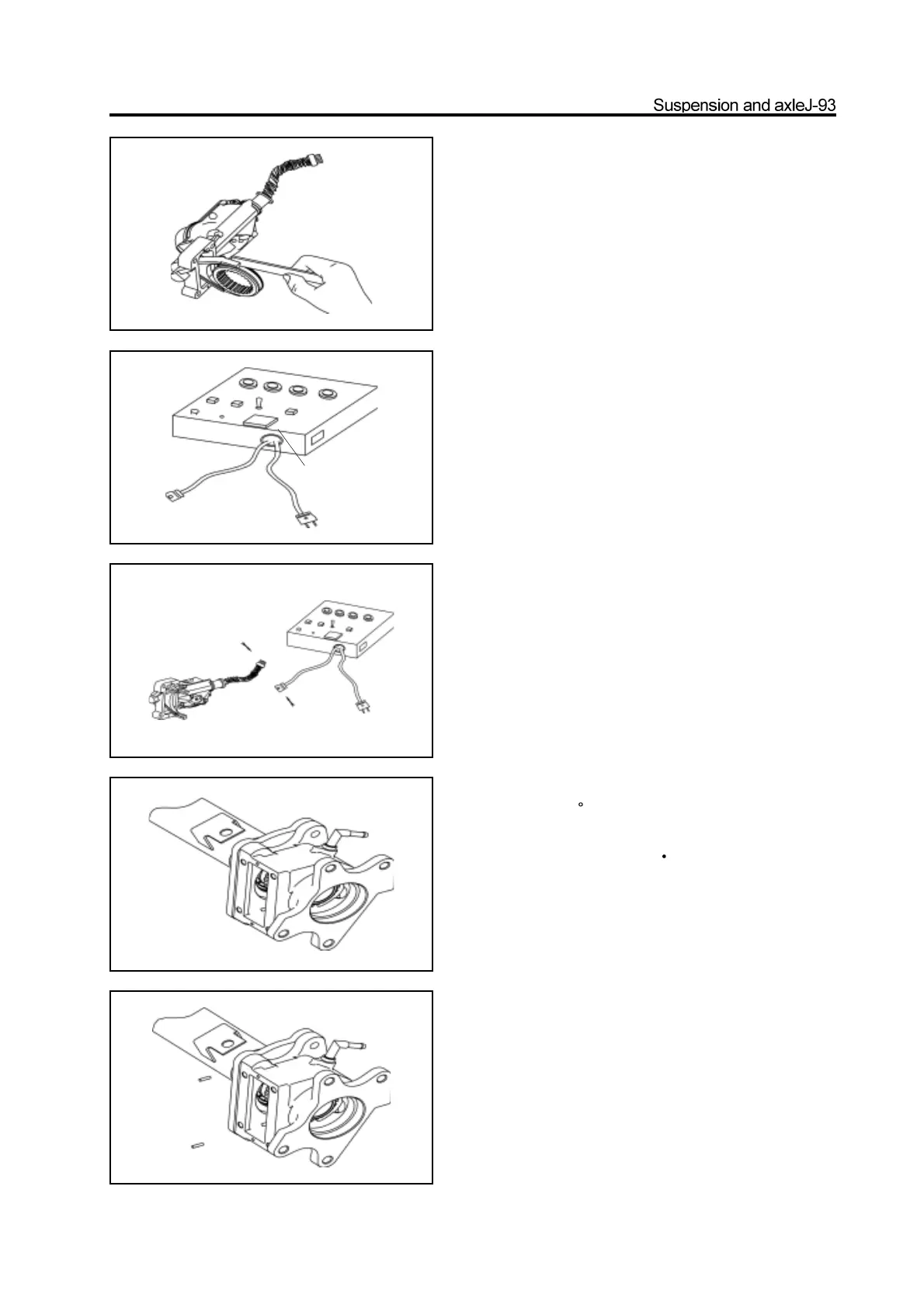

electric clutch detector

37. Detect the electric clutch assembly .

a. Measure the clearance between the shift fork and shift fork

sleeve.

Range of clearance : 0.2-0.4mm

It should replace the electric clutch assembly and shift fork

sleeve when the clearance is not in the range.

b. Connect the electric clutch assembly to the electric clutch

detector and power the electric clutch detector with 220V

power supply to test the electric clutch (Before the test,

adjustthe test controller status to make the motor starting time

is 3s ,the time form found the actuator is not in position to

restartingis 2.5s and the time of controller to redrive the

electric clutch is2s) The motor starts for 3s when the gear

switch is shifted form 2WD to 4WD, the lamp flashes at the

same time, the clutch is in 4WD status, the indicator lamp is

light always. If does not reach the 4WD status in the first

time, then the controller restarts it for 2s after 2.5s delay, the

lamp flashes at the same time; if it is still not in position, then

the indicator lamp flashes twice continuously, the indicator

lamp is extinguished for 1s, the motor is stopped. That means

the electric clutch is unqualified and should be replaced by the

qualified product. The motor starts for 3s normally when the

clutch is shifted form 4WD to 2WD, the lamp flashes at the

same time, when the clutch is in 2WD status, the indicator

lamp is extinguished always. If does not reach the 2WD status

in the first time, then the controller restarts it for 2s after 2.5s

delay, the lamp flashes at the same time; if it is still not in

2WD status, then the indicator lamp flashes twice

continuously, the indicator lamp is extinguished for 1s, the

motor is stopped.

That means the electric clutch is unqualified and should be

replaced by the qualified product.

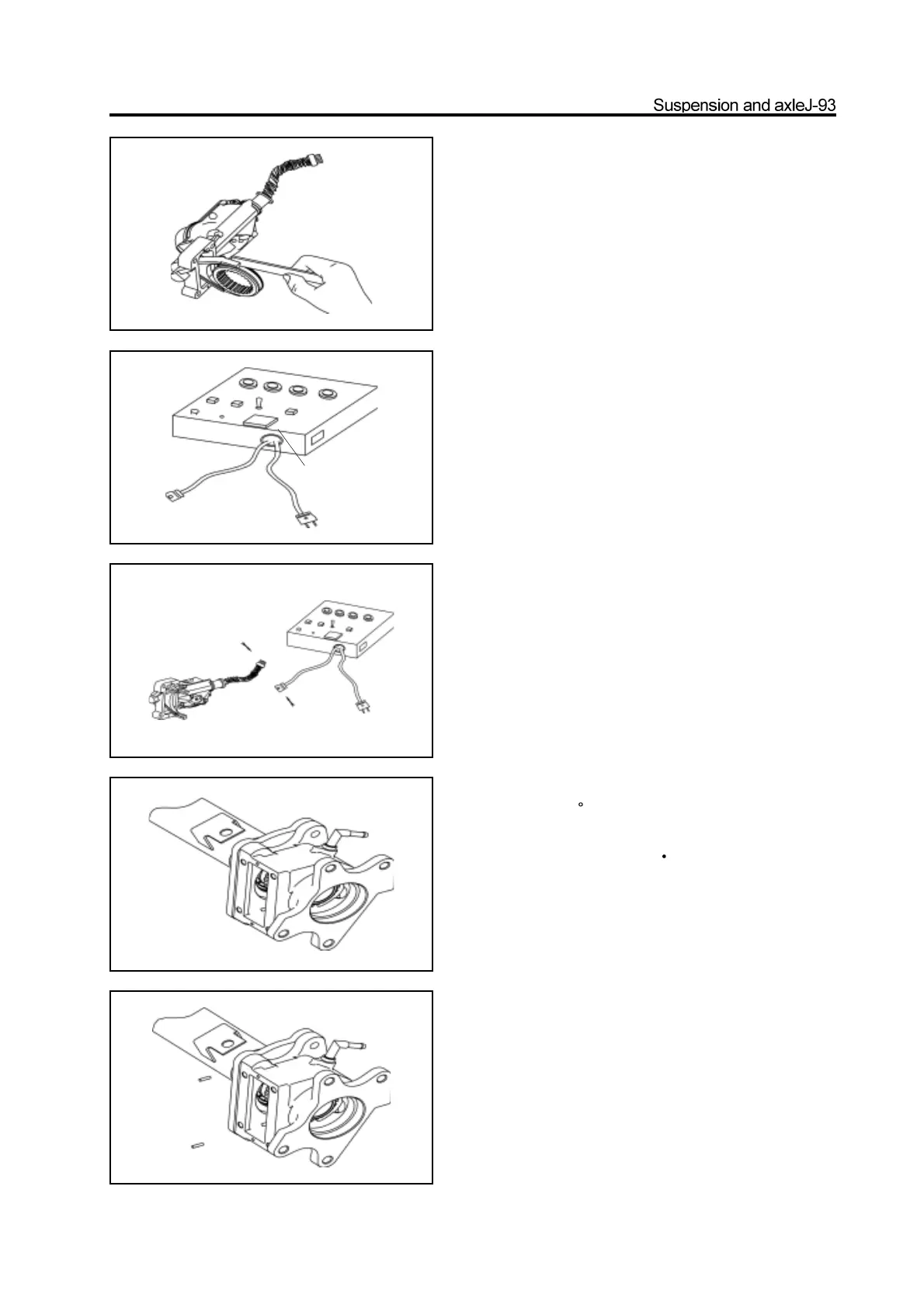

38. Cover the shift fork sleeve on the major

semiaxle spline.

39. Install the separator housing on the front axle

tube flange and use the bolt to tighten it to the

specified torque

(The bolt should be precoated

with the screw lock agent and the amount should be

just can cover the complete screw)

specified torque : 90-110N m

Caution: Before installation, remove the foreign material on

two matching surfaces of separator housing and front axle

tube flange; and precoat the 1596 silicon rubber plane sealant

on the front axle tube flange. Caution: Prevent the sealant

from entering into the screw hole.

40. Press in the plastic vent tube on the electric

clutch housing and front axle tube.

41. Install two location pins in the location pin hole

of electric clutch housing respectively.

42. Coat the connecting surface of electric clutch

housing and electric clutch with 1596 silicon rubber

sealant uniformly; level it by plate.

Caution: The connecting surface should be cleaned

and must not have the oil and other foreign

matters. The sealant must not enter into the elec-

tric clutch housing and screw hole.

Loading...

Loading...