1 689 989 000 2013-05-02| Robert Bosch GmbH

40 | EPS 200 | Operationen

5.4.2 DHK/UI test sequence

Warning - Risk of burns!

The hot surface of the hose lines and compo-

nents can result in severe burns to the hands.

¶ Allow hose lines and components to cool

down before removing them.

¶ Wear protective gloves.

! Do not test any damaged and/or heavily corroded

components.

X20

4

2

459822-91

1

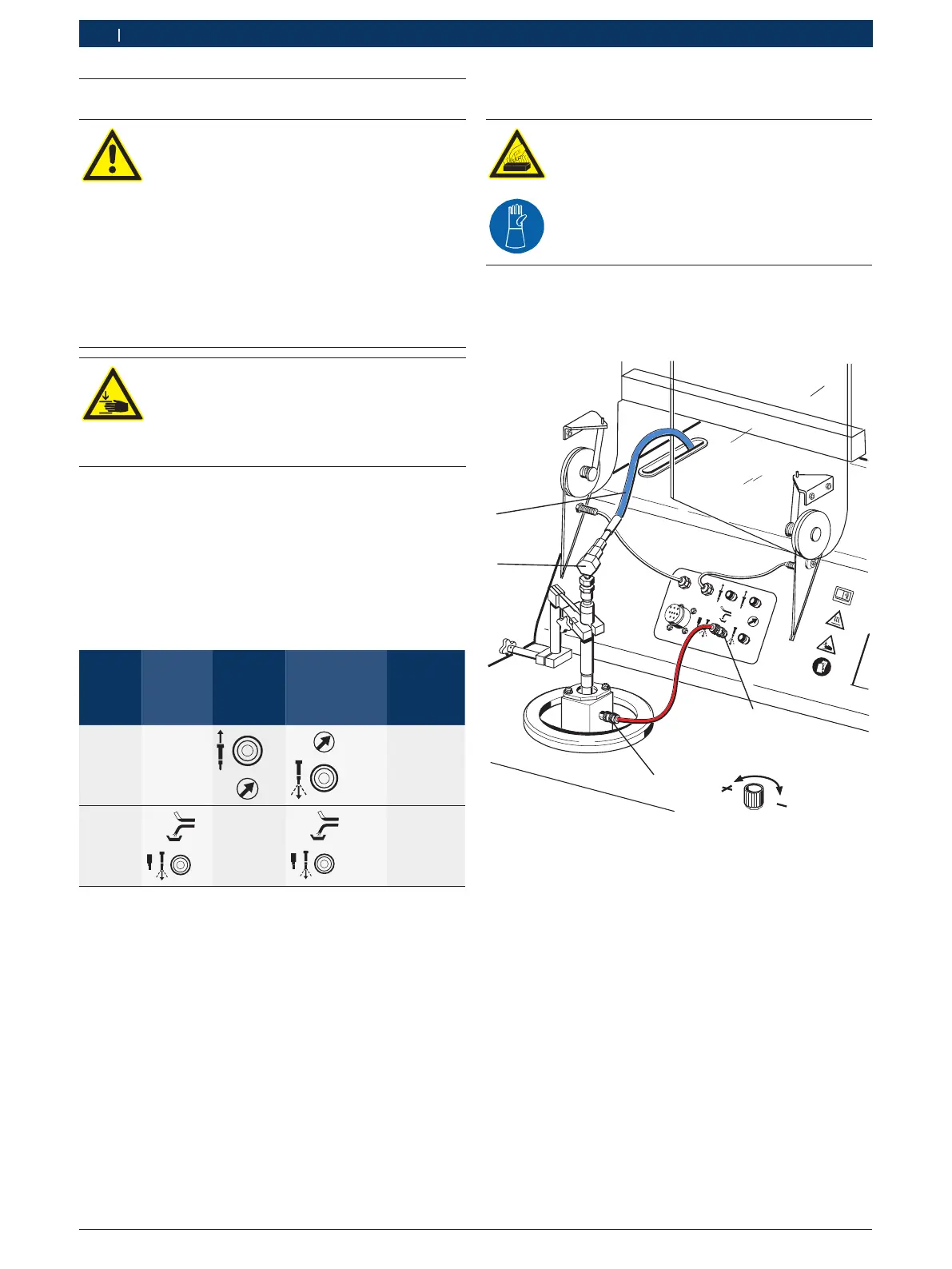

Fig. 20: DHK connection

1 Flushing connection/test connection DHK/UI

2 Injection chamber quick-release coupling

3 Connection adapter

4 High pressure connecting line

i The requirements to be considered for testing and

adjusting DHK/UI components are set out in the

test instructions for DHK/UI in ESI[tronic]. These

test instructions are not supplied. The ESI[tronic]

software cannot be installed on the EPS 200.

5.4 Operation

Warning - Risk of injury!

If the hydraulic connections for the testing

equipment and the components are not

set up properly, test oil can escape at high

pressure during the test or components of

the testing equipment can burst.

This can cause injury or damage to property

¶ Before turning on, check that all hose

lines on the EPS 200 and on the compo-

nent are connected properly.

¶ Replace any leaky or defective hose lines.

Warning – Hand injury!

If the protective cover is allowed to fall,

fingers can be crushed or injured.

¶ Always close the protective cover using

the handle.

! Only fit a cleaned CRI/CRIN and DHK/UI for testing.

Clean injectors around the injection nozzle and the

nozzle clamping. Do not fit a damaged or heavily cor-

roded CRI/CRIN and DHK/UI for testing.

5.4.1 Symbols and connection overview for CRI/CRIN

and DHK/UI tests

Com-

ponent

Flushing

connect-

ion

Test

con-

nection

(return)

Test

connection

(injection)

Electrical

connecting

cable X20

CRI/

CRIN

Not

required

Yes

DHK/UI Not

required

Not re-

quired

Loading...

Loading...