Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

Menu 4

Unidrive SP Advanced User Guide 97

Issue Number: 7 www.controltechniques.com

Regen

The defaults Kp and Ki gains should be suitable for the standard regen inductors. If the input inductance is significantly higher the gains should be

adjusted as described for the Closed-loop vector and Servo modes. See Pr 3.06 on page 77 for guidelines on setting the regen unit current controller

gains.

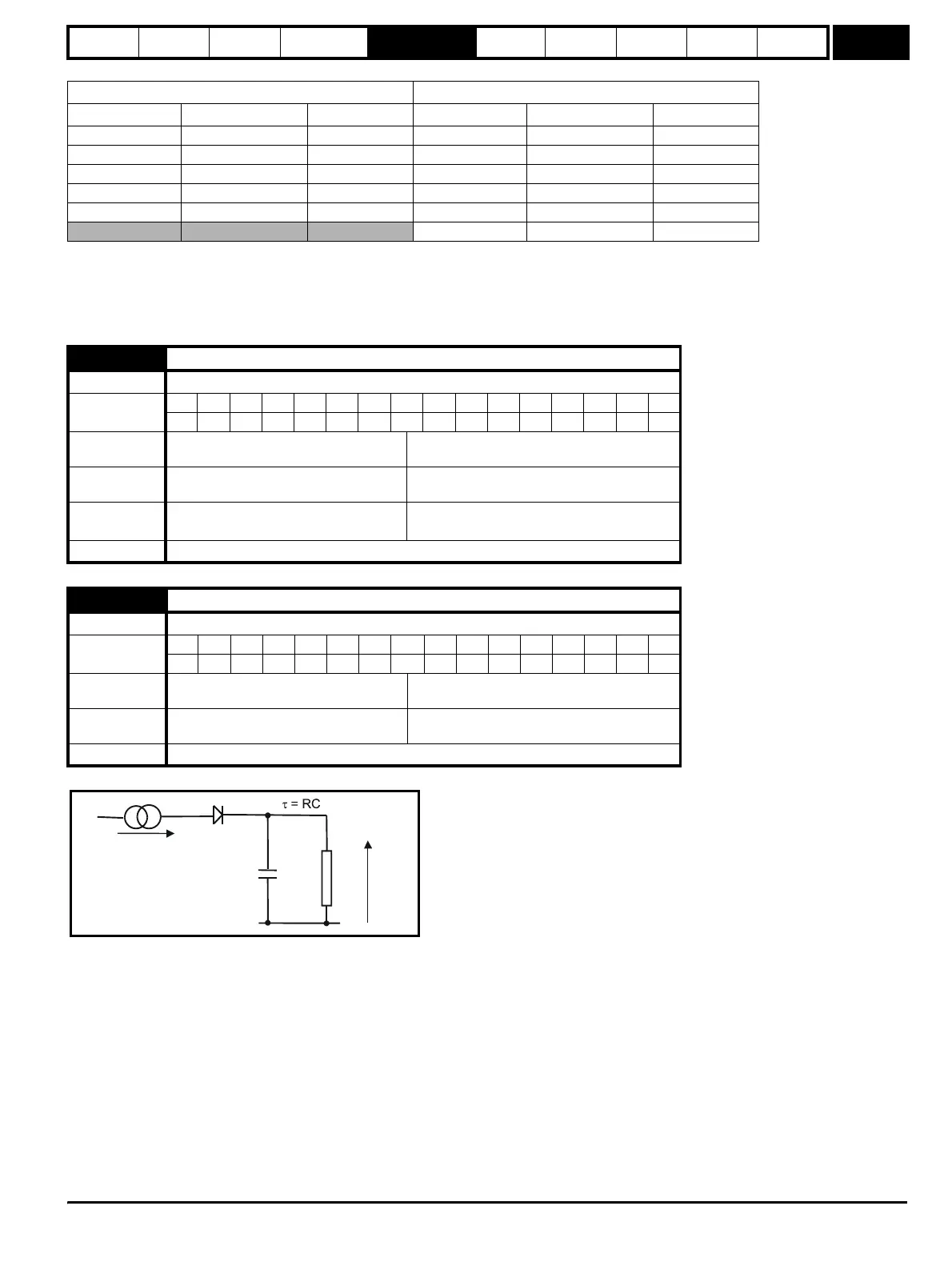

The motor is modelled thermally in a way that is equivalent to the electrical circuit shown as follows.

The temperature of the motor as a percentage of maximum temperature, with a constant current magnitude of I, constant value of K and constant

value of motor rated current (set by Pr 5.07 or Pr 21.07) after time t is given by

Temp = [I

2

/ (K x Motor rated current)

2

] (1 - e

-t/τ

) x 100%

This assumes that the maximum allowed motor temperature is produced by K x Motor rated current and that τ is the thermal time constant of the point

in the motor that reaches its maximum allowed temperature first. τ is defined by Pr 4.15. The estimated motor temperature is given by Pr 4.19 as a

percentage of maximum temperature. If Pr 4.15 has a value between 0.0 and 1.0 the thermal time constant is taken as 1.0.

If the rated current (defined by Pr 5.07 or Pr 21.07 depending on which motor is selected) is less or equal to the maximum Heavy Duty rating then

Pr 4.25 can be used to select 2 alternative protection characteristics (see diagram below). If Pr 4.25 is 0 the characteristic is for a motor which can

operate at rated current over the whole speed range. Induction motors with this type of characteristic normally have forced cooling. If Pr 4.25 is 1 the

characteristic is intended for motors where the cooling effect of motor fan reduces with reduced motor speed below half of rated speed. The maximum

value for K is 1.05, so that above the knee of the characteristics the motor can operate continuously up to 1.05% current. (In Regen mode K = 1.05

over the whole operating frequency range.)

Unidrive Unidrive SP

Switching freq Proportional gain Integral gain Switching freq Proportional gain Integral gain

3kHz Pr 4.13 x 0.5 Pr 4.14 3kHz Pr 4.13 Pr 4.14

4.5kHz Pr 4.13 x 0.75 Pr 4.14 4kHz Pr 4.13 x 1.5 Pr 4.14

6kHz Pr 4.13 Pr 4.14 6kHz Pr 4.13 x 2 Pr 4.14

9kHz Pr 4.13 x 0.75 Pr 4.14 8kHz Pr 4.13 x 2 Pr 4.14 x 1.3

12kHz Pr 4.13 Pr 4.14 12kHz Pr 4.13 x 2.6 Pr 4.14 x 1.3

16kHz Pr 4.13 x 2 Pr 4.14 x 1.3

4.15 Thermal time constant

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

111

Range

Open-loop, Closed-loop vector, Servo,

Regen

0.0 to 400.0

Default

Open-loop, Closed-loop vector, Regen

Servo

89.0

20.0

Second motor

parameter

Open-loop, Closed-loop vector, Servo,

Regen

Pr 21.16

Update rate Background read

4.16 Thermal protection mode

Drive modes Open-loop, Closed-loop vector, Servo, Regen

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1111

Range

Open-loop, Closed-loop vector, Servo,

Regen

0 to 1

Default

Open-loop, Closed-loop vector, Servo,

Regen

0

Update rate Background read

(I /(K*Motor Rated Current)

22

Temp

C

R

http://nicontrols.com

Loading...

Loading...