Menu 3

All modes

Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

68 Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 7

+These trips can be enabled/disabled by Pr 3.40

1. If the terminations are not enabled on the A, B or Z inputs the wire break system will not operate. (Note that as default the Z input terminations

are disabled to disable wire break detection on this input.)

2. Phase error for a servo type encoder is to detect that the incremental pulses have been counted incorrectly. The error is detected if the

incremental position moves by 10° with respect to the position defined by the UVW commutation signals. The trip is initiated if the error is

detected for 10 consecutive samples.

3. Phase error for SinCos encoders with comms is detected by interrogating the encoder every second via comms to compare the incremental

position determined from the sine waves with the incremental position via comms. If the error is greater than 10° for 10 consecutive samples the

trip is initiated.

4. Incorrect encoder phasing is detected if the motor reaches half of the speed defined by SPEED_FREQ_MAX and the phasing error is larger

enough for the motor to accelerate uncontrollably. It can be disabled by setting Pr 3.08 to any value greater than zero.

5. This trip can also be caused when data is transferred between the encoder and an option module, such as an SM-Applications module, and an

error other than those covered by Enc5 or Enc6 occurs.

Wire-break detection

It may be important to detect a break in the connections between the drive and the position feedback device. This feature is provided for most

encoder types either directly or indirectly as listed below.

Encoder initialisation

Encoder initialisation will occur as follows: at drive power-up, when requested by the user via Pr 3.47, when trips PS.24V or Enc1 to Enc8 or Enc11 to

Enc17 are reset. Initialisation causes an encoder with comms to be re-initialised and auto-configuration to be performed if selected. After initialisation

Ab.Servo, Fd.Servo and Fr.Servo encoders will use the UVW commutations signals to give position feedback for the first 120deg (electrical) of

rotation when the motor is restarted.

A delay is provided during intialisation for some encoders to allow the encoder to be ready to provide position information after it has powered up. The

delay is provided during initialisation because this occurs during drive power-up and after encoder power supply trips are reset. The delays are as

follows:

SC, SC.Hiper, SC.EnDat,

SC.SSI, EnDat, SSI

Initialisation has failed due to a comms error. Enc7

SC.Hiper, SC.EnDat, EnDat

Auto-configuration has been requested by changing Pr 3.41, but

an initialisation has not occurred to perform auto-configuration.

Enc8

All

Speed feedback selected from an option slot that does not have

a position feedback category option module fitted

Enc9

All (Servo mode only)

Incorrect encoder phasing

(4)

Enc10

SC, SC.Hiper, SC.EnDat, SC.SSI Failure of Analog position alignment during encoder initialisation Enc11

SC.Hiper

The encoder type could not be identified during auto-

configuration

Enc12

SC.EnDat, EnDat

The number of encoder turns read from the encoder during

auto-configuration is not a power of 2

Enc13

SC.EnDat, EnDat

The number of bits defining the encoder position within a turn

read from the encoder during auto-configuration is too large.

Enc14

SC.Hiper, SC.EnDat, EnDat

The number of periods per revolution is either less than 2 or

greater than 50000 when read or calculated from the encoder

data during auto-configuration.

Enc15

SC.EnDat, EnDat The number of comms bits per period are larger than 255. Enc 16

SC.Hiper, SC.EnDat, EnDat

This is a rotary encoder (Pr 3.39=1 or 2) and the lines per

revolution read from this encoder are not a power of two.

Enc 17

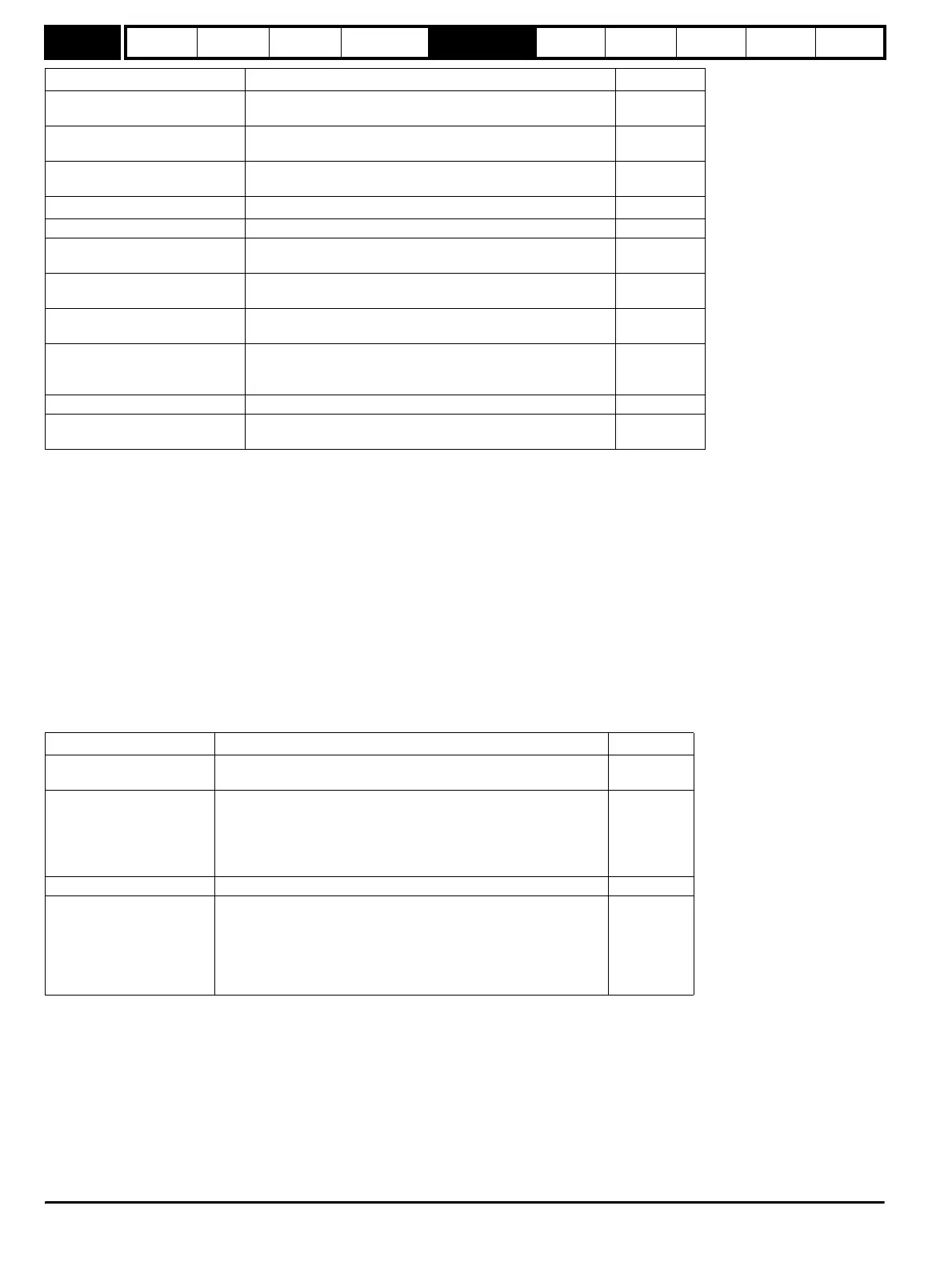

Device Detection method Drive Trip

Ab, Fd, Fr, Ab.Servo,

Fd.Servo, Fr.Servo

Hardware detectors on the A(F), B(D,R) and Z signal detect a wire

break.

Enc2

SC,

SC.Hiper,

SC.EnData,

SC.SSI

The differential levels of the sine and cosine waveforms are

available to the drive. The drive detects wire break if Sine

2

+Cosine

2

is less than the value produced by two valid waveforms with a

differential peak to peak magnitude of 0.25V (1/4 of the nominal

level). This detects wire break in the sine and cosine connections.

Enc2

SC.Hiper, SC.EnDat, EnDat Wire break in the comms link is detected by a CRC or timeout error. Enc4, Enc5

SSI

Wire break detection is difficult with these devices. However, if

power supply monitoring is enabled the drive will be looking for a

one at the start of the message and a zero to indicate that the power

supply is okay. If the clock stops or the data line is disconnected the

data input to the drive may stay in one state or the other and cause a

trip.

Enc5, Enc6

Encoders Reason for error Drive trip

http://nicontrols.com

Loading...

Loading...