Menu 3

Closed-loop

Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

60 Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 7

The encoder can be aligned statically by connecting the motor to a DC power supply as shown:

The motor will move to one of a number of positions defined by the number of motor pole pairs (i.e. 3 positions for a six pole motor, etc.). The encoder

should be adjusted so that the U commutation signal is high, W is low and V is toggling in one of these positions.

Any other feedback device

The alignment required between the no-load motor voltages and the commutation signals for Pr 3.25 = 0 is shown in the diagram below for a 2 or 4

pole motor. For higher numbers of poles 0o should still be aligned as shown, but one electrical cycle shown corresponds to 360o / (Number of poles /

2). The encoder can be aligned statically by connecting the motor to a DC power supply as already shown. The motor will move to one of a number of

positions defined by the number of motor pole pairs (i.e. 3 positions for a six pole motor, etc.). The encoder should be adjusted so that the position

displayed by the drive is n x 65536 / (Number of poles / 2), where n = 0, 1, ... (Number of poles / 2)

0, drv: Drive encoder

The position feedback from the encoder connected to the drive itself is used to derive the speed feedback for the speed controller and to calculate

the motor rotor flux position.

1, Slot1: Solutions Module in slot 1

The position feedback from the Solutions Module in Solutions Module slot 1 is used to derive the speed feedback for the speed controller and to

calculate the motor rotor flux position. If a position feedback category Solutions Module is not fitted in slot 1 the drive produces an EnC9 trip.

2, Slot2: Solutions Module in slot 2

3, Slot3: Solutions Module in slot 3

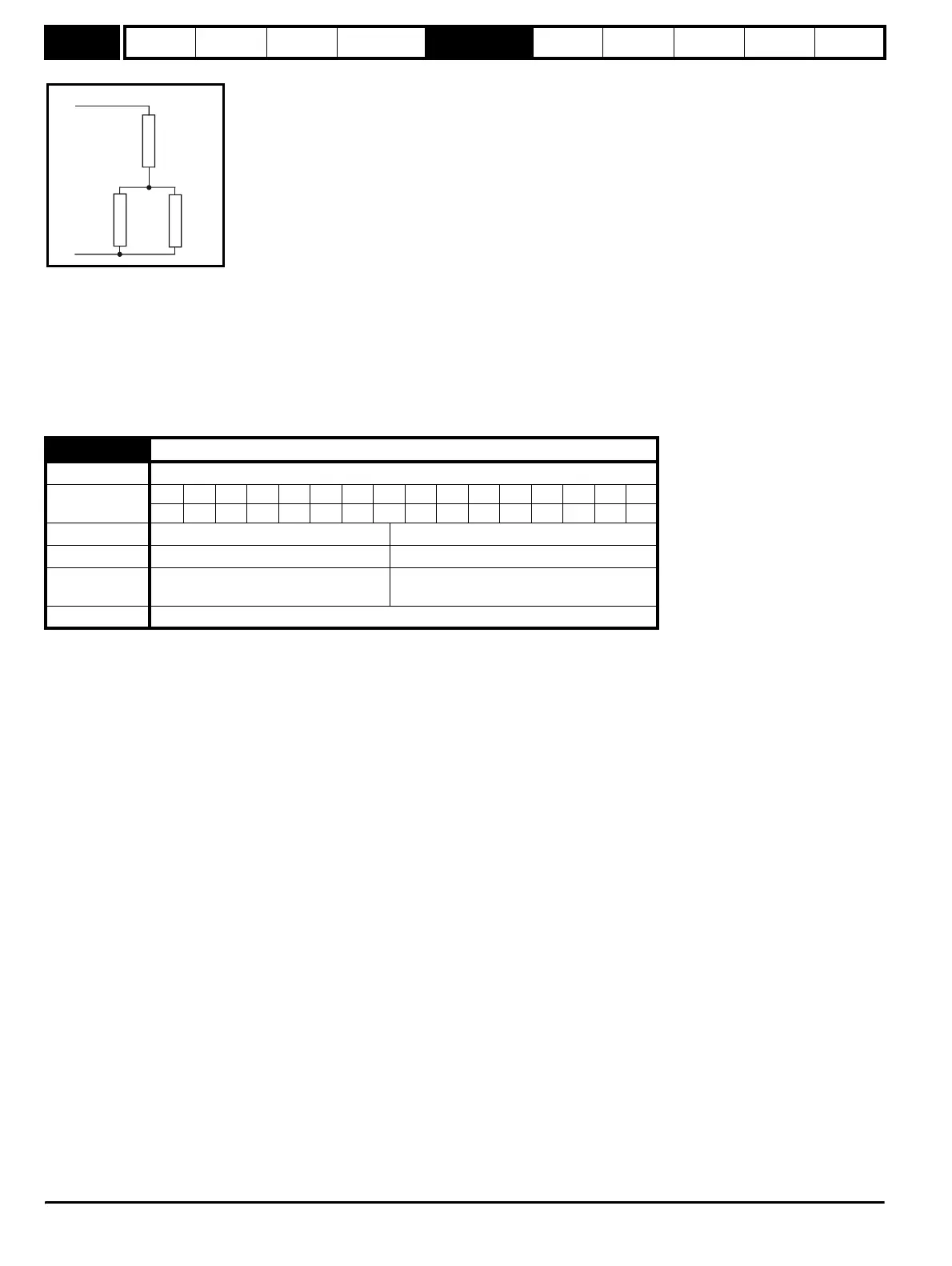

3.26

Speed feedback selector

Drive modes Closed-loop vector, Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1111

Range Closed-loop vector, Servo 0 to 3

Default Closed-loop vector, Servo 0

Second motor

parameter

Closed-loop vector, Servo Pr 21.21

Update rate Background read (Only has any effect when the drive is disabled)

_

U

V

http://nicontrols.com

Loading...

Loading...