Menu 5

Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

114 Unidrive SP Advanced User Guide

www.controltechniques.com Issue Number: 7

0: Ur_S, Stator resistance and voltage offset measured at each start

The stator resistance (Pr 5.17) and the voltage offset (Pr 5.23) are measured and the parameters over-written each time the drive is started. This test

can only be done with a stationary machine where the flux has decayed to zero. Therefore this mode should only be used if the machine is

guaranteed to be stationary each time the drive is enabled. To prevent the test from being done before the flux has decayed there is a period of 1

second after the drive has been in the ready state during which the test is not done if the drive is re-started. In this case, previously measured values

are used. The new values of stator resistance and voltage offset are not automatically saved to EEPROM or the SMARTCARD.

1: Ur, No measurements

The stator resistance and voltage offset are not measured. The user can enter the motor and cabling resistance into the stator resistance parameter.

However this will not include resistance effects within the drive inverter. Therefore if this mode is to be used, it is best to use the auto-tuning stationary

test initially to measure the stator resistance.

2: Fd, Fixed boost mode.

Neither the stator resistance nor the voltage offset are used, instead a fixed characteristic with boost applied as defined by Pr 5.15 is used.

3: Ur_Auto, Stator resistance and voltage offset measured at first drive enable

The stator resistance and voltage offset are measured once, the first time the drive is enabled. After the test has been completed successfully the

mode is changed to Ur mode. The stator resistance and voltage offset are written to the parameters for the currently selected motor map and these

parameters along with this parameter are saved in the EEPROM (and the SMARTCARD if Pr 11.42 = 3 or 4). If the test fails the stator resistance and

voltage offset are not updated, the mode is changed to Ur, but no parameters are saved.

4: Ur_I, Stator resistance and voltage offset measured at each power-up

The stator resistance and voltage offset are measured when the drive is first enabled and at each subsequent power-up. The new values of stator

resistance and voltage offset are not automatically saved to EEPROM or the SMARTCARD.

5 E: Square law characteristic

Neither the stator resistance nor the voltage offset are used, instead a fixed square law characteristic with boost applied as defined by Pr 5.15 is used.

This parameter defines the action taken on enable as follows:

0: nonE

No action.

1. Ph Enl

A minimal movement phasing test is performed each time the drive is enabled (i.e. changes from the inhibit state to either the stop or run state). The

test can be used to determine the phasing angle for an absolute or non-absolute type encoder. If the test is completed successfully the drive changes

to the stop or run state as appropriate. The phasing angle parameter is updated to the correct value, but it is not saved to EEPROM or the SMART

card.

2. Ph Init

A minimal movement phasing test is performed the first time the drive is enabled after power-up. The test will only be performed again on enable if the

position feedback device(s) have been re-initialised. Re-initialisation occurs for example after a trip specifically related to an encoder where position

information may have been lost. Initialisation occurs when parameter 03.48 changes from zero to one. The phasing angle parameter is updated to the

correct value, but it is not saved to EEPROM or the SMART card.

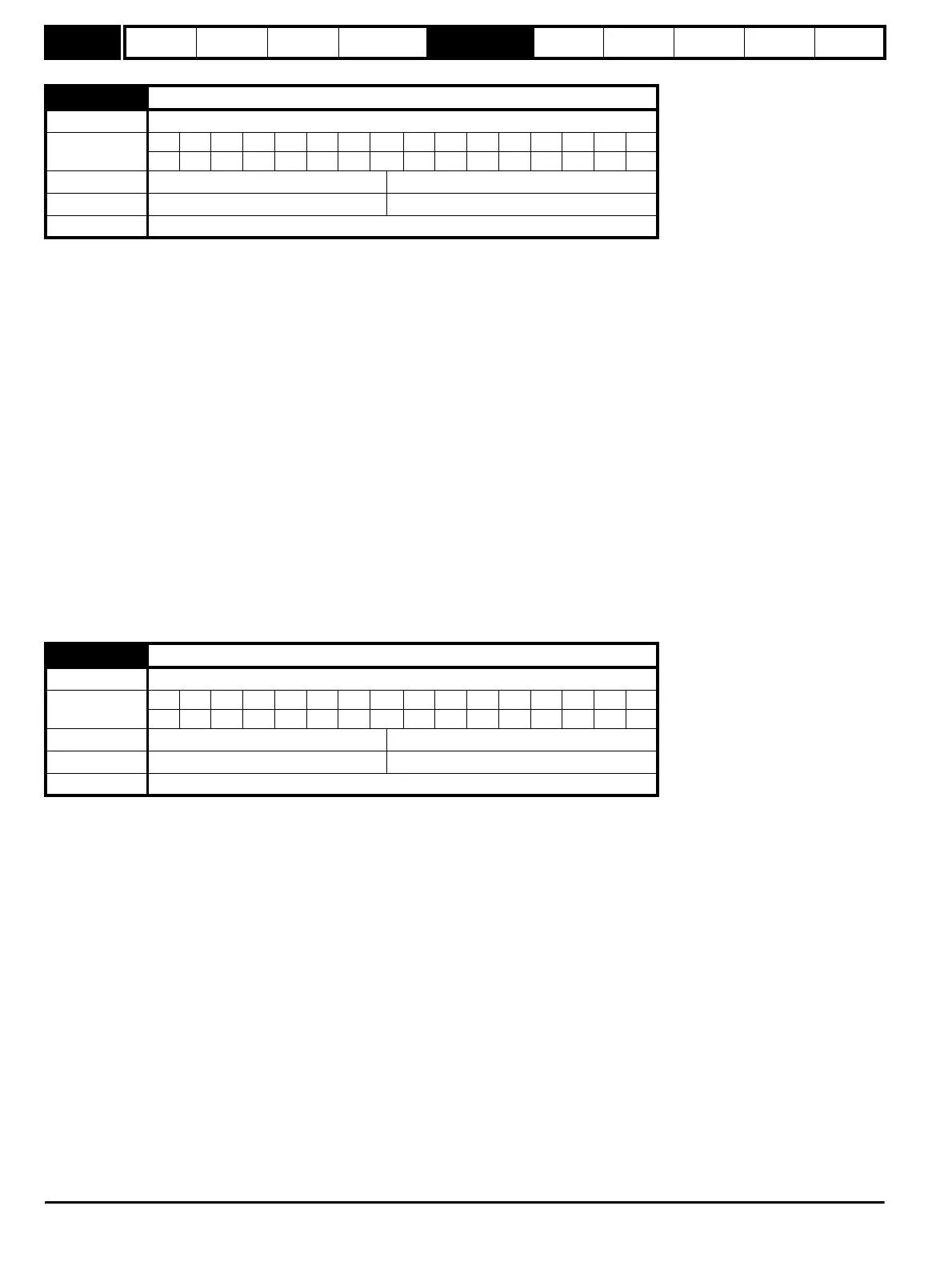

5.14 Voltage mode select

Drive modes Open-loop

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1111

Range Open-loop 0 to 5

Default Open-loop 4

Update rate Background read

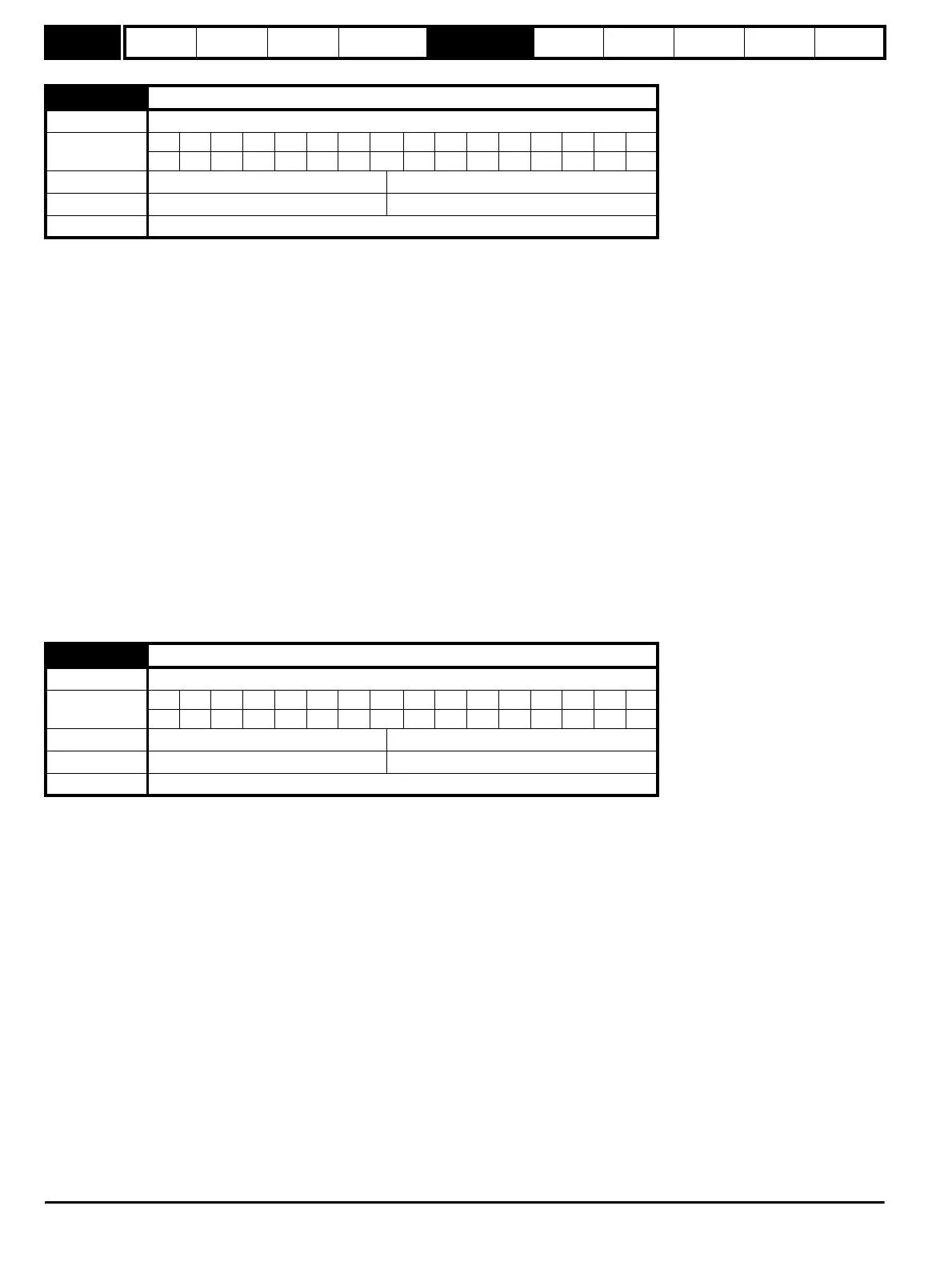

5.14 Action on enable

Drive modes Servo

Coding

BitSP FI DETEVMDPNDRANCNVPTUSRWBUPS

1111

Range Servo 0 to 2

Default Servo 0

Update rate Background read

http://nicontrols.com

Loading...

Loading...