2 - 142 Conversational Part Programming v546CO WinMax Lathe Conversational Part Programming

• LINEAR Y MOTION—select this checkbox to cause Y-Axis Motion using the X

and X’ axes. When this checkbox is clear, Y-Axis Motion occurs using the X

and C axes. Please refer to Programming Coordinates and Linear Y Motion, on

page 2 - 68 for examples. This field is available with TMX MY and TMX MYS

series machines.

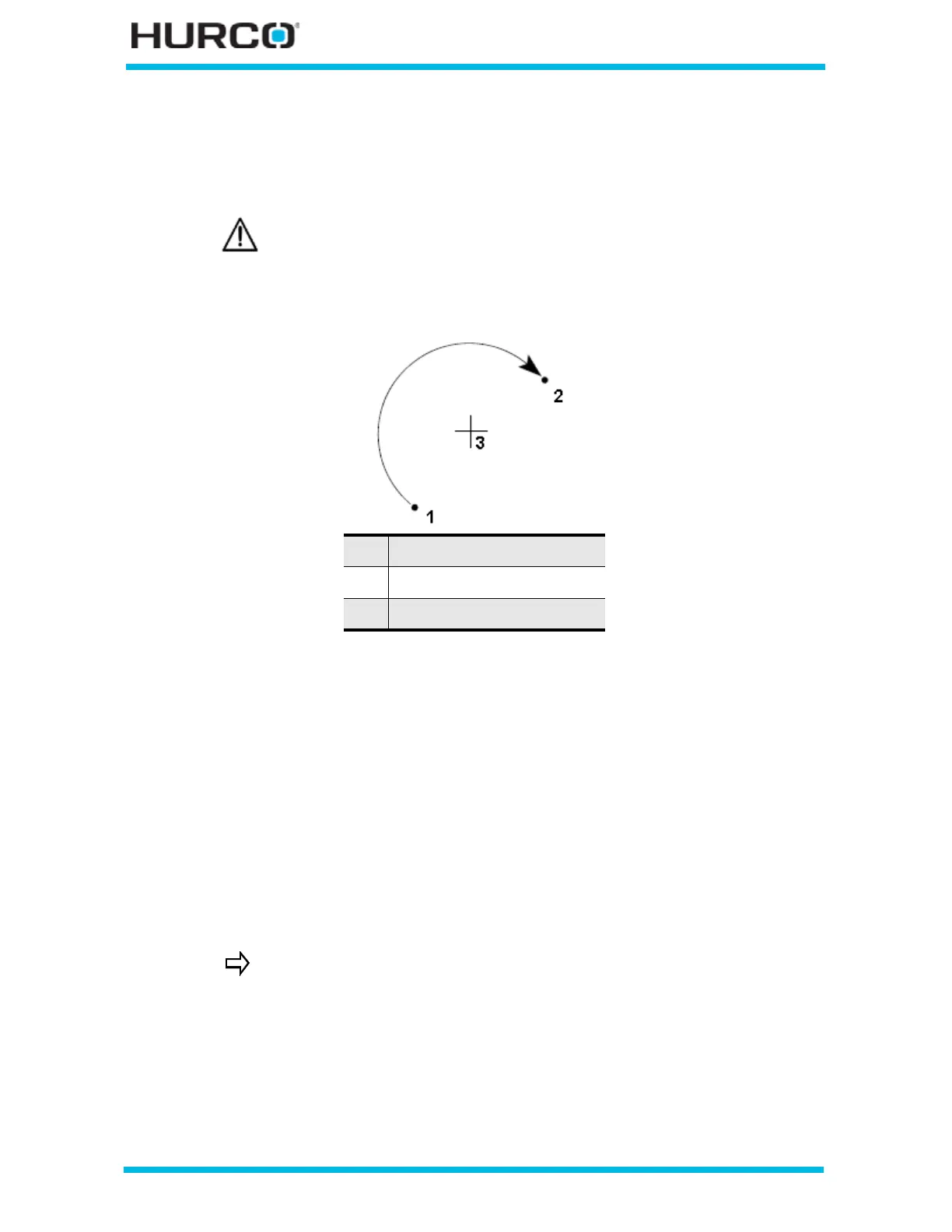

Examples of these coordinates for a clockwise arc are shown below:

Figure 2–119. Coordinates of a Clockwise Arc

The Calc-Assist feature calculates certain unknown arc segment dimensions

automatically, after sufficient data has been entered. A parameter with a calculated value

is indicated with “CAL” preceding the value.

• The values of center points plus start point or end point coordinates s are

used to calculate the arc radius.

• Start point and end point coordinates plus the radius are used to calculate

two possible center point coordinates.

• Either of the end point values and the center point coordinate supplies the

value of the other end point and the radius parameter.

• A known center point, start point, or end point and radius are used to

calculate an unknown center point coordinate.

Linear Y-Axis Motion is limited. The amount of Y travel is affected by

the X position and by any X-Axis tool length offset.

1 Start Point

2 End Point

3 Center Point

A series of arcs and lines can be programmed in a single data block

to form a complete contour. Press the Ctrl + arrow key to program

additional Line and Arc segments for the current data block.

Loading...

Loading...