82.3-0000010 OM

202

5.4.8.5 Operation 64. Maintenance of engine air cleaner

Perform maintenance of the engine air cleaner, when the air filter clogging annunci-

ator, located on the dashboard, lights up, but not less often than every 1000 hours of trac-

tor operation.

To carry out maintenance of the air cleaner, do the following:

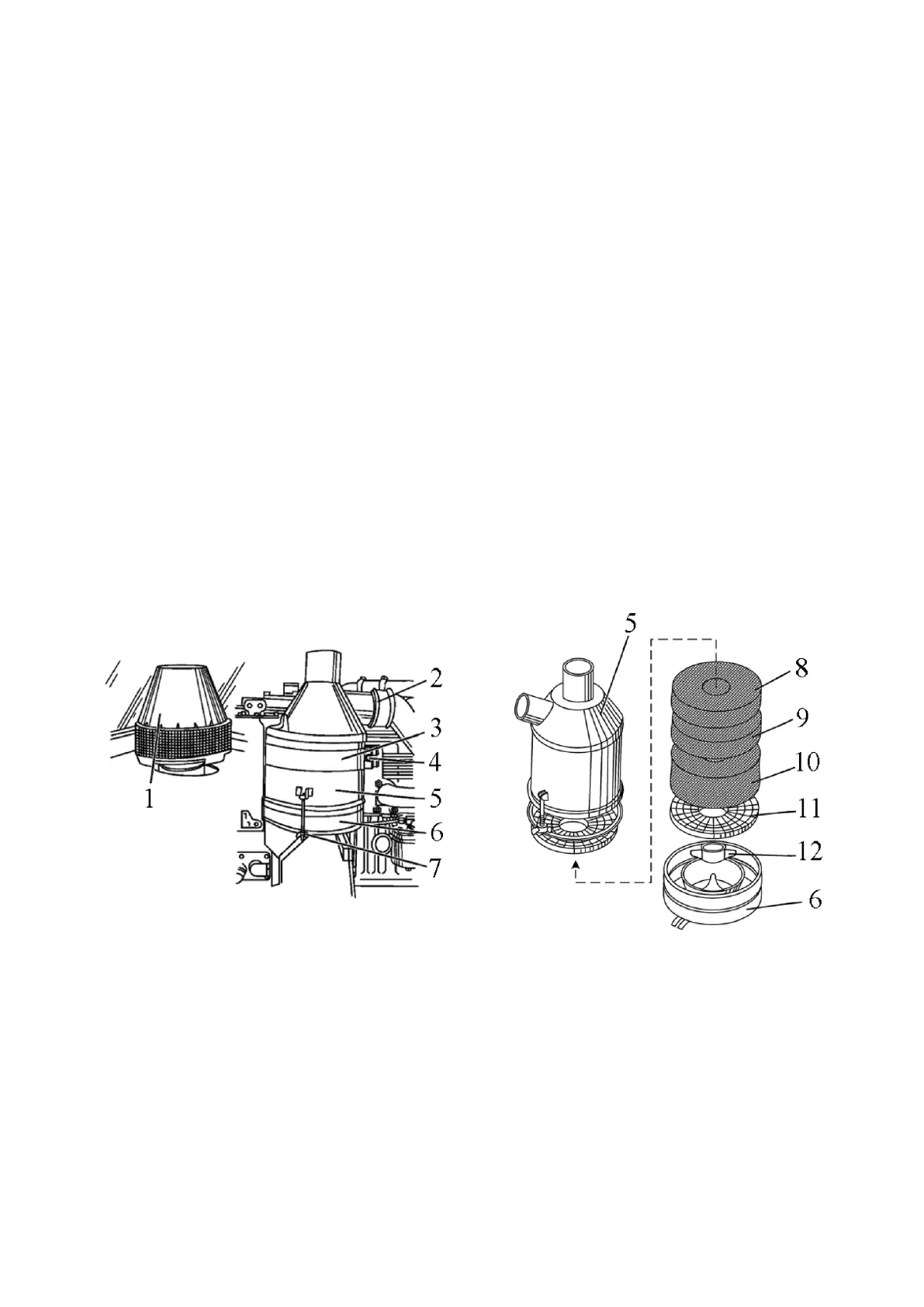

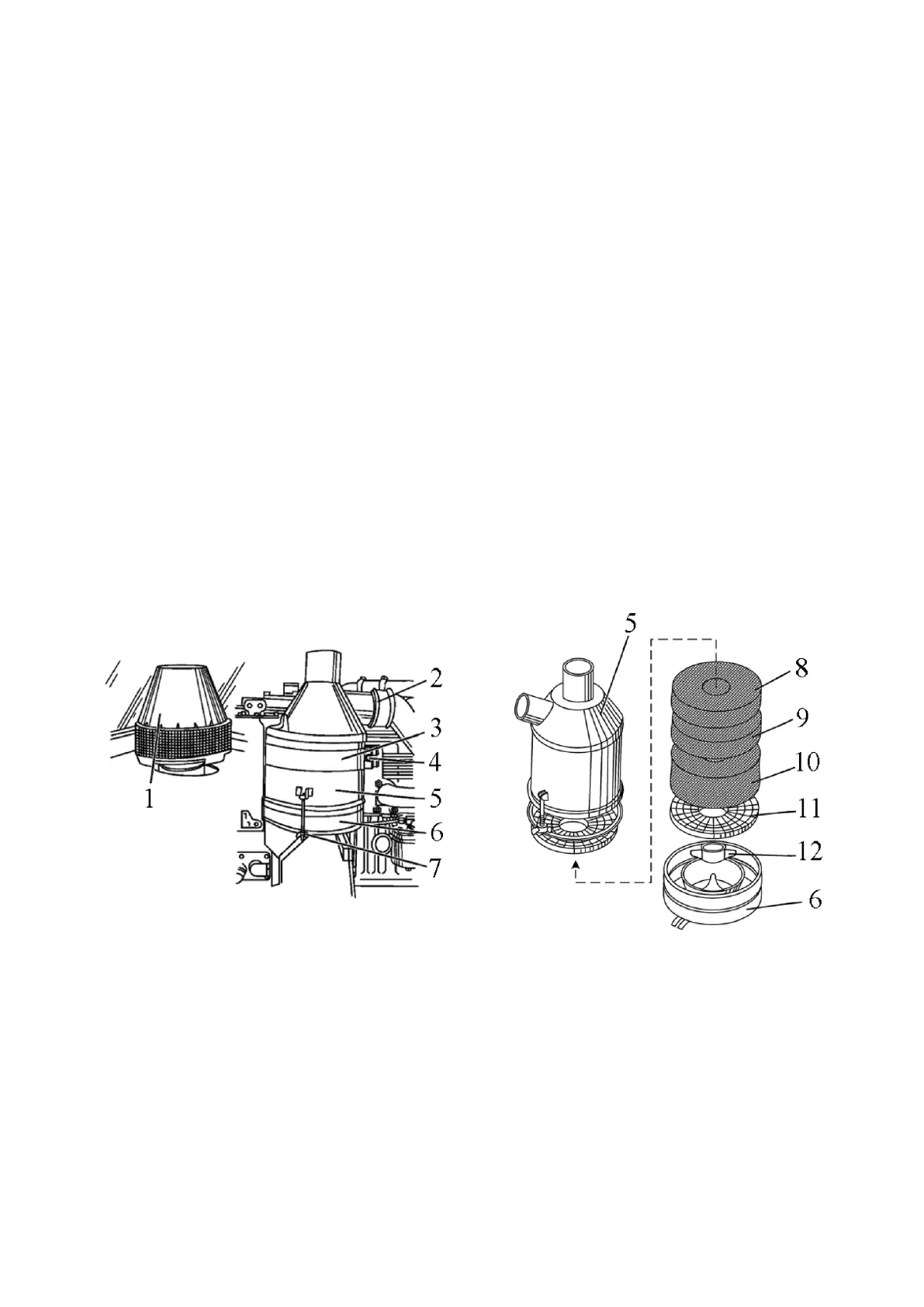

- take off monocyclone 1 (figure 5.4.61) and clean its inner surface.

- loosen clamp 2, undo bolt 4, release clamp 3 and take off air cleaner 5.

- disassemble air cleaner 5 by loosening two nuts 7 and removing sump 6;

- then take out three filter cartridges 8, 9 and 10, rinse them in diesel fuel and purge with

compressed air. The air pressure shall be between 0.2 to 0.3 MPa;

- drain oil from sump 6 into a special container;

- clean and rinse sump 6, air cleaner body 5 and the central pipe in diesel fuel. Let

the fuel flow down, and purge the parts with compressed air.

- assemble the air cleaner after the rinsing by mounting filter cartridges 8, 9 and 10

in the following order: first cartridge 8 made of thread with the smallest diameter 0.22 mm

(weight 220 g); then filter cartridge 9 made of thread with medium diameter 0.24 mm

(weight 140 g), and finally filter cartridge 10 made of thread with the largest diameter 0.4

mm (weight 100 g), the mount cage 11 and stopper 12;

- fill sump 6 with oil up to the level of the annular groove and mount it into the air

cleaner;

- install the air cleaner on the engine;

- check all connections of the air cleaner and intake air line for air-tightness, detect

and eliminate leakiness of air duct according to clause 5.4.4.7 “Operation 37. Check of air-

tightness of all connections of air cleaner and intake duct”.

1 – monocyclone; 2, 3 – clamp, 4 – bolt; 5 – air cleaner; 6 – sump; 7 – nut; 8, 9, 10 – fil-

ter cartridges; 11 – cage; 12 – stopper.

Figure 5.4.61 – Maintenance of engine air cleaner

ATTENTION: UNTIMELY MAINTENANCE OF AIR CLEANER DECREASES THE

QUALITY OF AIR CLEANING AND CAUSES INGRESS OF DUST INTO THE ENGINE,

WHICH LEADS TO INCREASED WEAR OF CYLINDER-PISTON GROUP AND ENGINE

BREAKDOWN!

Loading...

Loading...