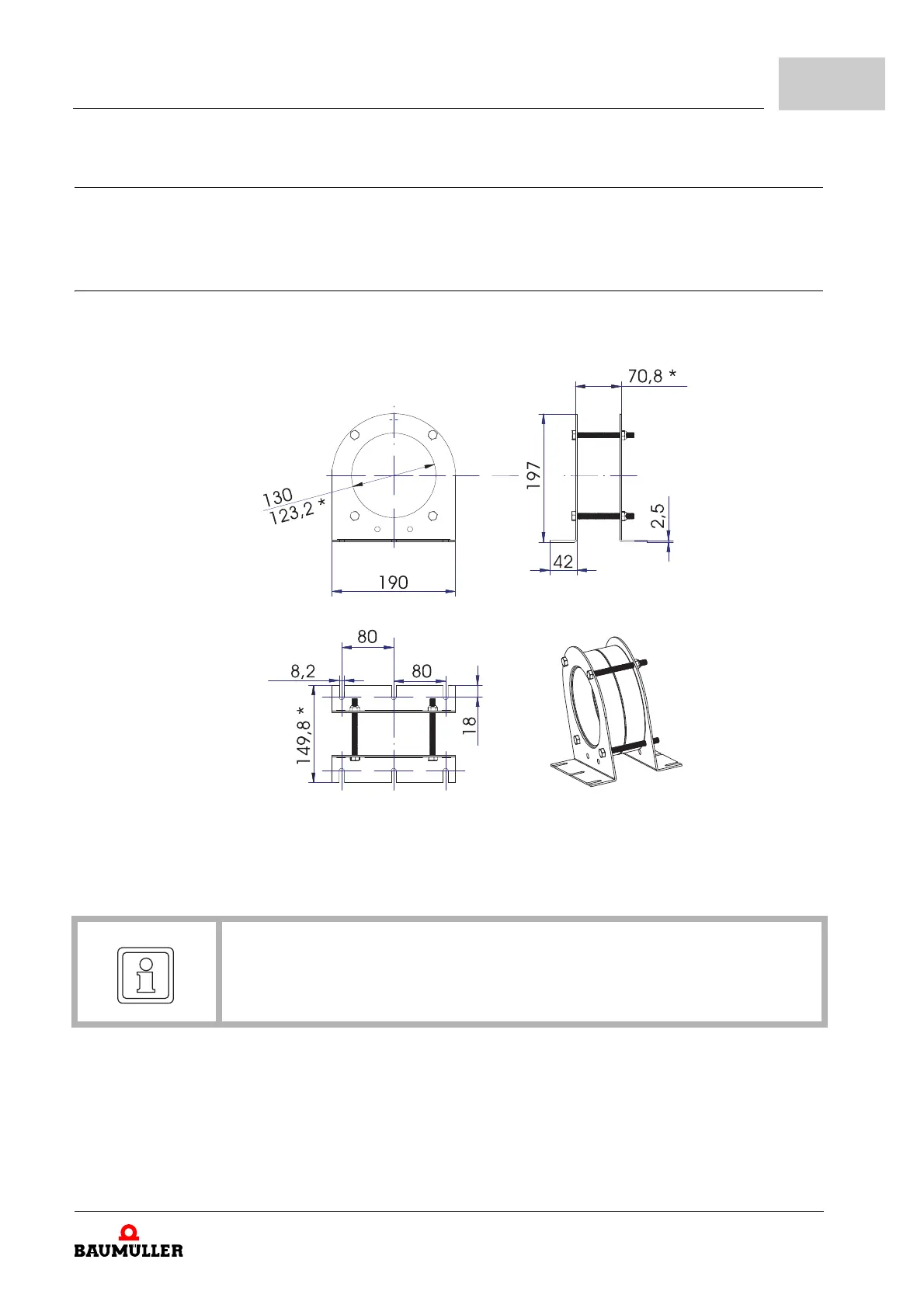

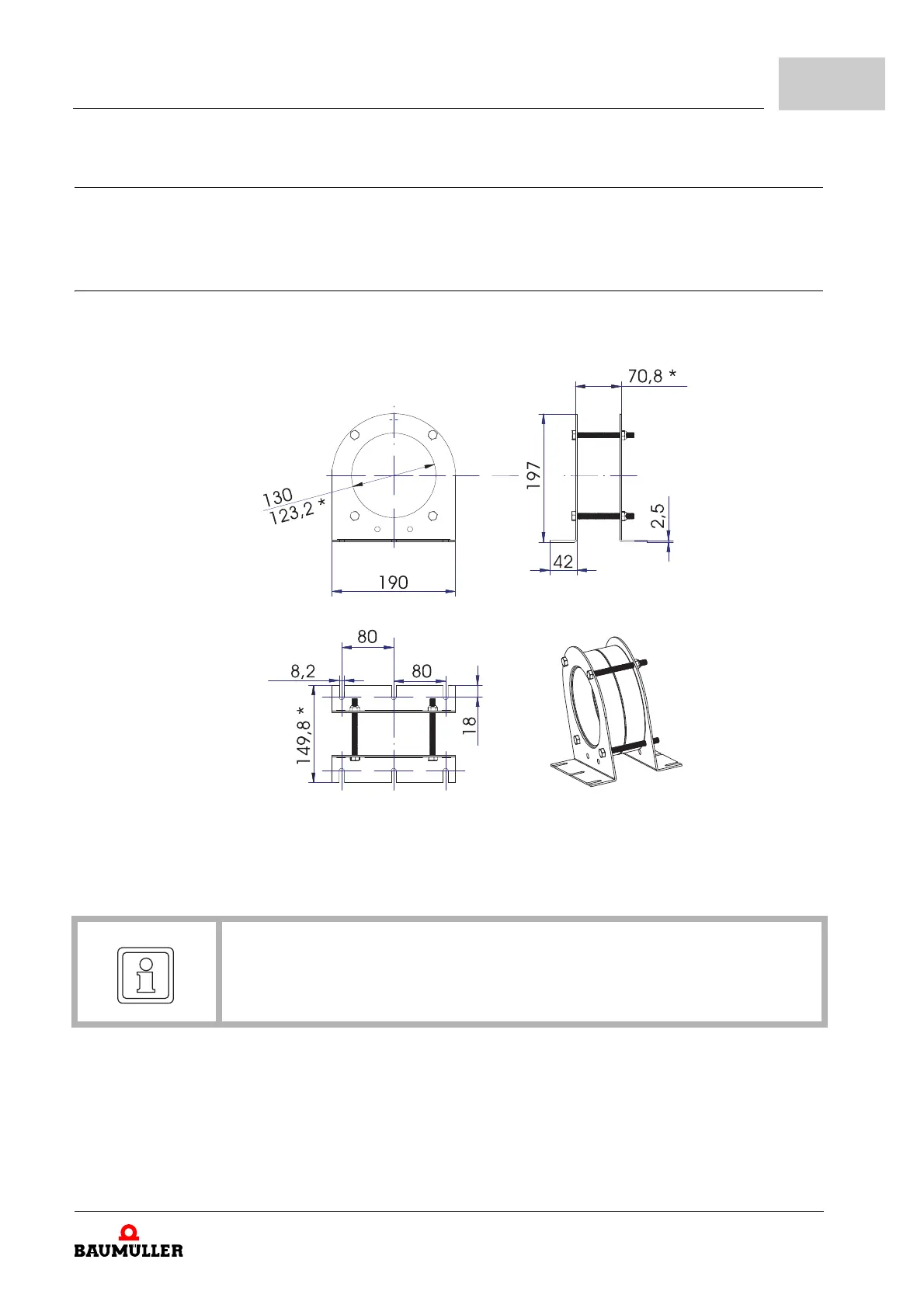

6.2.2 Mechanical data of the mounting plate for cold plate

The cooling version cold plate is a particular efficient cooling alternative. The heat dissi-

pation is done via 2 contact surfaces. The first one is the mounting platform within the con-

trol cabinet or on the machine base, the other is the cold plate on the device’s back. High

requirements e.g. to surface roughness and evenness for this surface are specified, to

ensure an optimal heat flow. Already a slight damage/pollution of the surface can cause

a significant deterioration in heat dissipation to the mounting plate.

For this reason while handle the units protect the sensitive function surface to avoid dam-

age.

6.3 Mounting instructions

There are different mounting procedure.

Each mounting procedure is described in a drawing (see ZFigure 50– on page 120 and

ZFigure 51– on page 121).

The screws and washers required for mounting are listed beneath the respective drawing.

Carry out mounting as follows:

1 Provide suitable transport/lifting equipment as needed.

2 Keep suitable fastening components readily available.

3 For cold plate devices

n check the surface quality of device’s rear panel/mounting plate, see ZMechanical

data of the mounting plate for cold plate– on page 119

4 Mount the device.

5 Subsequently connect the water-cooling unit.

Surface flatness

(across the entire surface)

0.05 mm

Surface roughness Ra 1.2 µm

Material of the plate (recommendation) AlMgSi 0.5

NOTICE!

Property damage due to overheating.

Scratches and burrs can inhibit the heat dissipation of cold plate devices.

Therefore

m When mounting cold plate devices, ensure that the surface quality of the mounting

plate meets the specifications and ensure that the device’s rear panel/mounting

plate does not have any scratches or burrs.

Loading...

Loading...