www.dtec.net.au

Chapter 20: Trouble Shooting & FAQ’s

Frequently Asked Questions (FAQ’s)

The answers to some commonly asked questions that may increase your understanding of DYNertia3 and your dyno.

Q- Do I need a tachometer connected to DYNertia3?

A- Not necessarily, engine dyno’s normally don’t require a tacho due to the known fixed drive ratio and for a chassis

dyno it only requires that the engine RPM be known temporarily for initial ‘teaching’ (any RPM point can be used). Also

‘Speed’ mode uses Speed (kph) rather than RPM as the graphs X-scale (unlike in ‘RPM’ mode); this can be done if it is

not practical to use a tacho even temporarily.

There is an optional secondary tacho input in DYNertia3; this can be used as the sole RPM source and is useful for

determining clutch slip (engagement RPM) or loss of tyre traction. It can also allow automatic determination of the drive

ratio between the dyno and engine for quick ‘ratio teaching’ (see ‘RPM Input options’ chapter in this manual)

Q- How can it get engine RPM without ignition connections (I don’t have an ‘RPM adapter’ to connect to DYNertia3)?

A- DYNertia3 can determine the engine RPM from dyno flywheel RPM by ‘learning’ their relationship (ratio). Any

application that has a tacho already fitted, or can have one connected temporarily is particularly applicable. Many

vehicles tested on chassis dyno’s incorporate one and there are also many cheap commercial units available. Typical

engine dyno’s where the gear ratio is obvious (sprocket sizes known or direct drive) do not need a tacho (manually enter

the ratio).

Q- Why do Power levels seem to vary if I choose a

different gear or why do they seem to differ from what I

expect to see when I run an engine with considerably

different power ratings. Shouldn’t they be the same?

A- Any thing that alters the rate of acceleration of the

engine will alter the measured (not actual) Power. This is

due to the faster acceleration rate resulting in Power

being consumed in accelerating the engine components

(and wheels, chains, sprockets etc) themselves. Just as

on the race track in the ‘real world’.

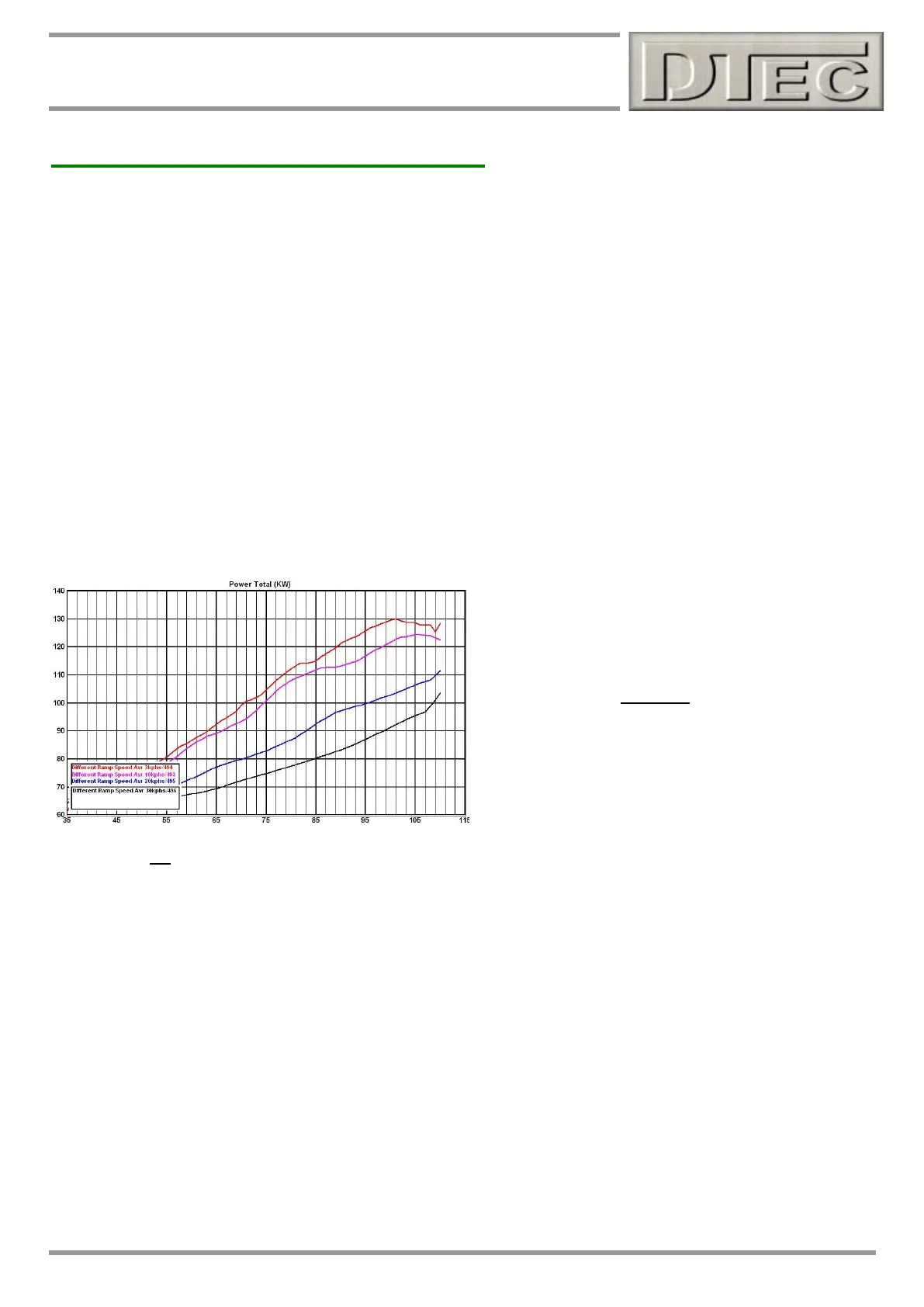

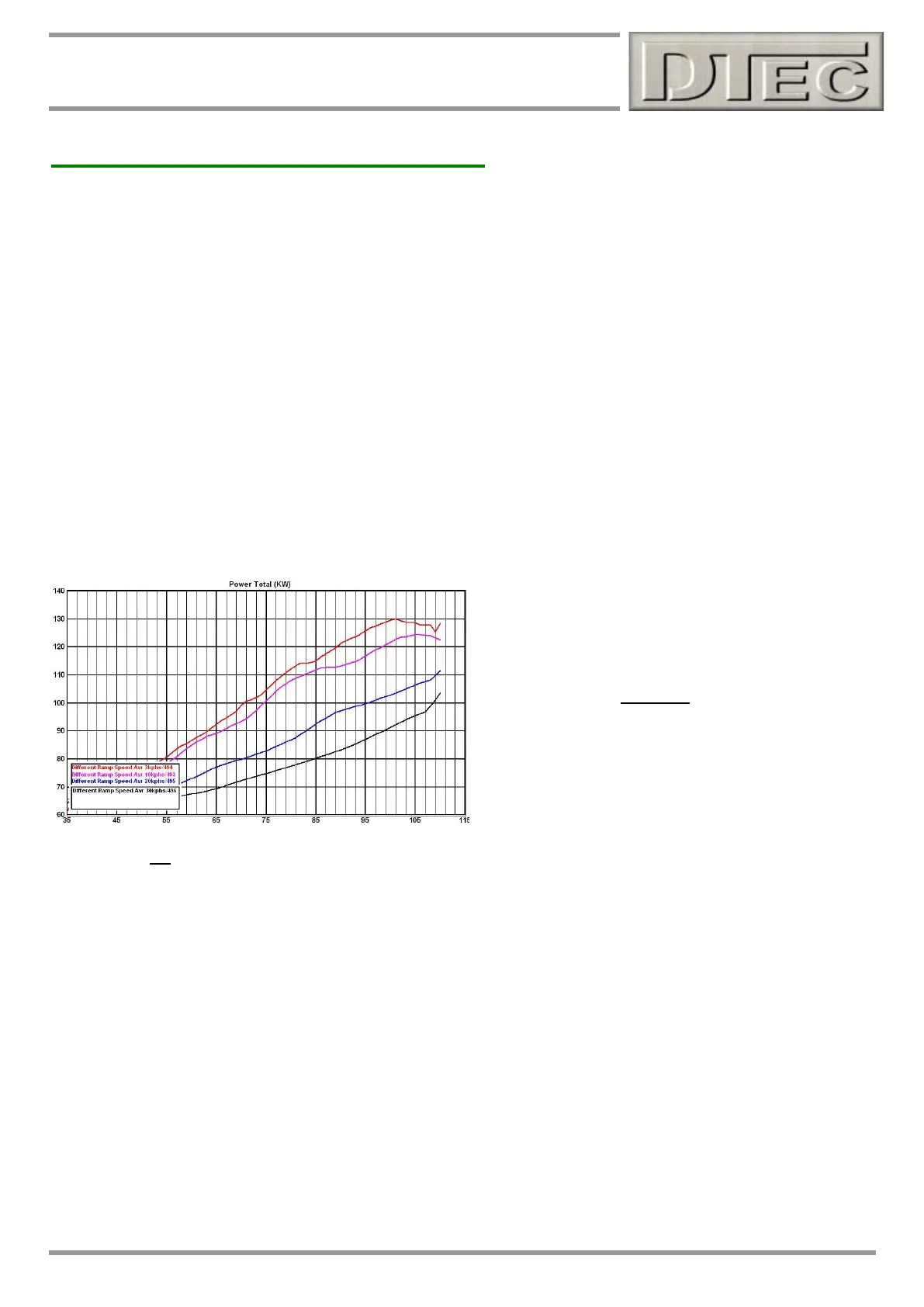

This graph shows the same vehicle ‘ramp’ tested at rates from 3, 10, 20 and 30 kph/sec. This is on a world class ‘eddy

current’ dyno, not even an inertia dyno. It shows the effect of engine/vehicle inertia clearly (faster = lower readings).

Unless true ‘step’ testing (requires ‘Brake’ style dyno) is used this effect always occurs. Inertia dyno’s give slightly lower

overall Power readings due to this acceleration. Also, manufacturers Power figures are often at the crank (no large

transmission loses, tyre loses etc), they are often optimistic (marketing department!) and some dyno’s add ‘fudge

factors’ that raise readings, this can all create an expectation of a certain power level!

Try and use inertia values and test gears that don’t allow the engine to accelerate too fast (please read the design guide

on www.DTec.net.au for full discussions), 8-10 seconds is generally considered suitable for a run depending on vehicle

/engine type (customers have built dyno’s that span from 2-20 second runs in practice and are happy with results!)

Q- My dyno doesn’t give the same figures as the one up the road. Is it accurate?

A- Accuracy is not really important, repeatability is! Take your vehicle to 6 different dyno’s and you’ll return with 6

different readings. This doesn't matter, what you need is repeatability so that if you put the vehicle back onto the same

dyno the figures are the same. Without this you can’t tune and are wasting your time! Inertia dyno’s are very, very,

repeatable! If your customer only wishes to see 'big numbers' and not necessarily 'better numbers' then he may as well

just travel around till he finds a high reading dyno (or the operator fiddles the correction factors) and not bother with

tuning! If the actual reading is a concern, consider your choice if inertia mass, test gear or the inertia value entered in the

setup screen or ‘losses’ correction.

Loading...

Loading...