7.10.8.1 Acknowledge automatically:

The pump switches to Pause on empty signal and the empty signal symbol is displayed in

red . The suction pipe issues a “Full” signal to the pump after a container change and

the container change is detected and accepted without further confirmation.

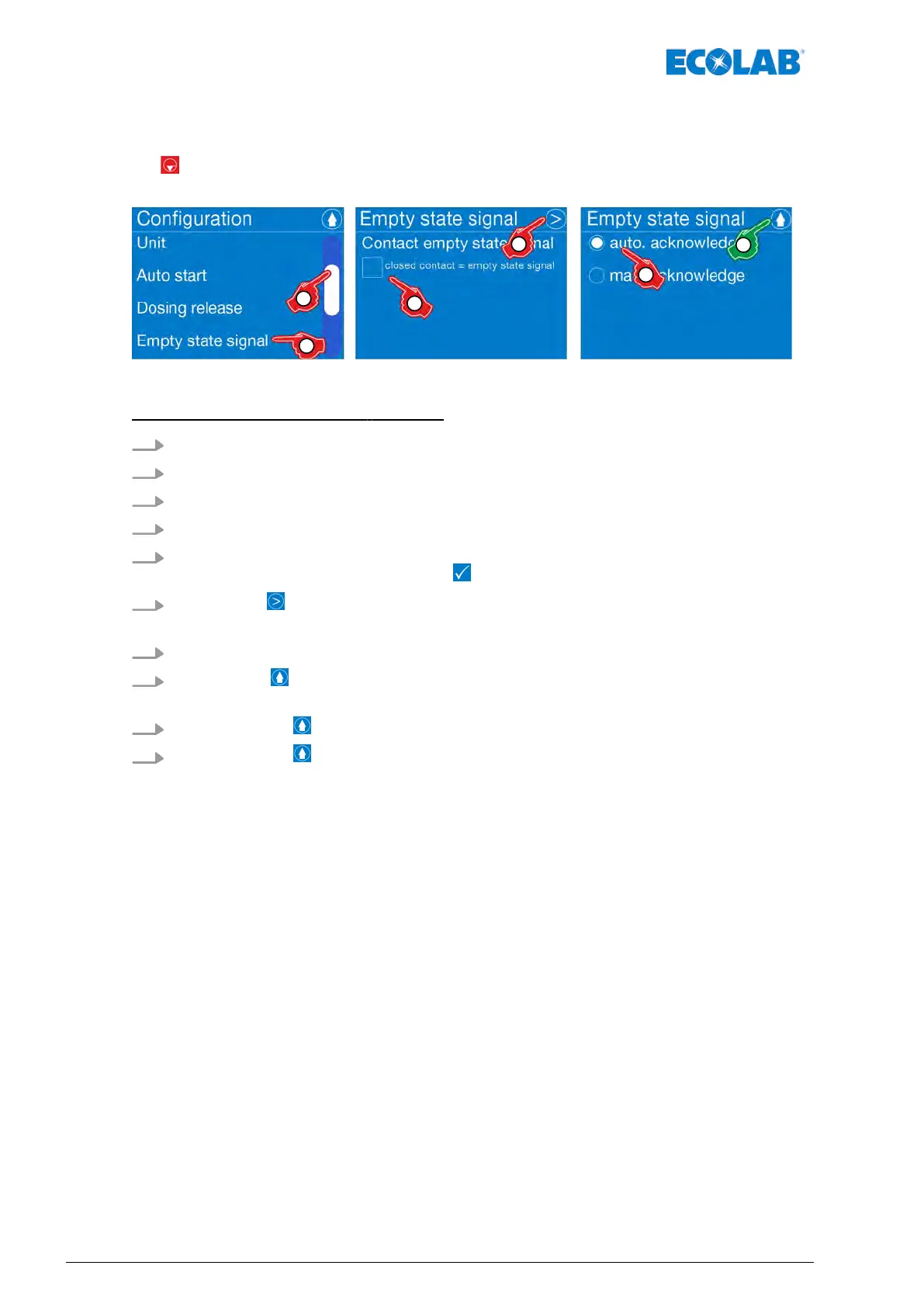

Fig. 56: Acknowledge automatically

[Acknowledge automatically] - setting:

1.

[Call up the Main menu] :

Ä

Chapter 7.7 ‘Main menu’ on page 73

2.

[Configuration] - setting:

Ä

Chapter 7.10 ‘Overview - Configuration’ on page 92

3. Use the scrollbar to scroll to the [Empty signal] .

4. [Select Empty signal]

.

5. If required, select ‘

Empty signal contact’: ‘Closed contact = Empty signal’ .

ð

After selecting this, a check mark

is set in the selection field.

6.

[ Click Next] to save the setting.

ð

Screen changes to the acknowledgement query of the ‘

empty signal’.

7. [Acknowledge automatically] .

8.

Pressing the button saves the setting.

ð

The screen switches to the overview: [Configuration].

9.

By pressing the button, you can return to the [main menu].

10.

By pressing the button, you can return to the [operating display].

Control / Software

104417102276 Rev. 5-02.2020

Loading...

Loading...