Maintenance 5. Actuator Units

N6 Rev.2 301

Installation

Joint #5

Motor Unit

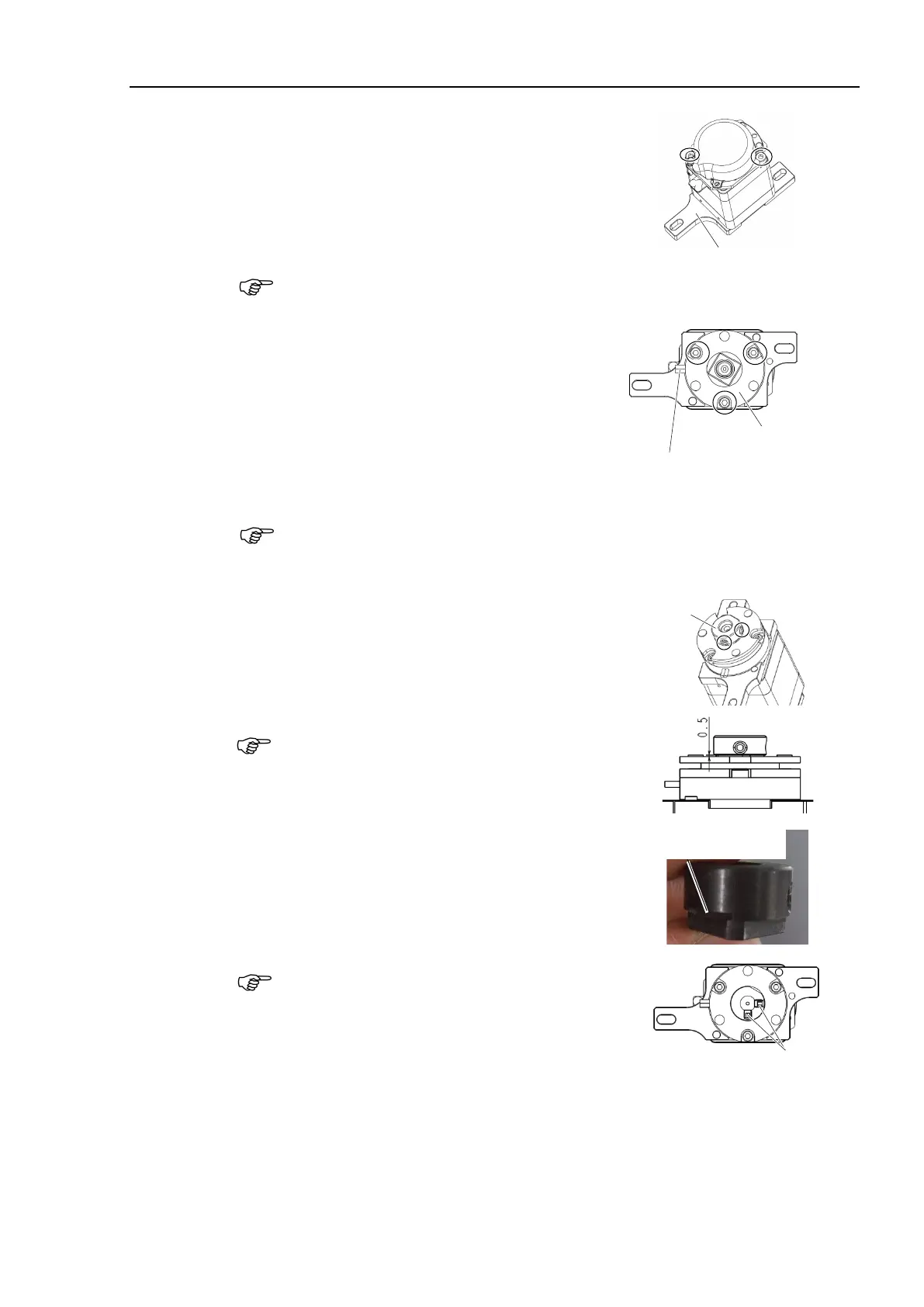

(1)

Install the motor plate on the Joint #5 motor.

Hexagon socket head cap bolts: 2-M4×55

Tightening torque: 4.0 ± 0.2 N·m

Be careful of the installation direction of the motor plate.

Refer to the figure and

it in the proper position.

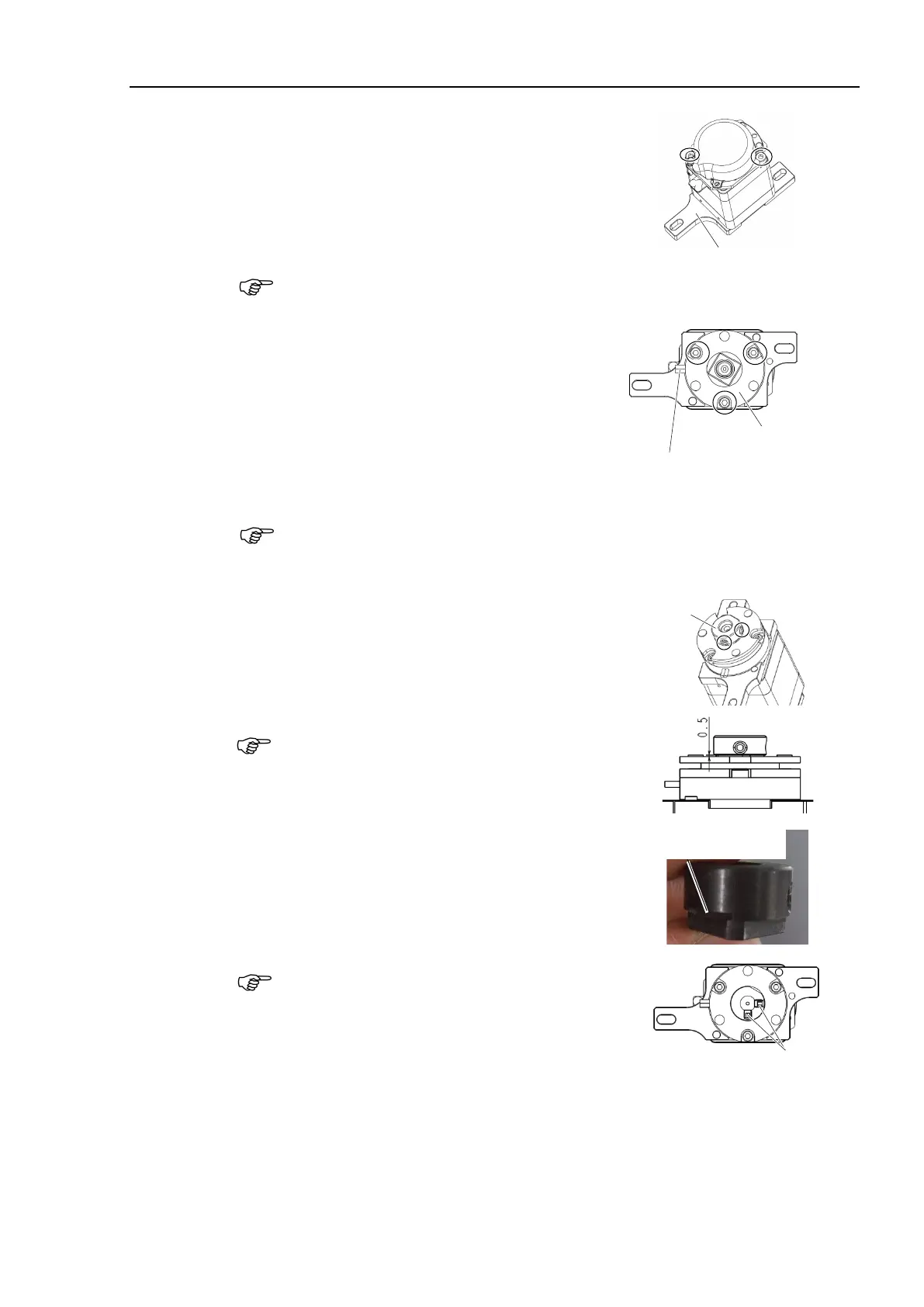

(2)

Install the Joint #5 electromagnetic brake on the

Joint #5 motor unit.

Install the spacer between

the hexagon socket head cap bolts and the Joint

#5 electromagnetic brake.

Hexagon socket head cap bolts: 3-M3×13

Tightening torque: 2.0 ± 0.1 N·m

Cables of

Electromagnetic brake

Direction to exit the cables of th

e electromagnetic brake is set.

Install the electromagnetic brake so that the cables of the electromagnetic brake

are

positioned in the same direction as the motor cables.

(3)

drive bosses on the motor shaft on

Hexagon socket set screws: 2-M4×4

Tightening torque: 2.4 ± 0.1 N·m

When fixing the drive bosses, make sure that the

clearance

between the drive bosses and the

brake will be 0.5mm.

feeler gauge (0.5 mm) of the drive boss to

(0.5 mm).

Cutout

Place in 90 degrees

aligned with the D-cut

surface on the motor shaft.

If the screw

positions are not correct, the side of part will get

damage and you cannot

pull out the part.

Hexagon socket set screws

Loading...

Loading...