Menu 3

All modes

Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

64 Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 7

power supply is too low (see Pr 3.40). If the encoder gives this information the comms resolution should be set up to include this bit whether it is being

monitored by the drive or not.

It is possible for the drive to set up this parameter automatically from information obtained from the encoder via Hiperface or EnDat interfaces (see

Pr 3.41).

This parameter defines the baud rate for the encoder comms when using SSI or EnDat encoders. However, a fixed baud rate of 9600 baud is used

with HIPERFACE encoders and this parameter has no effect.

Any baud rate can be used when encoder comms is used with a SINCOS encoder to obtain the absolute position during initialisation. When encoder

comms is used alone(EnDat or SSI selected with Pr 3.38) the time taken to obtain the comms position must be 160µs or less, otherwise the drive

initiates an Enc4 trip.

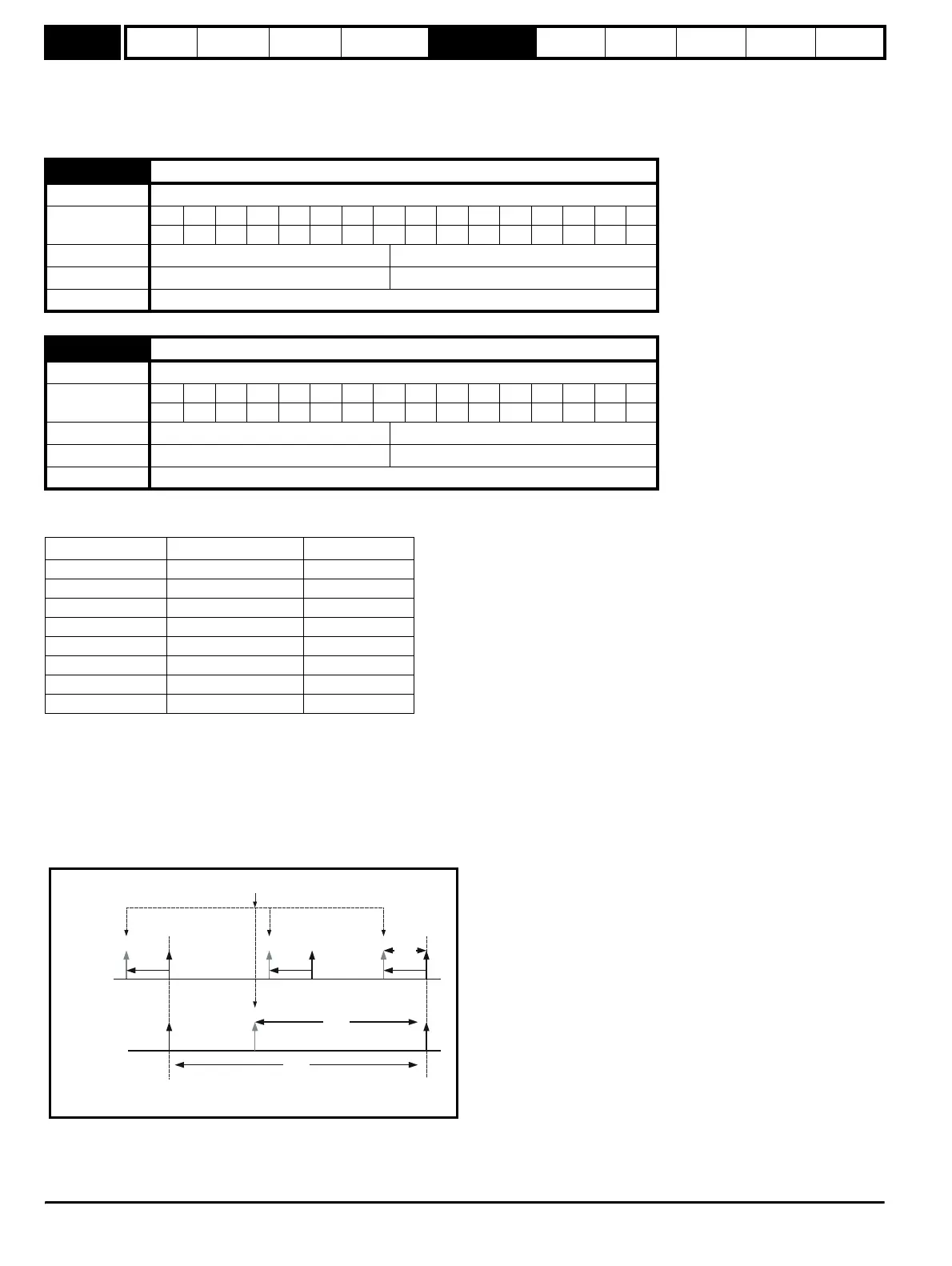

There is a delay obtaining the position from an encoder using comms alone. The length of this delay affects the sample rate and timing of the position

used by the drive for control and the position passed to Solutions Modules. If for an EnDat encoder the position within one turn can be obtained in

30µs and the whole comms message including CRC can be obtained in 60µs then fast sampling is used, otherwise slow sampling is used as shown

below. If for an SSI encoder the whole position can be obtained in 30µs fast sampling is used. In each case the position is sampled within the encoder

at the start of the comms message from the drive.

In the example the current/torque sampling rate is 4kHz, but this will change if a different switching frequency is selected. If fast sampling is used the

control position used to define the drive reference frame is obtained every current/torque control sample and the position passed to Solutions

Modules is obtained 20µs before the datum point where other types of encoders are sampled. If slow sampling is used both the control position and

the position passed to Solutions Modules is obtained 150µs before the datum. When fast sampling is used the delay introduced into the control

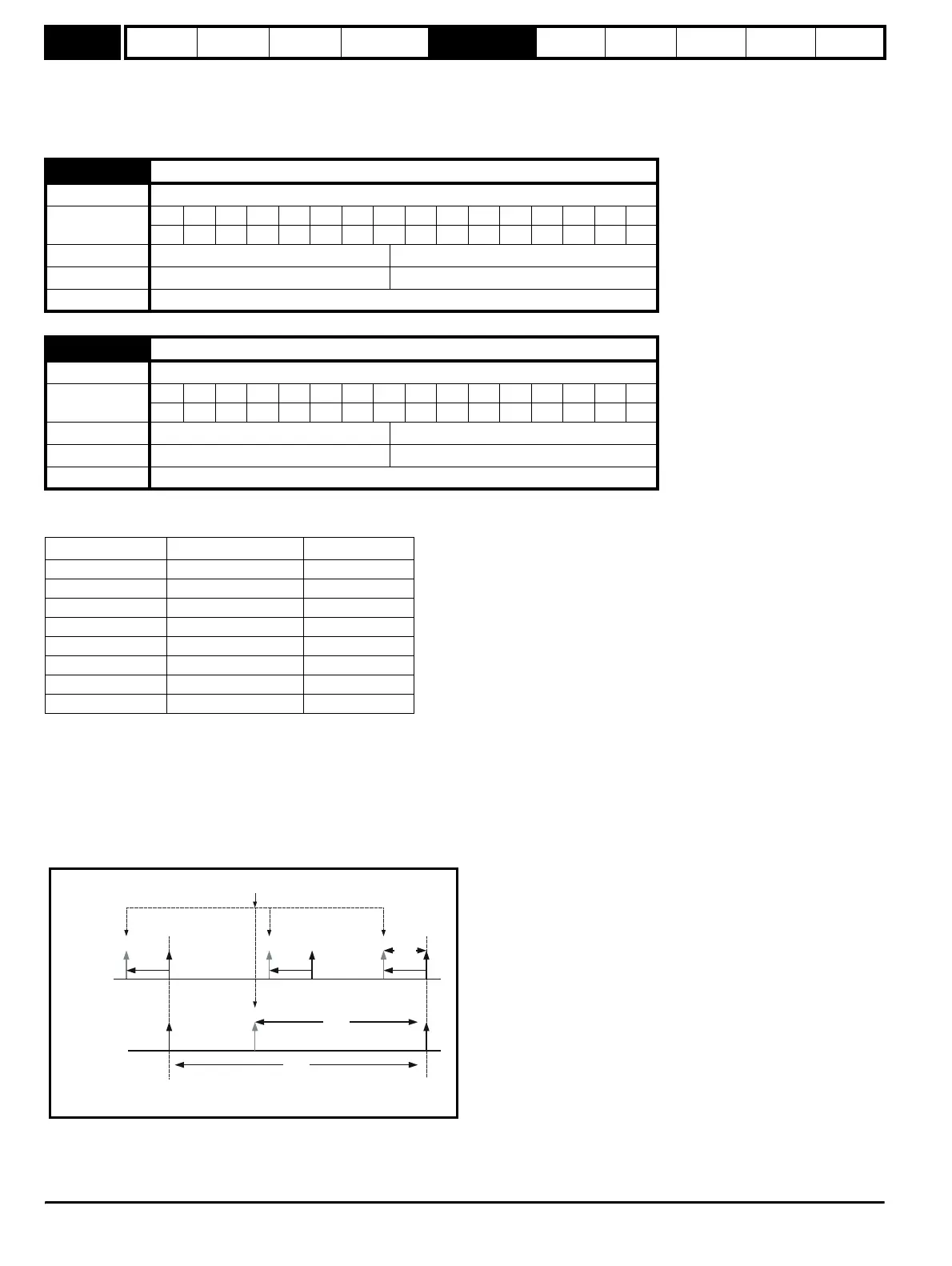

3.36

Drive encoder supply voltage

Drive modes Open-loop, Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1111

Range Open-loop, Closed-loop vector, Servo 0 to 2

Default Open-loop, Closed-loop vector, Servo 0

Update rate Background read

3.37

Drive encoder comms baud rate

Drive modes Open-loop, Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1111

Range Open-loop, Closed-loop vector, Servo 0 to 7

Default Open-loop, Closed-loop vector, Servo 2

Update rate Background read (Only has any effect when the drive is disabled)

Parameter value Parameter string Baud rate

0 100 100k

1 200 200k

2 300 300k

3 400 400k

4 500 500k

5 1000 1M

6 1500 1.5M

7 2000 2M

Slow

Sampling

Fast

Sampling

250 s

µ

Datum

Point

Datum

Point

150 s

µ

20 s

µ

Start of comms messages and encoder position sampling point

http://nicontrols.com

Loading...

Loading...