Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

Menu 4

Unidrive SP Advanced User Guide 99

Issue Number: 7 www.controltechniques.com

The thermal protection system can be used in regen mode to protect the input inductors. The rated current (Pr 5.07) should be set to the rated current

for the inductors. The thermal model temperature accumulator is reset to zero at power-up and accumulates the temperature of the motor whilst the

drive remains powered-up. Each time Pr 11.45 is changed to select a new motor, or the rated current defined by Pr 5.07 or Pr 21.07 (depending on

the motor selected) is altered, the accumulator is reset to zero.

The drive reactive current is shown in this parameter for all modes.

The current limit applied at any time depends on whether the drive is motoring or regenerating and also on the level of the symmetrical current limit.

Pr 4.18 gives the limit level that applies at any instant.

See Pr 4.16 on page 97.

Open-loop, Closed-loop vector, Servo

This parameter displays the actual torque producing current (Pr 4.02) as a percentage of rated active current. Positive values indicate motoring and

negative values indicate regenerating.

Regen

This parameter displays the active current (Pr 4.02) as a percentage of the rated current (Pr 5.07 or Pr 21.07). Positive values indicate power flow

from the supply and negative values indicate power into the supply

If this parameter is set to one, the drive calculates a torque reference from the motor and load inertia (Pr 3.18) and the rate of change of speed

reference. The torque reference is added to the speed controller output to provide inertia compensation. This can be used in speed or torque control

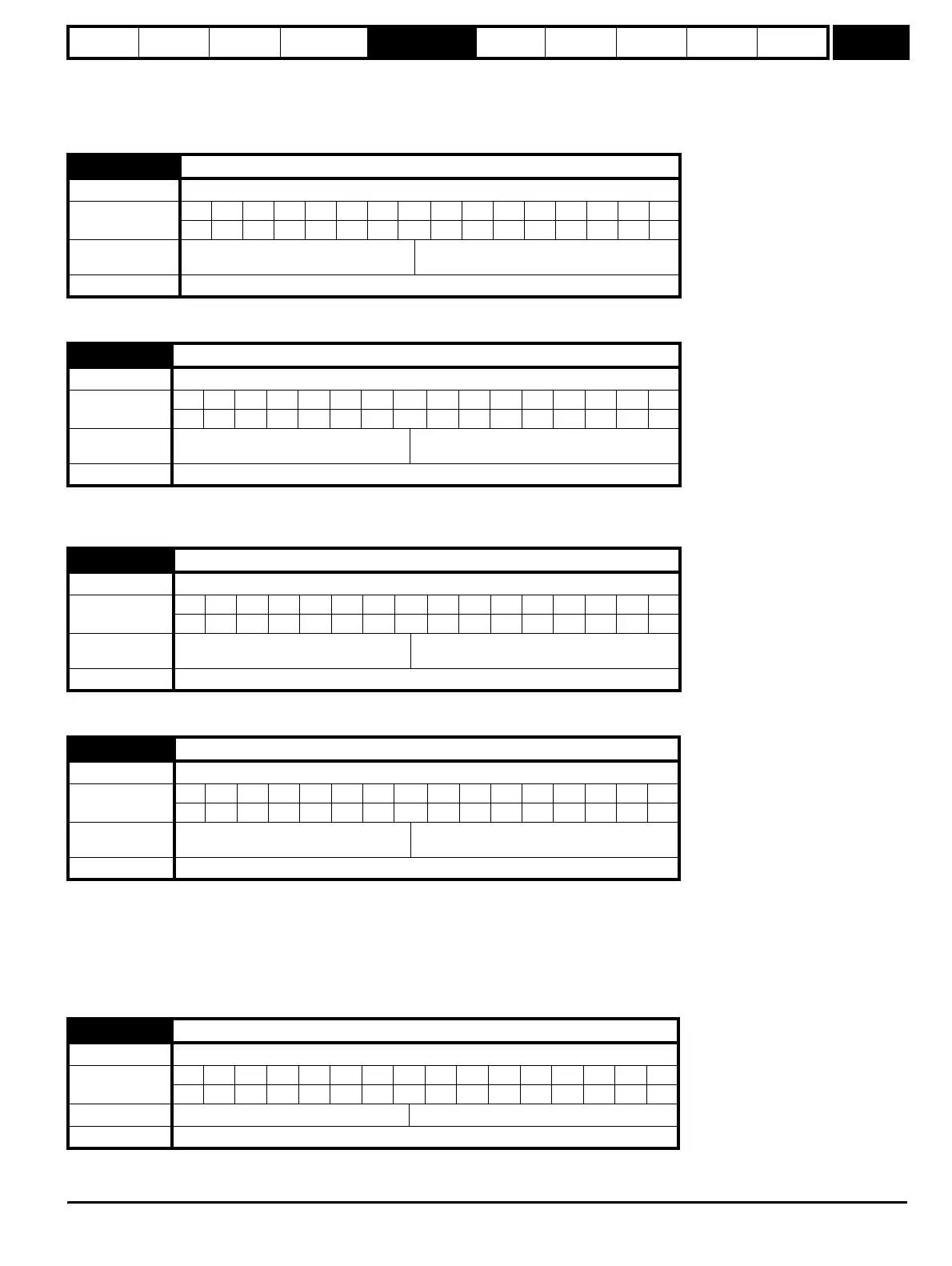

4.17 Reactive current

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

112111

Range

Open-loop, Closed-loop vector, Servo,

Regen

±DRIVE_CURRENT_MAX A

Update rate 4ms write

4.18 Overriding current limit

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111 1 1 1

Range

Open-loop, Closed-loop vector, Servo,

Regen

0 to TORQUE_PROD_CURRENT_MAX %

Update rate Background write

4.19 Overload accumulator

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

11 1 1 1

Range

Open-loop, Closed-loop vector, Servo,

Regen

0 to 100.0 %

Update rate Background write

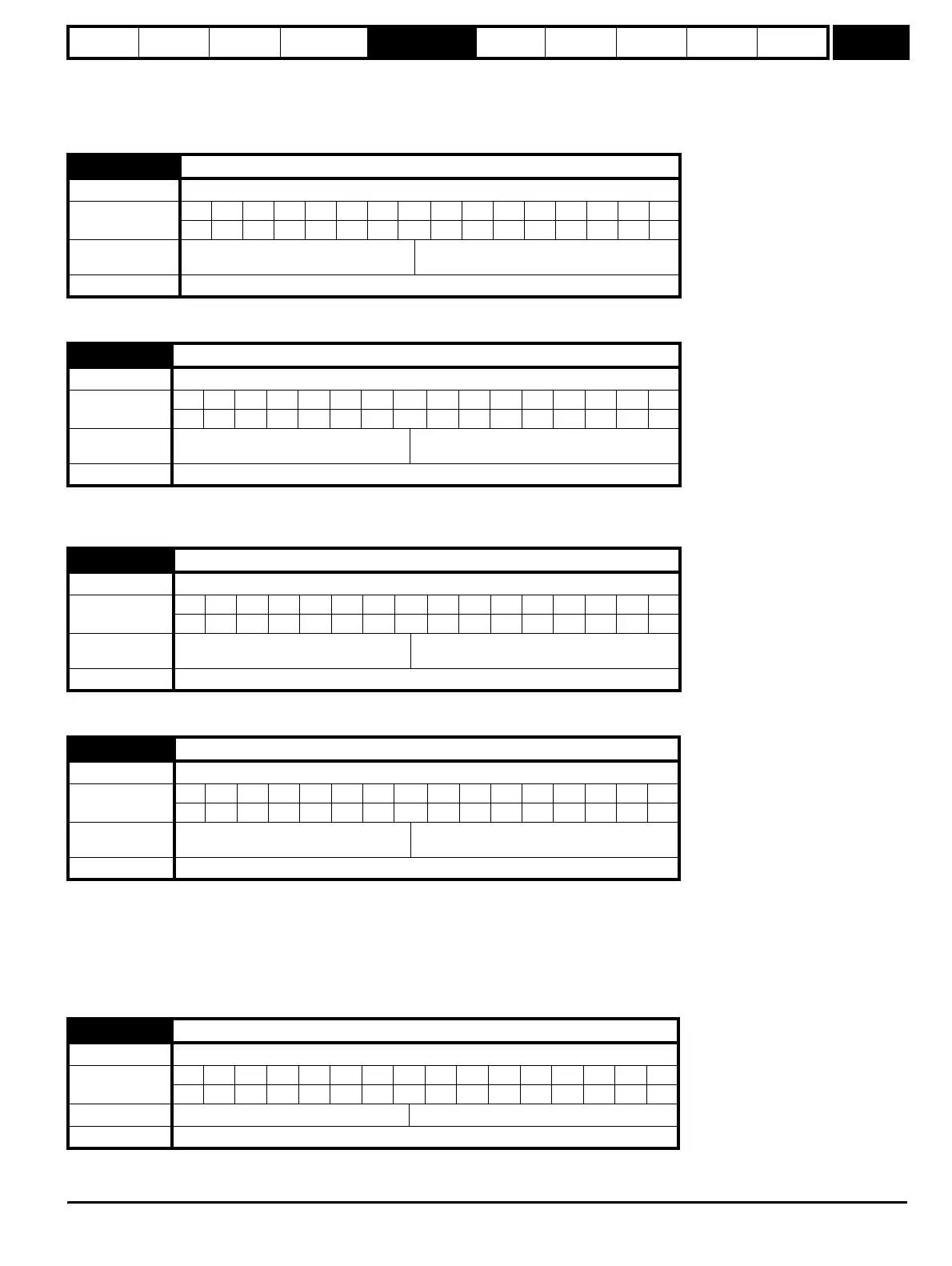

4.20 Percentage load

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111111

Range

Open-loop, Closed-loop vector, Servo

Regen

±USER_CURRENT_MAX %

Update rate Background write

4.22 Inertia compensation enable

Drive modes Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Default Closed-loop vector, Servo 0

Update rate Background read

http://nicontrols.com

Loading...

Loading...