Direct Fuel Injection

90-8M0050731 MAY 2011 Page 3B-79

3. Install the oil line coming from the oil pump onto the fitting under the air compressor pulley and secure with a cable tie.

a - Cable tie securing the oil line coming from #5 reed block

b - Cable tie securing the oil line coming from the top main

bearing

c - Cable tie securing the oil delivery line coming from the oil

pump

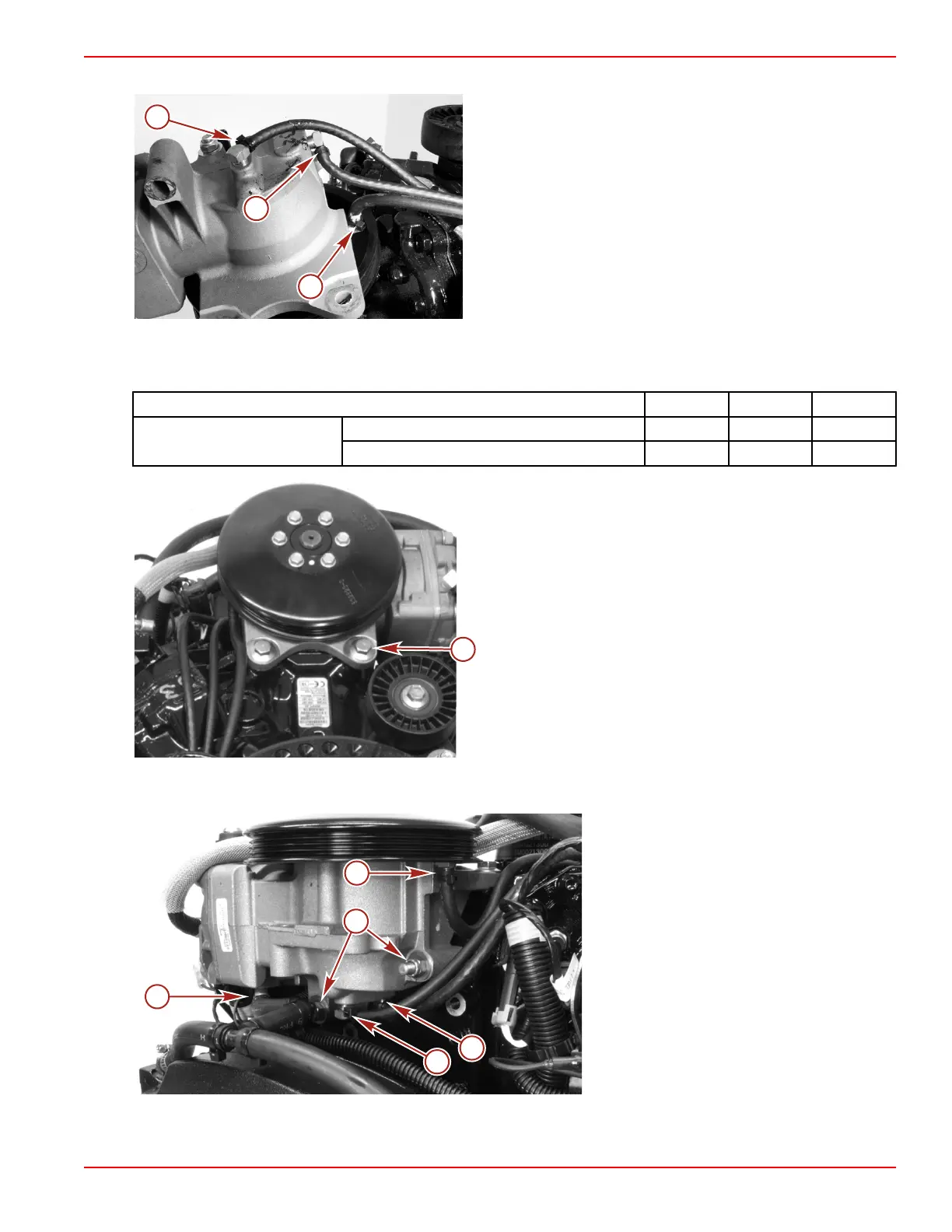

4. Install the air compressor onto the studs.

5. Install the two top screws (M10 x 25) finger‑tight and then tighten to the first specified torque.

IMPORTANT: Do not overtighten. This is the first of a two stage torque process.

Description Nm lb‑in. lb‑ft

Screw (M10 x 25) (2)

First 1.5 13

Final 56 41.3

a - Screw (M10 x 25, flange) (2)

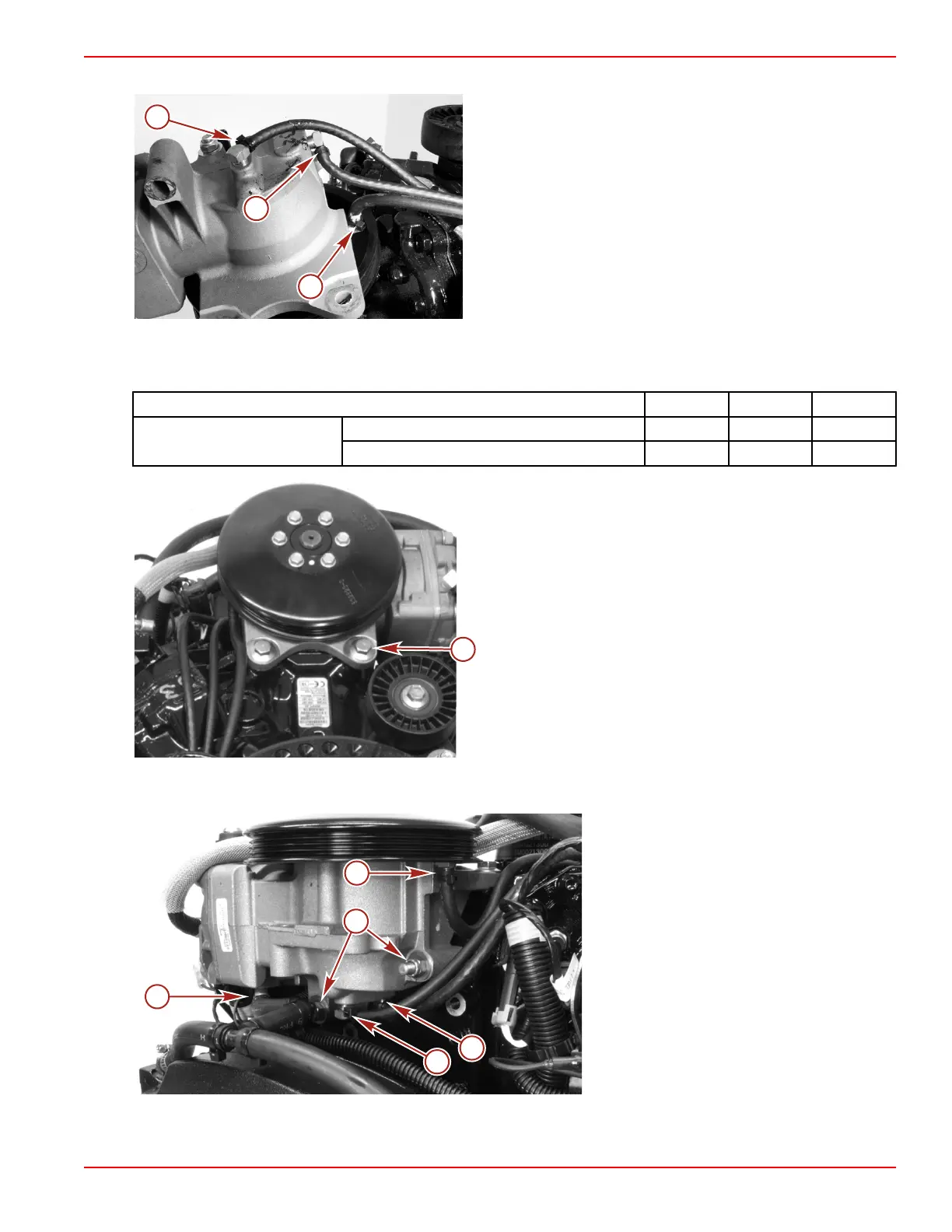

6. Install the water dump hose to the air compressor and secure with a cable tie.

7. Install a washer and nut onto each stud and tighten the nut to the specified torque.

a - Water hose to expansion chamber

b - Nut and washer (M8)

c - Air compressor oil inlet hose

d - Oil hose to top main bearing

e - Oil hose to #5 reed block

Loading...

Loading...