Maintenance 5. Actuator Units

302 N6 Rev.2

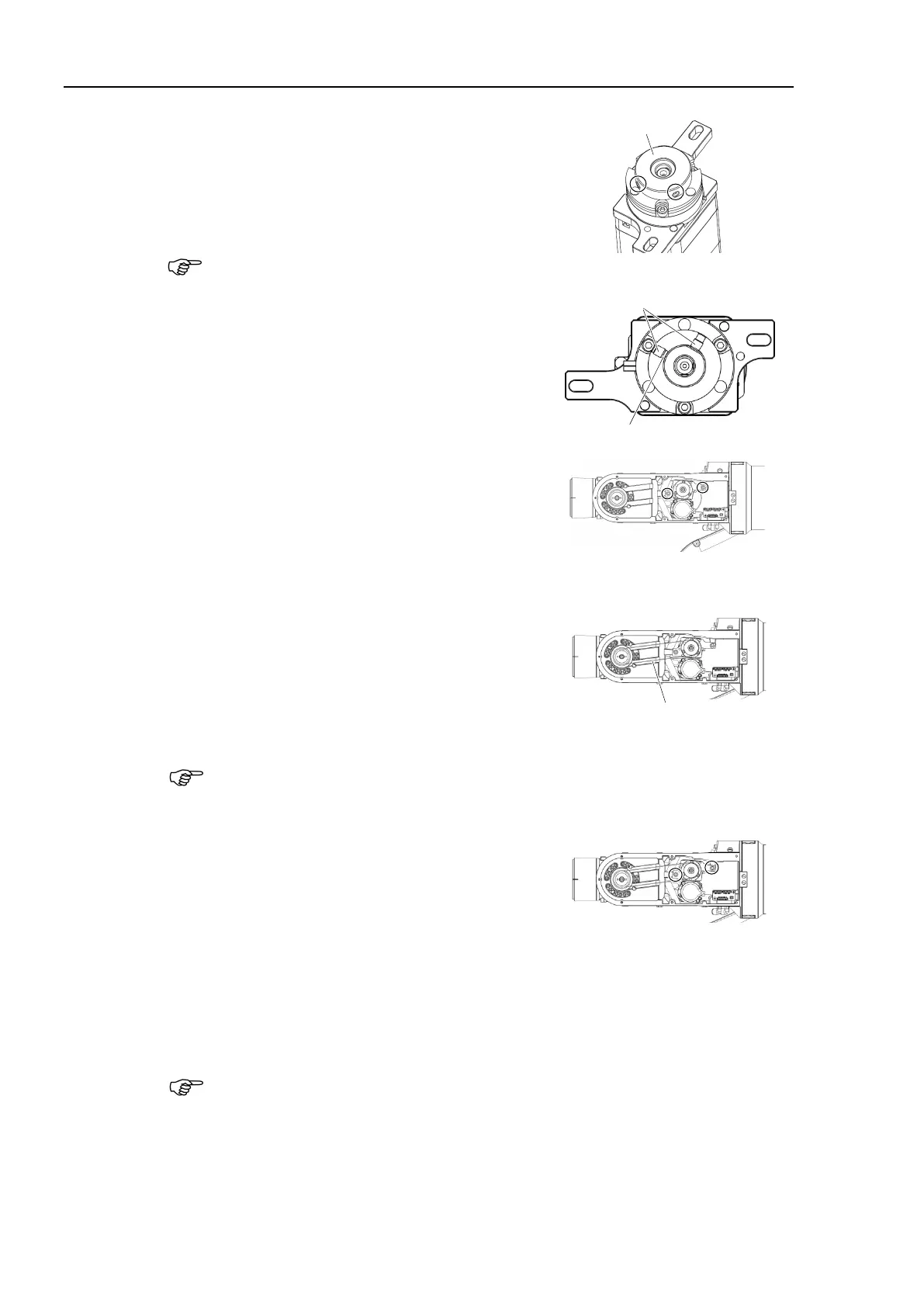

(4)

Install the pulley on the drive boss.

Hexagon socket set screws:

2-M4×4 (brass bushing × 1)

Tightening torque: 2.4 ± 0.1 N·m

Push the pulley to the drive boss and fix it.

Fix the set screw to align with the D

-cut

surface. Fix the other one after installing the

bushing.

If the screw positions are not correct

or you forget to install the bushing, the side of

part will get damage and

you cannot pull out

Hexagon socket set screws

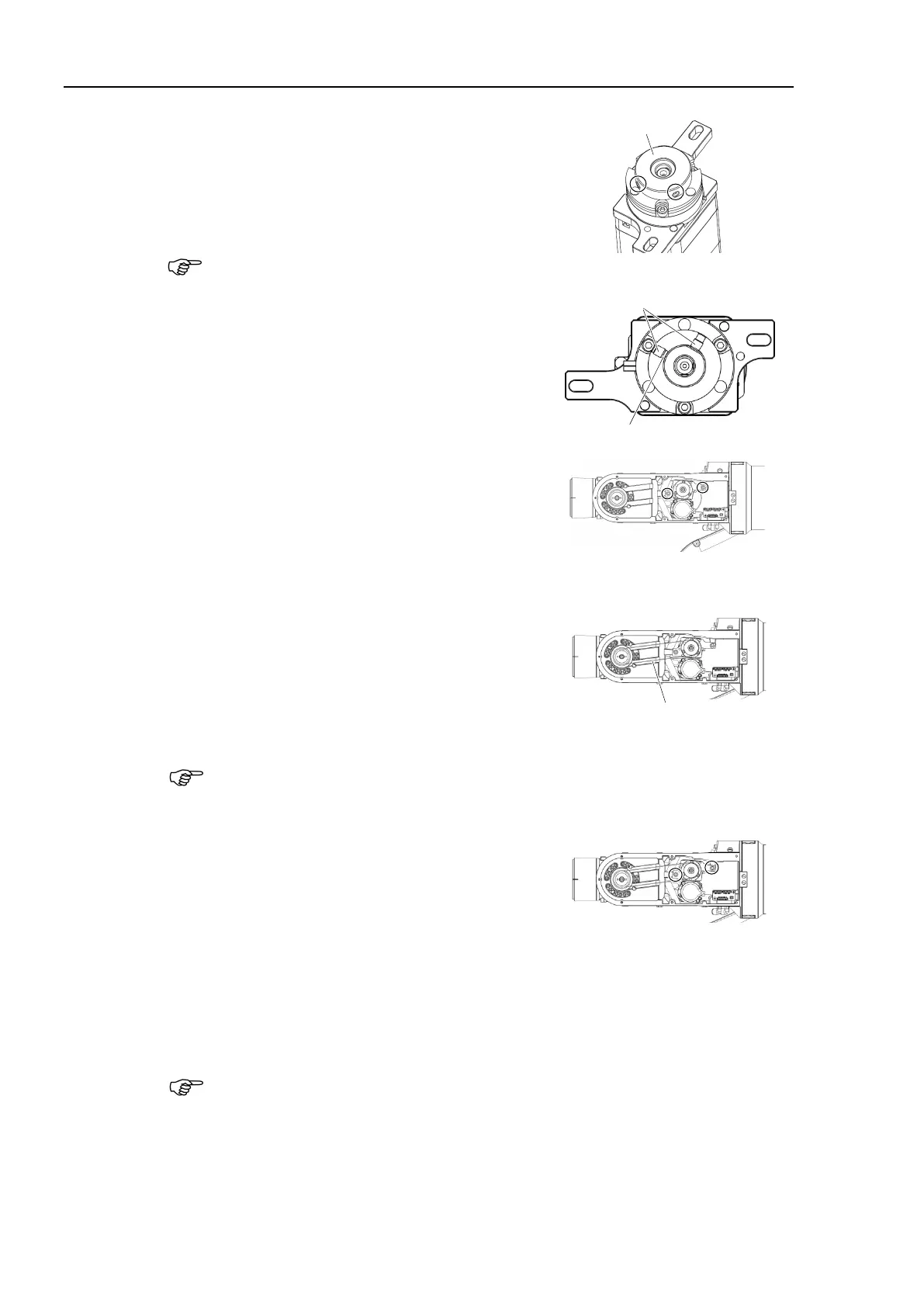

(5)

Install the Joint #5 motor unit on the Arm #4.

Hexagon socket head cap bolts: 2-M4×15

(with plain washer for slotted hole

thickness: 1.5mm)

Do not tighten the screws completely. Loosen

them so that the motor unit will

not fall.

(6)

Install the timing belt and temporarily fix the

Joint #5 motor unit.

Hexagon socket head cap bolts: 2-M4×15

(with plain washer for slotted hole

thickness: 1.5mm)

When temporary fixing the Joint #5 motor unit, make sure that the motor unit can be

moved by hand and does not tilt when being pulled. If the unit is fixed too loose or too

tight, the belt will not have proper tension.

(7)

Apply the proper tension to

the Joint #5 timing

belt and fix the Joint #5 motor unit.

Tension of Joint #5 timing belt: 23 ± 5 N

Belt tension meter setting value

Weight: 2.5g/mm Width×m Span, Width:6 mm, Span:142 mm

Hexagon socket head cap bolts:

2-M4×15 (with plain washer for slotted hole thickness: 1.5mm)

Tightening torque: 4.0 ± 0.2 N·m

Regarding belt tension:

- Jumping (position gap) may occur if the value is below the lower limit.

- Vibration (abnormal noise) or reduction of life of the parts may occur if the

value exceeds the upper limit.

Loading...

Loading...