www.dtec.net.au

Chapter 14: Inputs- Using

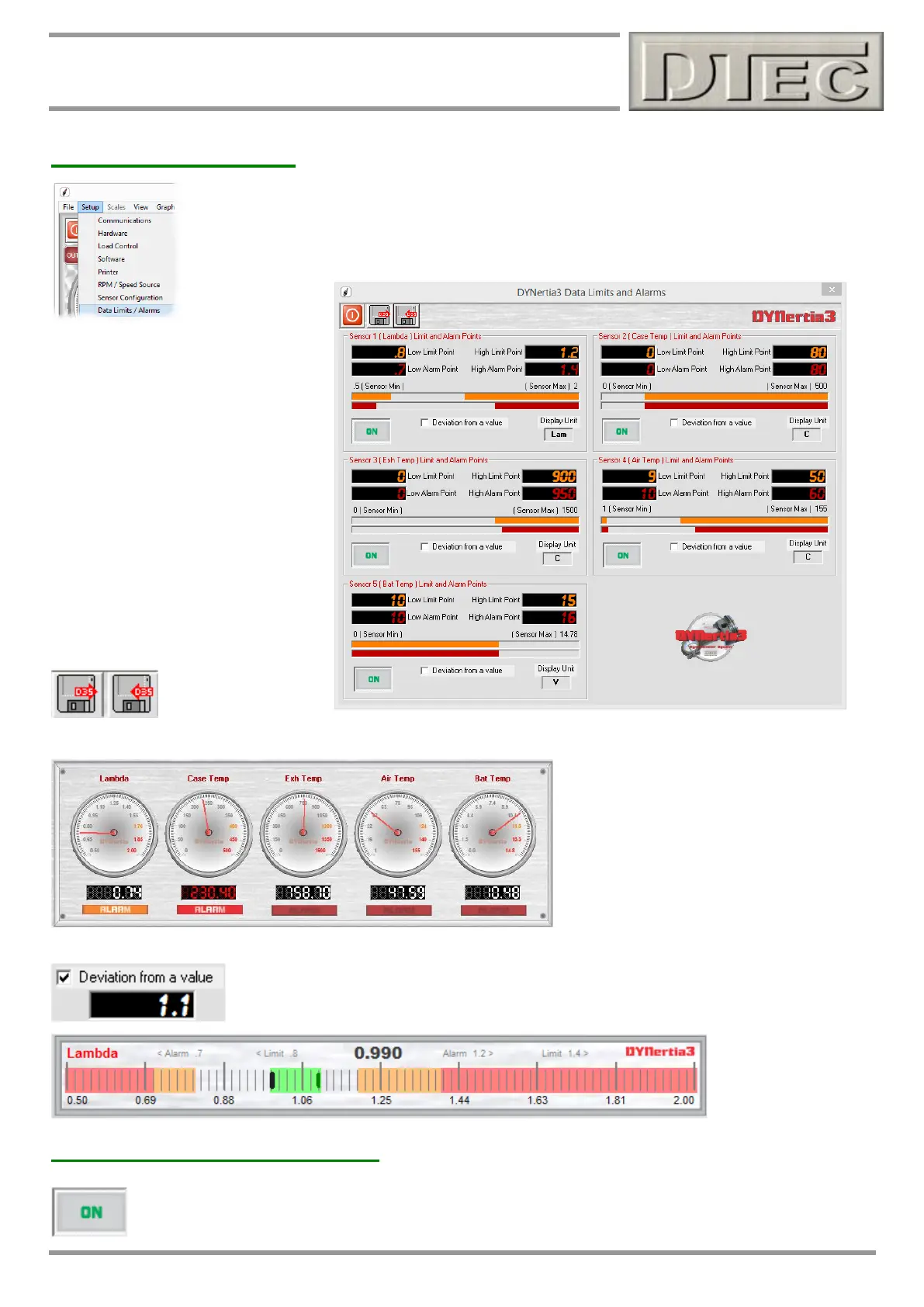

Sensor Alarm Points

Input sensors can have alarm and limit conditions attached that will turn the warning lamps either

red or orange upon triggering. This can be used for detecting damaging conditions like overheating

or even used to signify when conditions are acceptable for repeatable testing i.e. when engine

temperature is within a certain range.

Note: When viewing the data via

‘Data Channels’ Window the alarms

only apply if ‘unprocessed mV’ is not

selected to be displayed.

The alarm lamps appear on most

display screen during testing and

monitoring.

Settings also apply when viewing via

the monitoring dials on the main Dyno

screen (‘Gauges’ button is selected or

performing a run).

As shown below, the alarm lamps will

be either orange or red depending on if

the input exceeds a ‘limit’ or a full

‘alarm’ value.

Settings can be

optionally saved or

loaded from file.

This may be useful if you have made settings for particular engine types you frequently test.

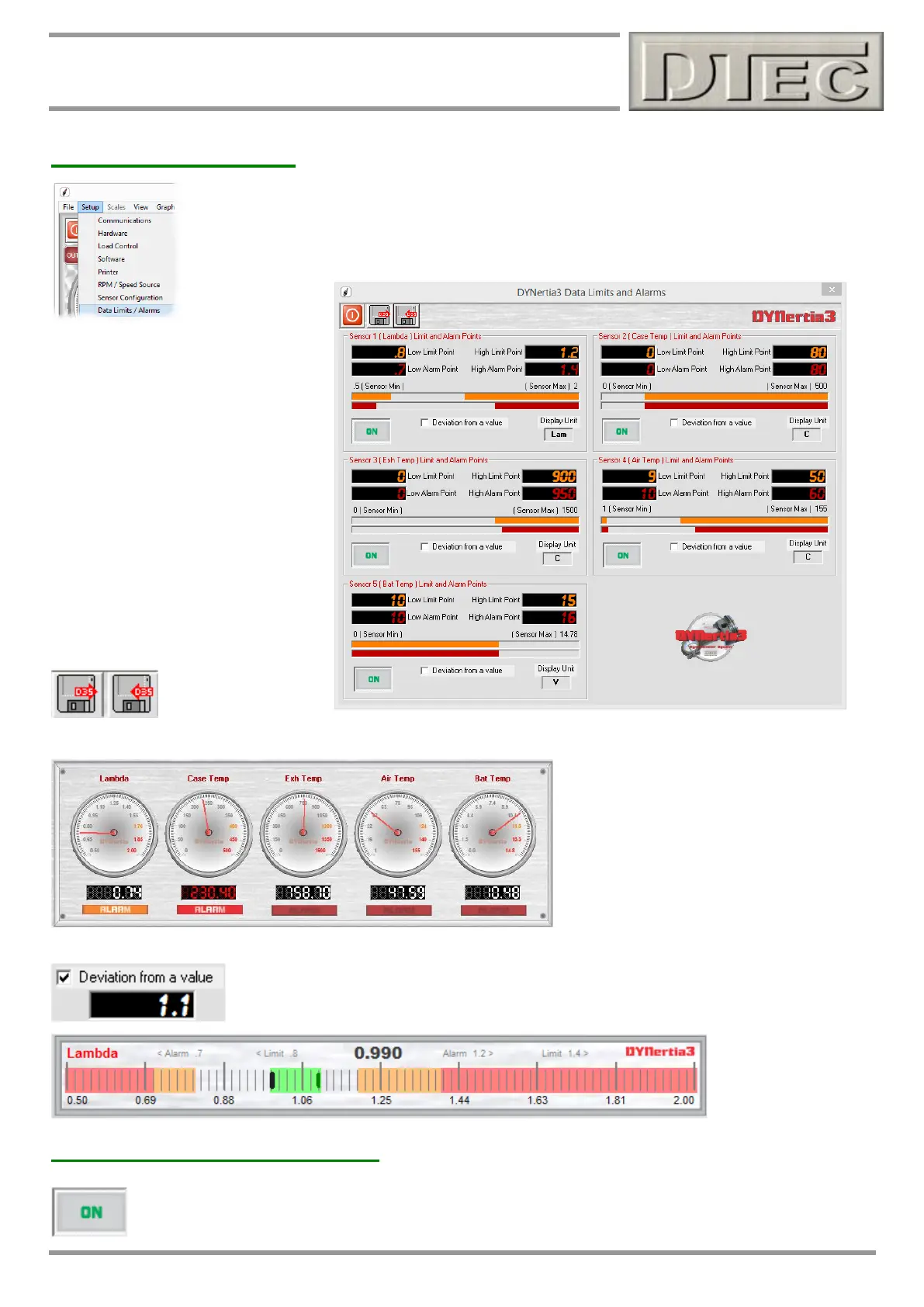

The Alarm lamps here are shown in all 3

states-

Lambda has exceeded ‘limit’ value.

Case Temp has exceeded alarm value.

Other data is within range.

Setting a deviation value changes the way the bar graphs display in the “Tunning Gauges”

screen (only visible with dual monitors configured). It places a marker at the value entered

and the band shows the value as it moves either side of the marker, as oppose to the band

starting from the Left hand side.

Sensor On / Off (Recording)

This option in ‘Sensor Configuration’ allows the data acquisition channels to be easily turned on or off so as

they do not record when testing.

Loading...

Loading...