Direct Fuel Injection

90-8M0050731 MAY 2011 Page 3B-77

Tube Ref No. Description Where Used Part No.

7

Loctite 271 Threadlocker Air compressor end cap screw threads 92-809819

Description Nm lb‑in. lb‑ft

Screw (carbon steel) (M6 x 20) 17 150

Screw (stainless steel) (M6 x 20) 11.5 100

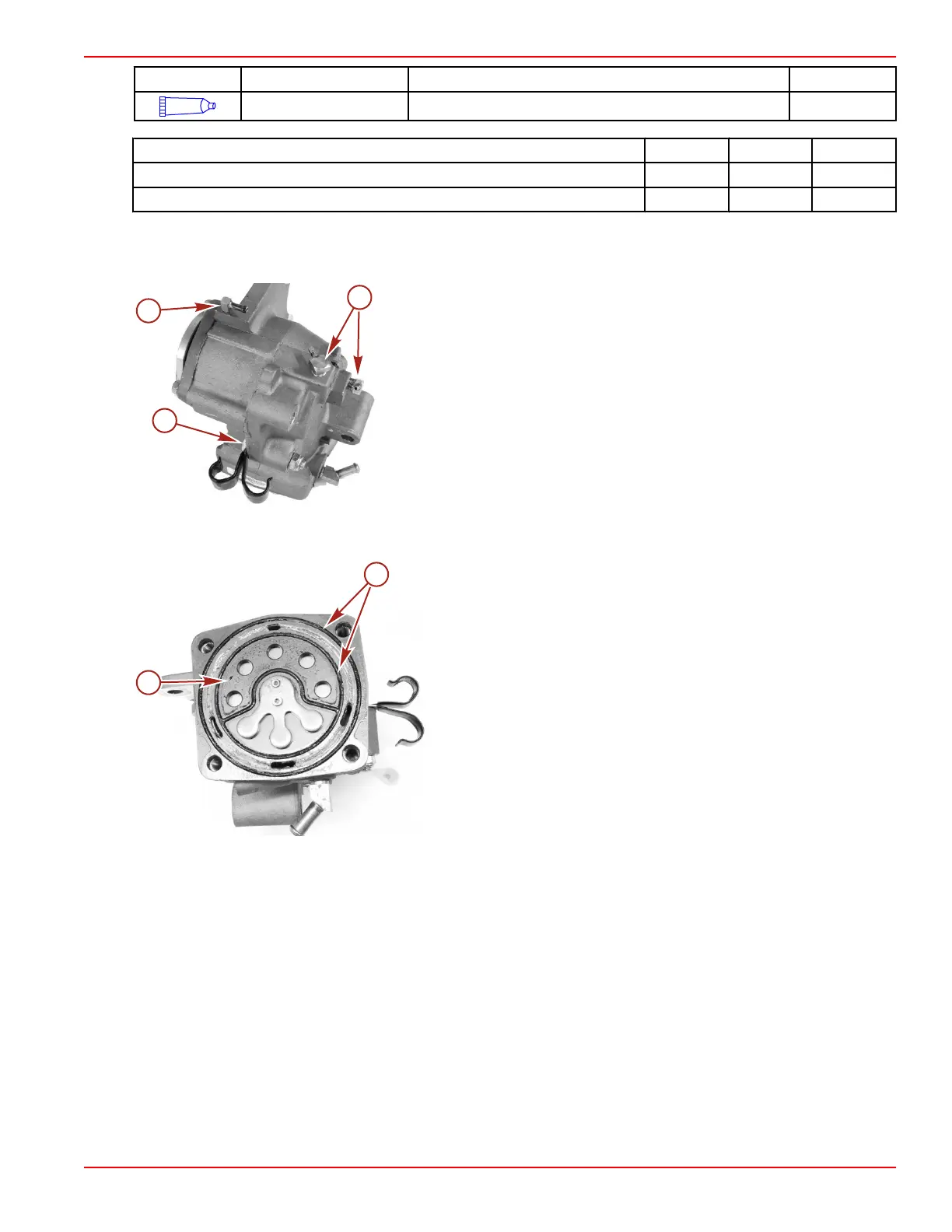

10. Install the two check valves onto the air compressor.

11. Install and secure the two J‑clamps, if used, to the air compressor with a bolt and nut. Tighten the bolt and nut securely.

NOTE: Later models will use either a plastic clip or cable ties in place of the two J‑clamps.

a - Bolt and nut securing the two J‑clamps

b - Oil supply fitting

c - Check valves (2)

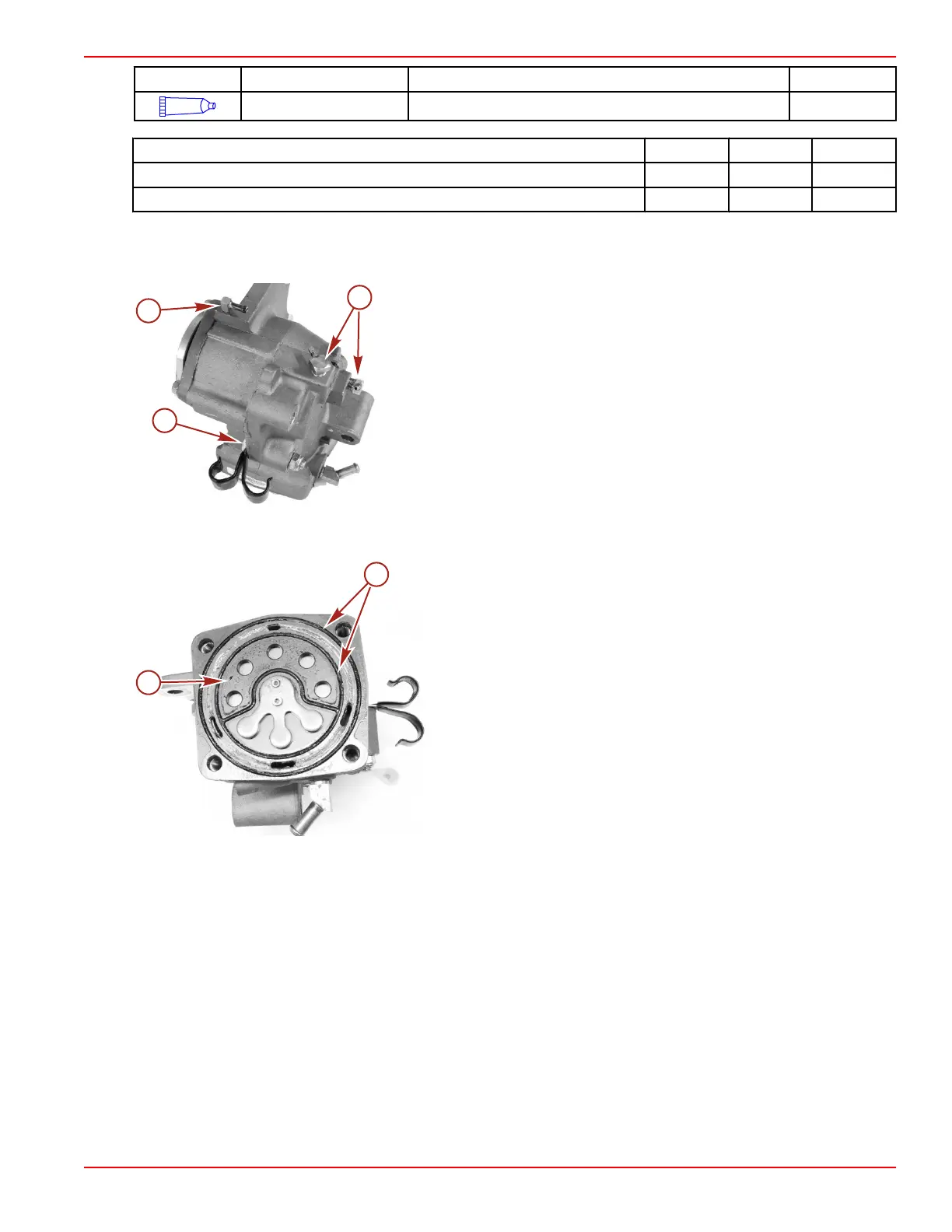

12. Install the O‑rings onto the reed plate assembly.

13. Install the reed plate assembly with the five petal side towards the piston.

a - Reed plate

b - O‑rings

14. Install the air compressor cylinder head and secure with four M8 x 35 screws. Tighten the screws to the specified torque.

15. Install the air compressor temperature sensor into the cylinder head.

Loading...

Loading...