Menu 3

All modes

Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

70 Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 7

A sliding window filter may be applied to the feedback taken from the drive encoder. This is particularly useful in applications where the drive encoder

is used to give speed feedback for the speed controller and where the load includes a high inertia, and so the speed controller gains are very high.

Under these conditions, without a filter on the feedback, it is possible for the speed loop output to change constantly from one current limit to the other

and lock the integral term of the speed controller.

It should be noted that if this filter is used where the speed feedback is provided by an EnDat or SSI encoder connected directly to the drive, it may be

necessary for the encoder to provide at least 6 bits of turns information. This is not a problem when the position is defined by the absolute position

from the encoder at initialisation and then accumulated delta positions (Pr 3.39=0), however, if the absolute position is taken directly from the encoder

(Pr 3.39 > 0) the encoder must provide at least 6 bits of turns information. If this filter is not used (i.e. Pr 3.42=0) turns information from the encoder is

not required.

The drive encoder input can be used as a reference to control a drive parameter. The drive encoder reference parameter (Pr 3.45) gives the speed of

the encoder input as a percentage of the maximum drive encoder reference provided that the number of encoder lines per revolution (Pr 3.34) has

been set up correctly. This may then be scaled and routed to any non-protected drive parameter.

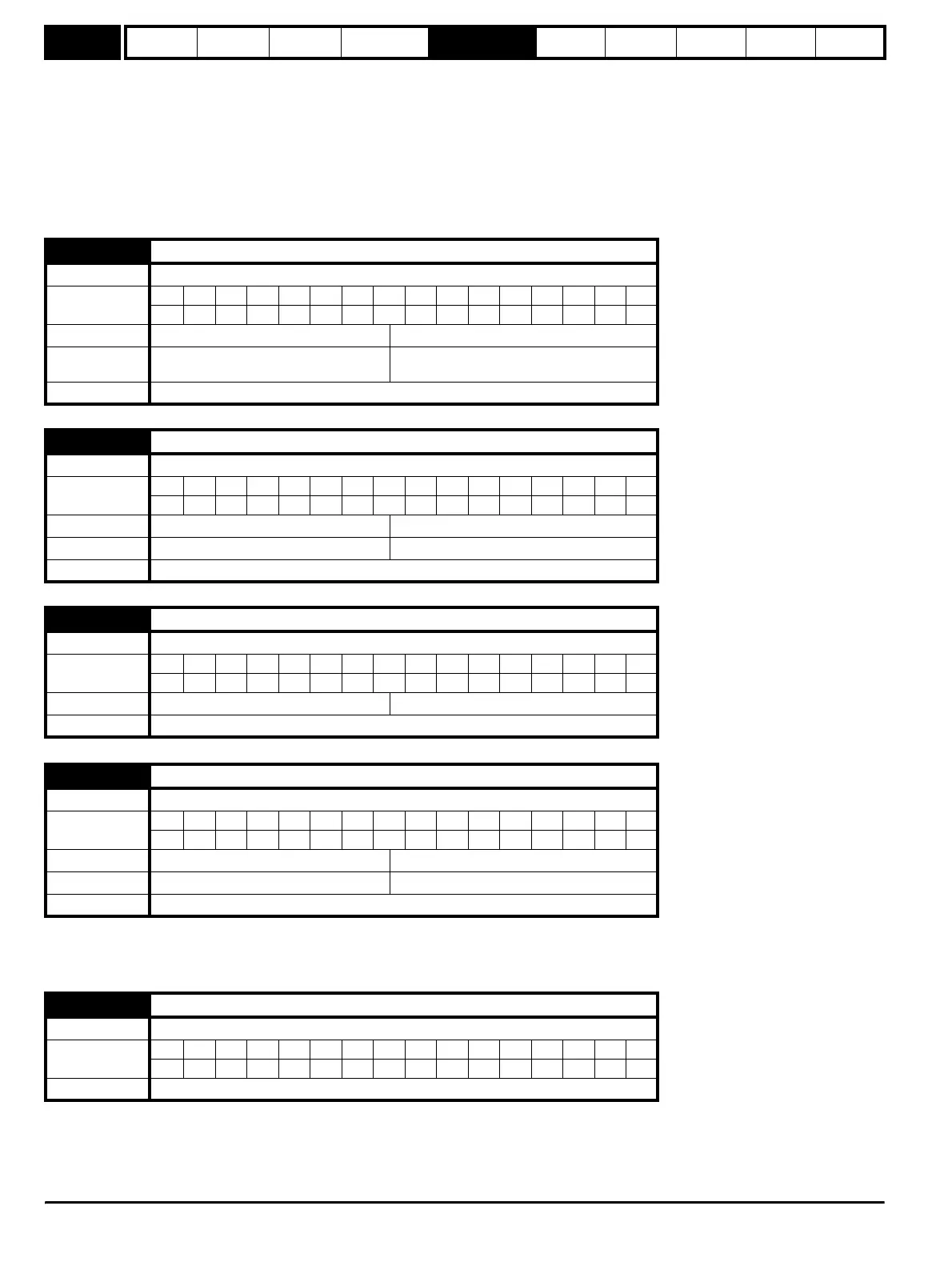

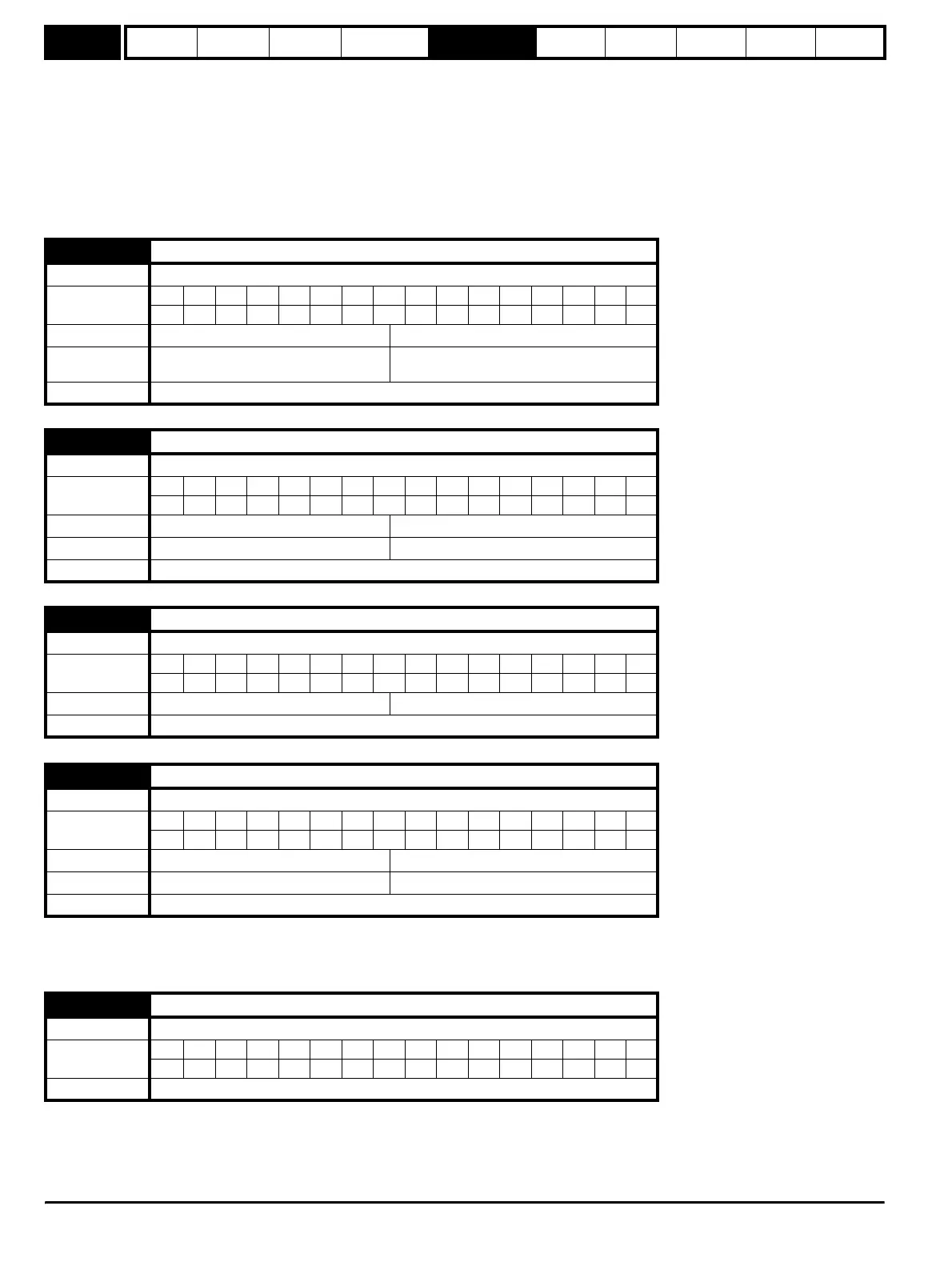

3.43

Maximum drive encoder reference

Drive modes Open-loop, Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Range Open-loop, Closed-loop vector, Servo 0 to 40,000 rpm

Default

Open-loop, Closed-loop vector

Servo

1,500

3,000

Update rate Background read

3.44

Drive encoder reference scaling

Drive modes Open-loop, Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

3111

Range Open-loop, Closed-loop vector, Servo 0.000 to 4.000

Default Open-loop, Closed-loop vector, Servo 1.000

Update rate Background read

3.45

Drive encoder reference

Drive modes Open-loop, Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

11 1

Range Open-loop, Closed-loop vector, Servo ±100.0%

Update rate 4ms write

3.46

Drive encoder reference destination

Drive modes Open-loop, Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1 2 1111

Range Open-loop, Closed-loop vector, Servo Pr 0.00 to Pr 21.50

Default Open-loop, Closed-loop vector, Servo Pr 0.00

Update rate Read on reset

3.47 Re-initialise position feedback

Drive modes Open-loop, Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Update rate Background read

http://nicontrols.com

Loading...

Loading...