Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

Menu 3

Closed-loop

Unidrive SP Advanced User Guide 59

Issue Number: 7 www.controltechniques.com

3: Closed-loop vector mode without position feedback with no maximum speed limit

In some applications using closed-loop vector control the maximum speed of the system is above the speed at which the encoder feedback

frequency is too high to be used by the drive. For these type of applications Pr 3.24 should be set to 2 for low speed operation and 3 for high

speed operation. It should be noted that the drive no longer checks that the maximum encoder frequency cannot be exceeded in closed-loop

vector control, and so the user must ensure that Pr 3.24 is set to 3 before the encoder frequency limit is reached.

If the drive encoder lines per rev (Pr 3.34) is set to a value that is not a power of 2 and the drive encoder type (Pr 3.38) is used to select any type

of SINCOS encoder this parameter is forced to zero. This is because the extra processing time required to support the feedback device would not

allow enough time for the closed- loop vector algorithm without position feedback to be executed. It should be noted that if the algorithm without

position feedback is active that the sample rate for 6 and 12kHz operation is reduced from 12kHz to 6kHz (see Pr 5.37).

The phase angle between the rotor flux in a servo motor and the encoder position is required for the motor to operated correctly. If the phase angle is

known it can be set in this parameter by the user. Alternatively the drive can automatically measure the phase angle by performing a phasing test (see

Pr 5.12 on page 109). When the test is complete the new value is written to this parameter. The encoder phase angle can be modified at any time and

becomes effective immediately. This parameter has a factory default value of 0.0, but is not affected when defaults are loaded by the user.

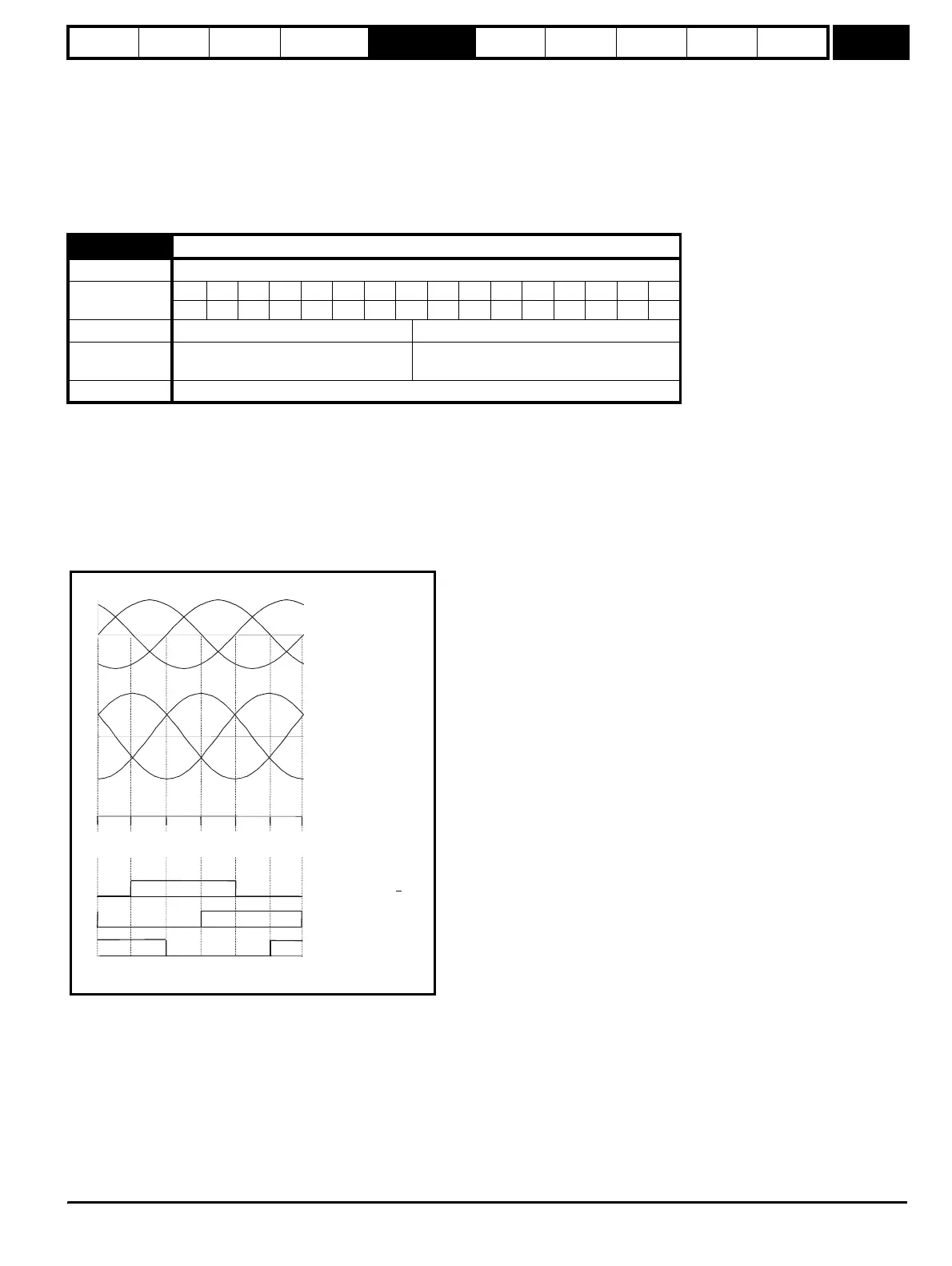

The alignment required for zero encoder phase angle (i.e. Pr 3.25 = 0.0) is given below for different feedback devices. Forward rotation of the motor

is produced when Vu leads Vv leads Vw. Although it is not essential, forward rotation of a motor is normally defined as clockwise when looking at the

motor shaft end. When the motor is rotating forwards the motor speed is shown as positive and the position increases.

Encoder with commutation signals (Ab.Servo, Fd.Servo, Fr.Servo)

The alignment required between the no-load motor voltages and the commutation signals for Pr 3.25 = 0 is shown in the following diagram below:

3.25

Encoder phase angle

Drive modes Servo

Coding

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

11 111

Range Servo 0.0 to 359.9 ° electrical

Second motor

parameter

Servo Pr 21.20

Update rate Background read

Vwu

VvwVuv

Vw

Vv

Vu

No load phase

voltages

No load line

voltages

U Encoder commutation

signals (high = U > U)

V

W

Encoder alignment for zero encoder phase angle

Encoder angle 180

o

120

o

60

oo

0

o

300

o

240

o

180

32768 43691 54613 0 10923 21845 32768

http://nicontrols.com

Loading...

Loading...