Maintenance 5. Actuator Units

N6 Rev.2 269

Installation

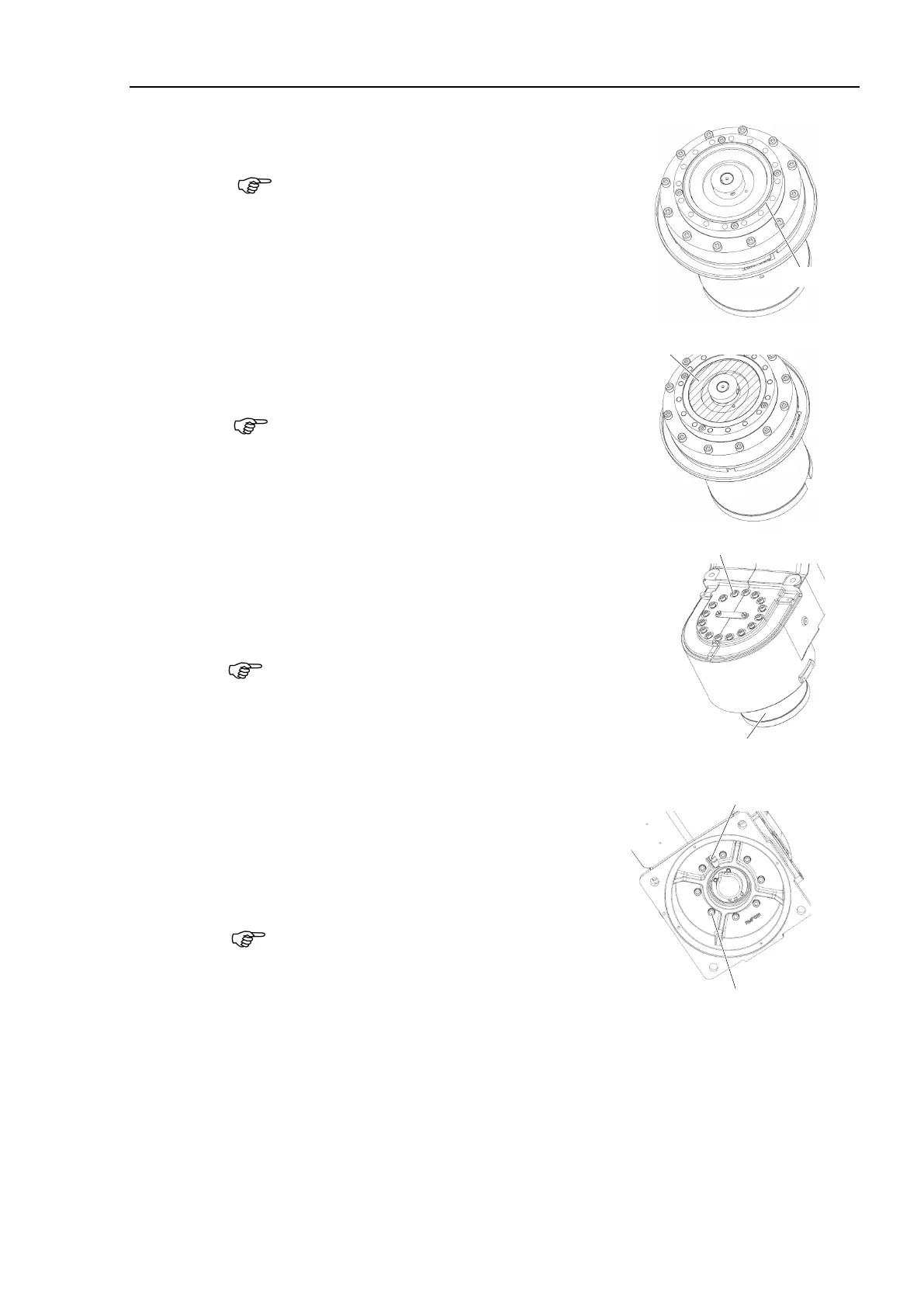

the attached O-ring to the

Apply a thin coat of grease to the O

-ring.

Grease: SK-1A

Joint #1

Actuator Unit

N6-A1000*

Cable direction:

Standard

(backward)

Apply the grease to the Joint #1 actuator unit.

Grease: SK-1A 15g

Be careful not to leak the grease from the

shaded area

shown in the right.

Install the Joint #1 actuator unit to the Arm #1.

Hexagon socket head cap bolts:

16-M5×35 (with plain washer)

Tightening torque: 10 ± 0.5 N·m

Be sure to have at least 2 people to perform the

operation since the parts being heavy.

Do not apply excessive shock to the parts.

-ring properly.

16-M5×35 (with plain washer)

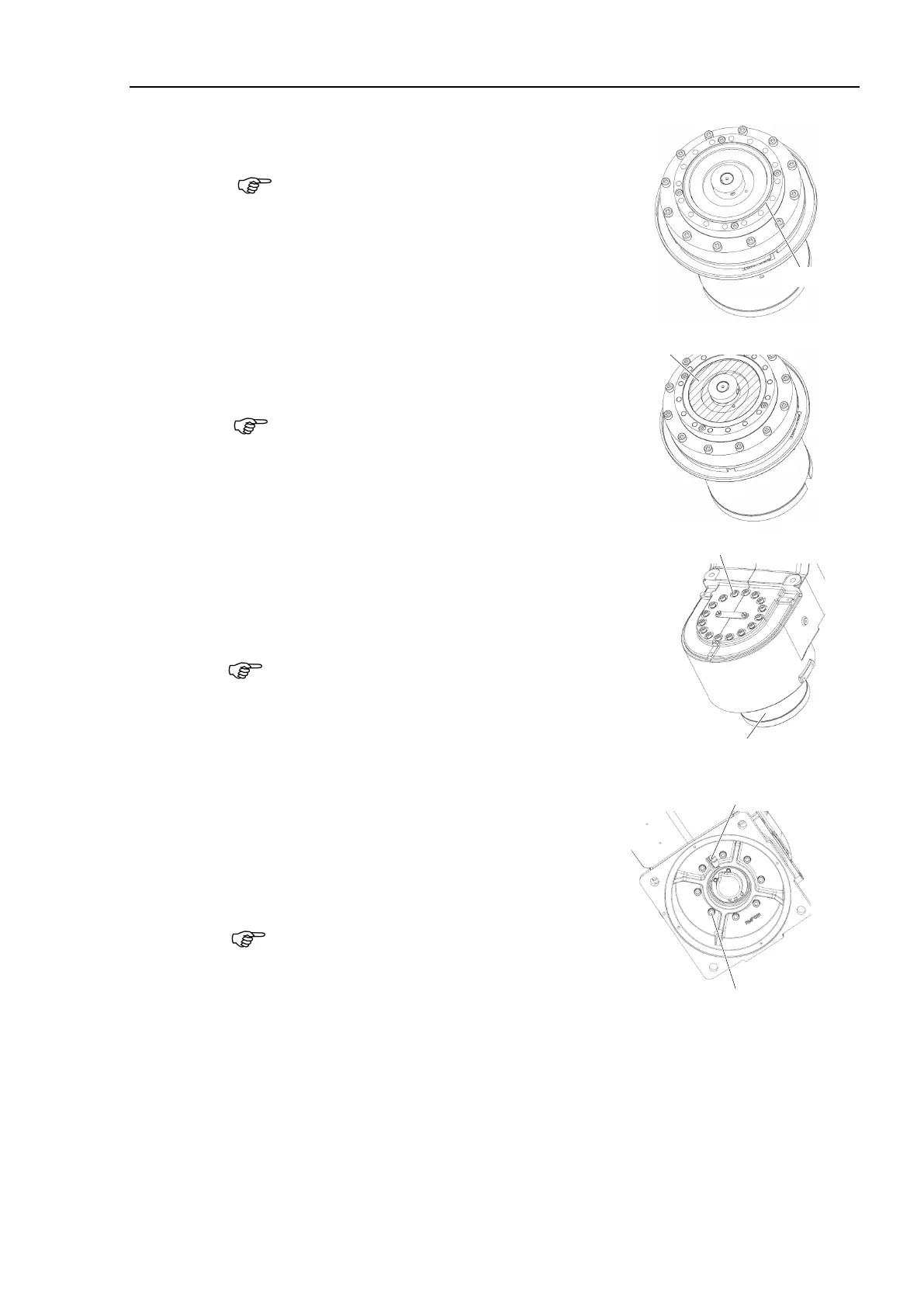

4)

Hexagon socket head cap bolts:

8-M6×40 (with plain washer)

Tightening torque: 18 ± 0.9 N·m

When installing it, make sure to align the

directions of the hole of the base and the cable

exit of Joint #1 actuator unit.

ass the cables of the Joint #1 actuator unit

the base.

catch the cables.

8-M6×40 (with plain washer)

Loading...

Loading...