www.dtec.net.au

Chapter 14: Inputs- Using

Data Consistency

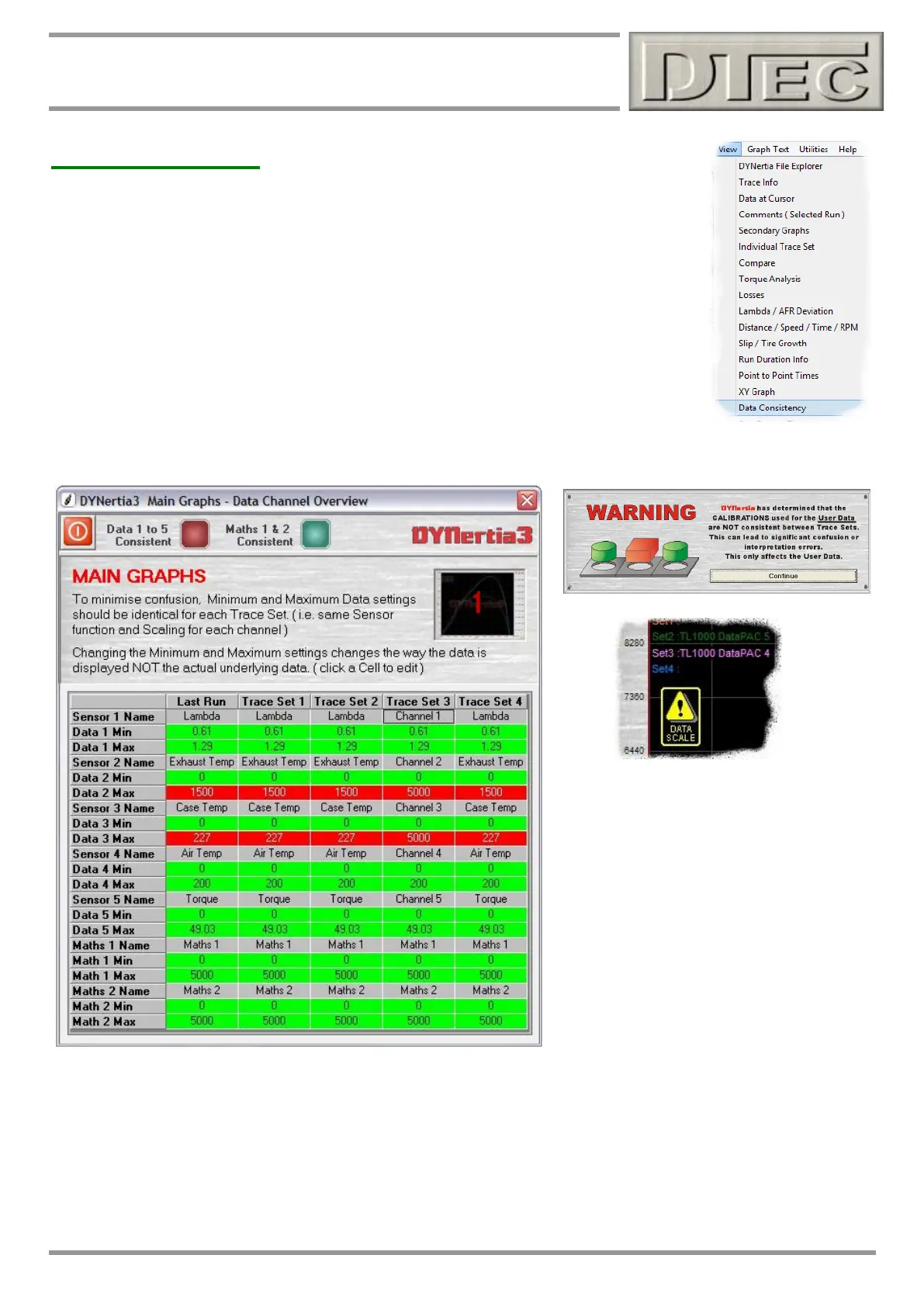

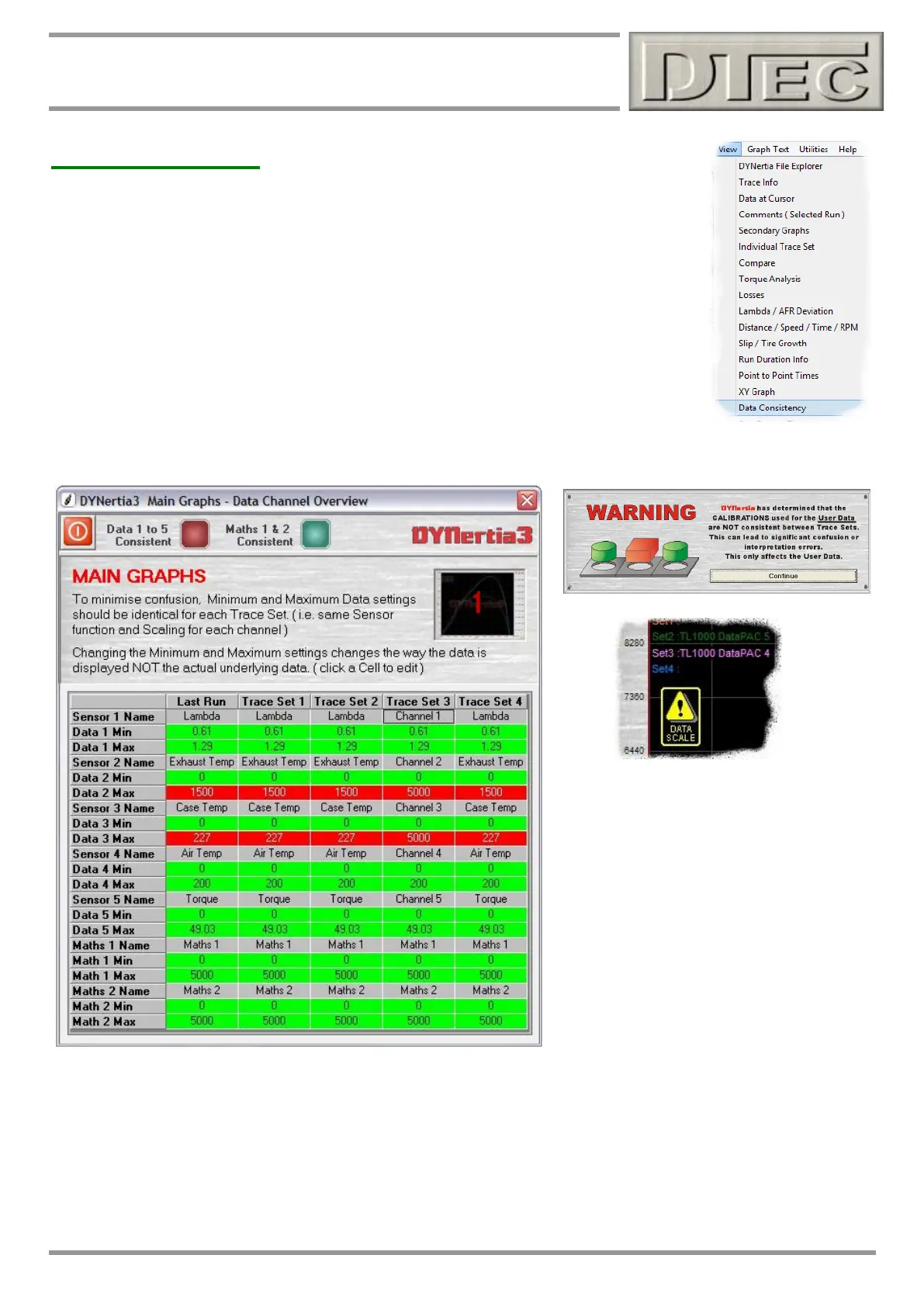

This Window shown below reveals an overview of the data channels and their scaling. If there

is an inconsistence detected between the calibrations from different selected Run traces then

it will be highlighted here as to which trace and channel has been recorded with a different

sensor calibration (compared to the lowest number trace).

For multiple overlaid traces to be meaningful then obviously they must all have been recorded

with the same calibrations applied. If you choose traces to compare that have been recorded

under different calibrations (i.e. if channel 1 is calibrated in Lambda for one test and

temperature for another test) then you will be warned and an icon will appear on the graph

screen to indicate this. If you view the overlaid data after being informed of the inconsistency

you must bear this in mind!

The extent of the warning can be altered in the menu option “Setup/Software/General", the two warnings are shown to

the right below.

The red boxes here indicate areas of data

inconsistencies, the scaling can be altered

here to align the values so when overlaying

they are consistent.

‘Clicking’ in the colour box’s allows you to

enter a new value and change the scaling

problem.

When inconsistent data is viewed, the scales actually shown to the Right of the main graph screen (CH1, CH2) will be

based on the trace set loaded into the lowest position (e.g. last trace recorded is highest priority, then trace 1, then 2 etc)

Tip- For consistency it is a good habit to use sensor calibrations that span the same range, for example if using

different coolant temp sensor types then calibrate them all from, say 0 - 200 degrees (regardless of type), that way when

data from the different tests is overlaid or merged it will still be valid!

Loading...

Loading...