2 - 88 Conversational Part Programming v546CO WinMax Lathe Conversational Part Programming

• X’ CENTER—defines the X location of the blend arc’s center point. This read-

only field is carried forward from the previous segment and can only be

edited in that screen.

• Y’ CENTER—defines the Y location of the blend arc’s center point. The Y’ axis

will be wrapped on the cylinder diameter. This read-only field is carried

forward from the previous segment and can only be edited in that screen.

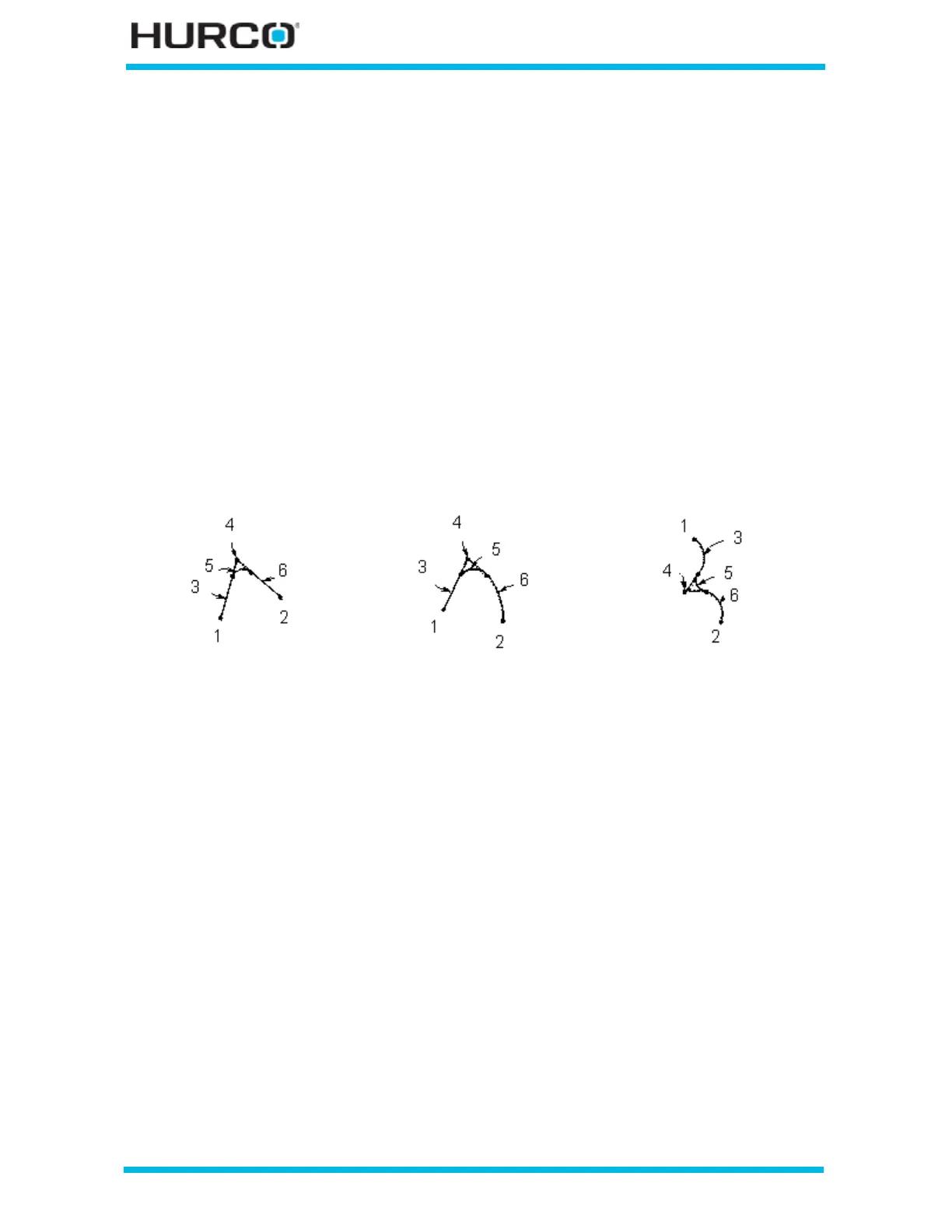

A blend arc joins two other segments and is tangent to both. A blend arc can be used to

join these types of segments:

•two Line segments.

• a Line segment and an Arc segment.

•two Arc segments.

The segments to be joined must have a theoretical point of intersection. If the only

information known about an arc is its radius, it is easier to program it as a blend arc (if

the segments intersect). The diagram below illustrates some examples of blend arcs.

Figure 2–76. Blend Arc Examples

Some guidelines that must be followed when creating a blend arc follow:

• The first or last segment of a Radial Mill Contour data block cannot be blend

arc segments.

• Blend arc segments cannot be adjacent to one another in a program. For

example, if segment #2 is a blend arc, neither segment #1 nor #3 can be

blend arc segments.

Two Lines joined by a

Blend Arc

Line and Arc Joined by a

Blend Arc

Two Arcs Joined by a

Blend Arc

1 X/Y Start

2 X/Y End

3 Segment 1 (Line)

4 Segment 1 End/

Segment 3 Start

(Point of Intersection)

5 Segment 2 (Blend Arc)

6 Segment 3 (Line)

1 X /Y Start

2 X/Y End

3 Segment 1 (Line)

4 Segment 1 End/

Segment 3 Start

(Point of Intersection)

5 Segment 2 (Blend Arc)

6 Segment 3 (Arc)

1 X/Y Start

2 X/Y End

3 Segment 1 (Arc)

4 Segment 1 End/

Segment 3 Start

(Point of Intersection)

5 Segment 2 (Blend Arc)

6 Segment 3 (Arc)

Loading...

Loading...