Parameter

structure

Keypad and

display

Parameter

x.00

Parameter

description format

Advanced parameter

descriptions

Macros

Serial comms

protocol

Electronic

nameplate

Performance

Feature look-

up table

Menu 10

Unidrive SP Advanced User Guide 167

Issue Number: 7 www.controltechniques.com

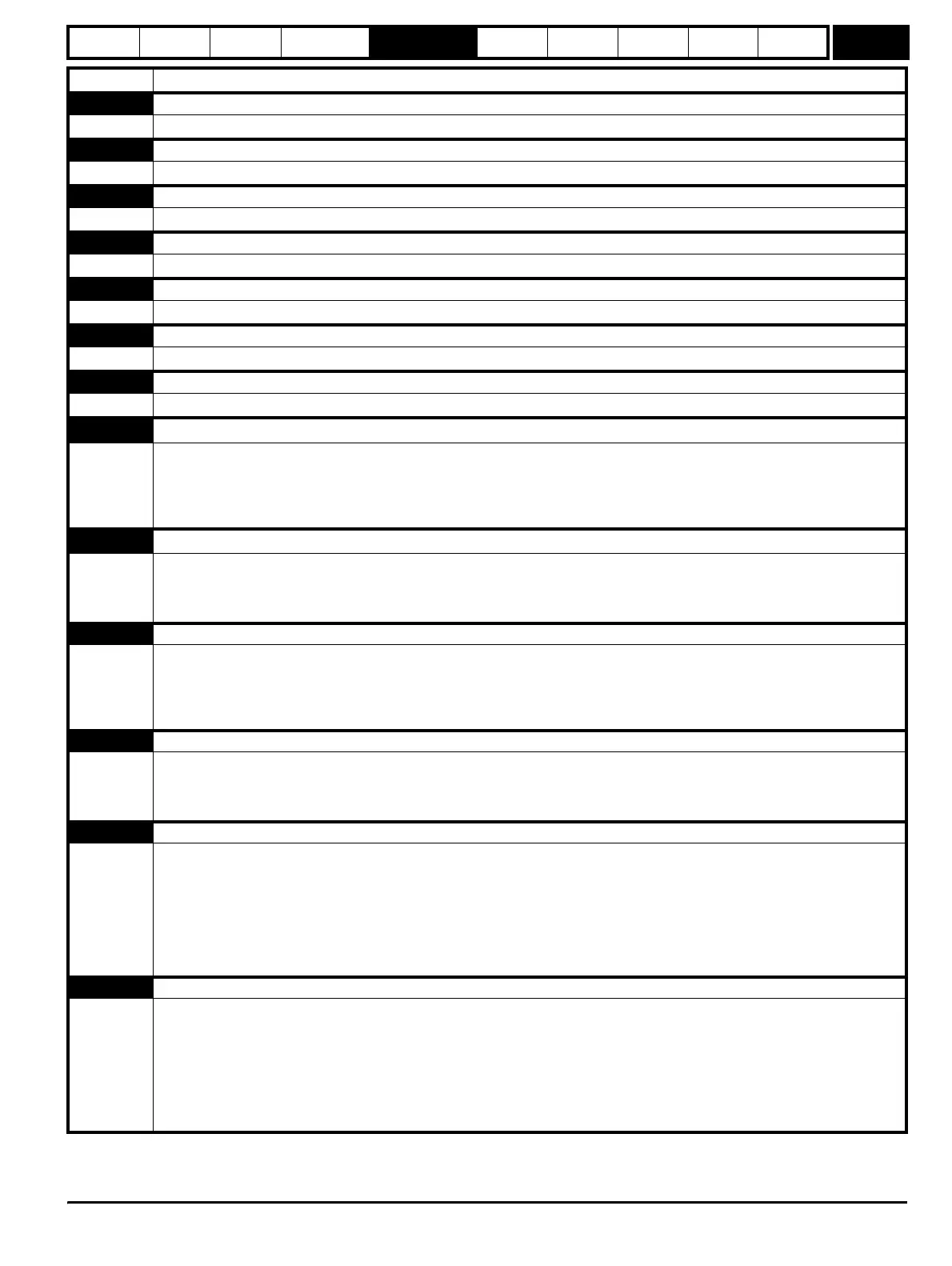

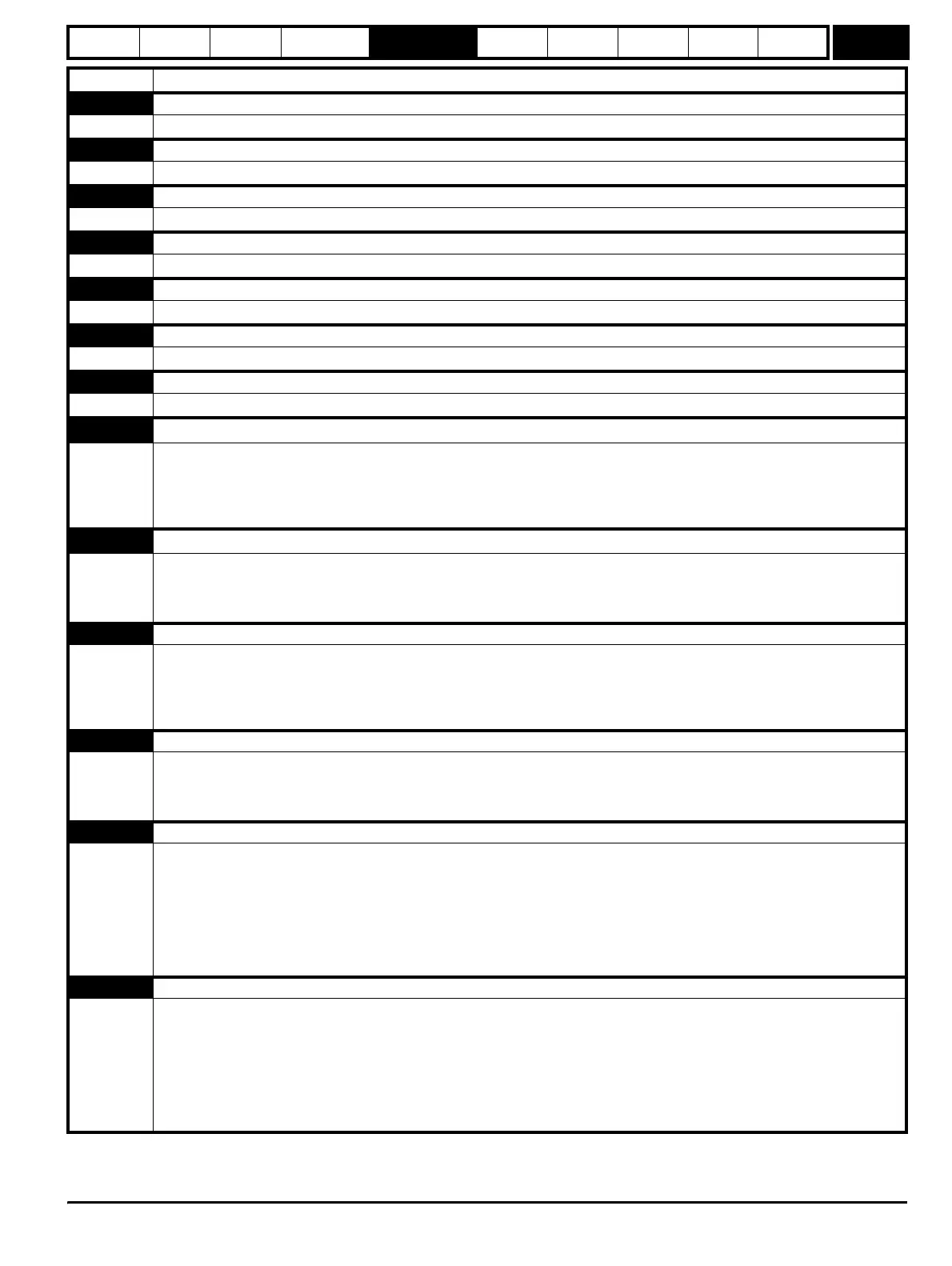

HF26 Soft start relay failed to close, soft start monitor failed or braking IGBT short circuit at power up

226 Hardware fault - return drive to supplier

HF27 Power stage thermistor 1 fault

227 Hardware fault - return drive to supplier

HF28 Power stage thermistor 2 fault or internal fan fault (size 3 only)

228 Hardware fault - return drive to supplier

HF29 Control board thermistor fault

229 Hardware fault - return drive to supplier

HF30 DCCT wire break trip from power module

230 Hardware fault - return drive to supplier

HF31 Aux fan failure from power module

231 Replace auxiliary fan

HF32 Power stage - a module has not powered up in a multi-module parallel drive

232 Check AC power supply

It.AC

Output current overload timed out (I

2

t) - accumulator value can be seen in Pr 4.19

20

Ensure the load is not jammed / sticking

Check the load on the motor has not changed

Tune the rated speed parameter (closed loop vector only)

Check feedback device signal for noise

Check the feedback device mechanical coupling

It.br

Braking resistor overload timed out (I

2

t) – accumulator value can be seen in Pr 10.39

19

Ensure the values entered in Pr 10.30 and Pr 10.31 are correct

Increase the power rating of the braking resistor and change Pr 10.30 and Pr 10.31

If an external thermal protection device is being used and the braking resistor software overload is not required, set Pr 10.30 or

Pr 10.31 to 0 to disable the trip

O.CtL Drive control board over temperature

23

Check cubicle / drive fans are still functioning correctly

Check cubicle ventilation paths

Check cubicle door filters

Check ambient temperature

Reduce drive switching frequency

O.ht1 Power device over temperature based on thermal model

21

Reduce drive switching frequency

Reduce duty cycle

Decrease acceleration / deceleration rates

Reduce motor load

O.ht2 Heatsink over temperature

22

Check cubicle / drive fans are still functioning correctly

Check cubicle ventilation paths

Check cubicle door filters

Increase ventilation

Decrease acceleration / deceleration rates

Reduce drive switching frequency

Reduce duty cycle

Reduce motor load

Oht2.P Power module heatsink over temperature

105

Check cubicle / drive fans are still functioning correctly

Check cubicle ventilation paths

Check cubicle door filters

Increase ventilation

Decrease acceleration / deceleration rates

Reduce drive switching frequency

Reduce duty cycle

Reduce motor load

Trip Diagnosis

http://nicontrols.com

Loading...

Loading...