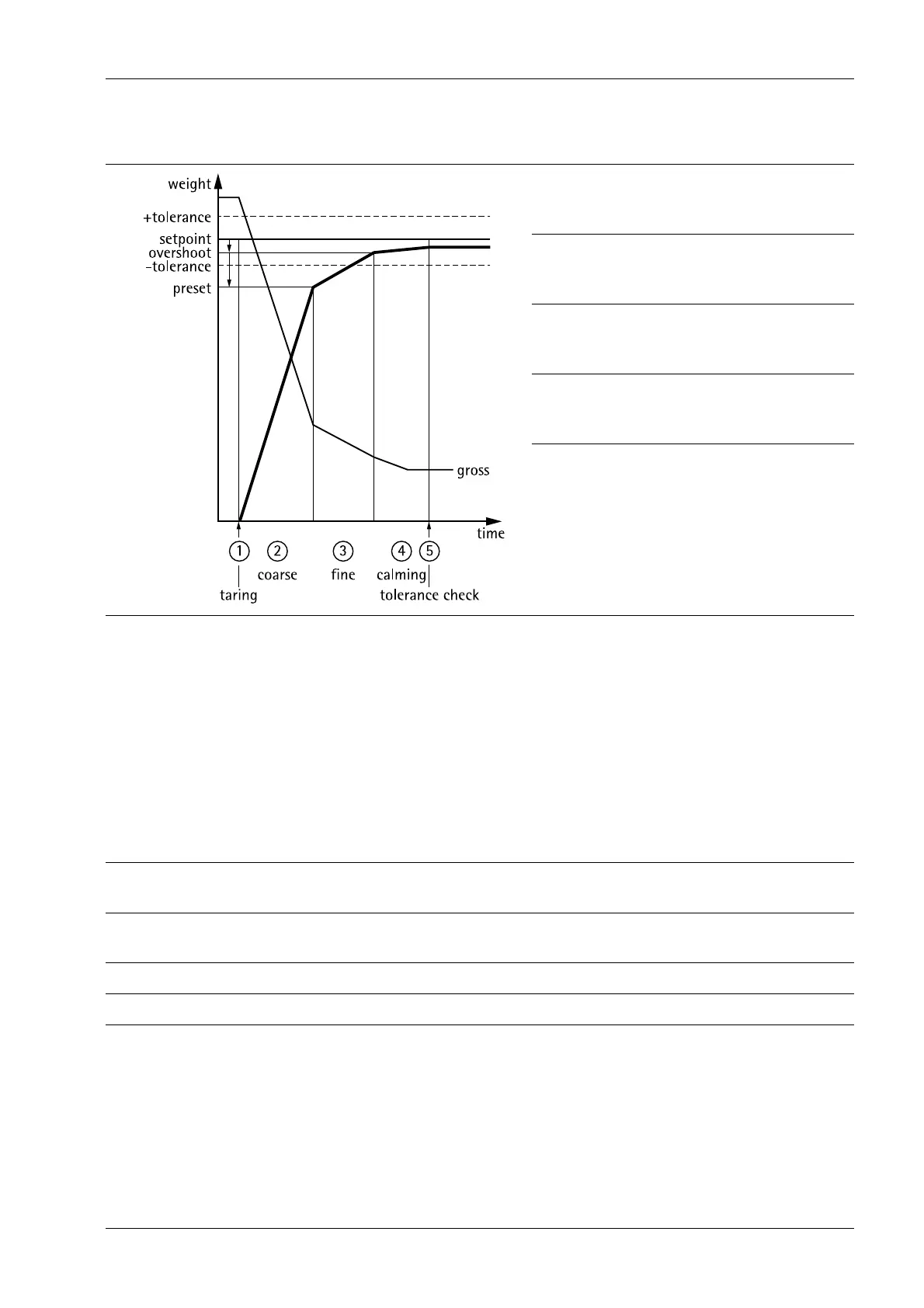

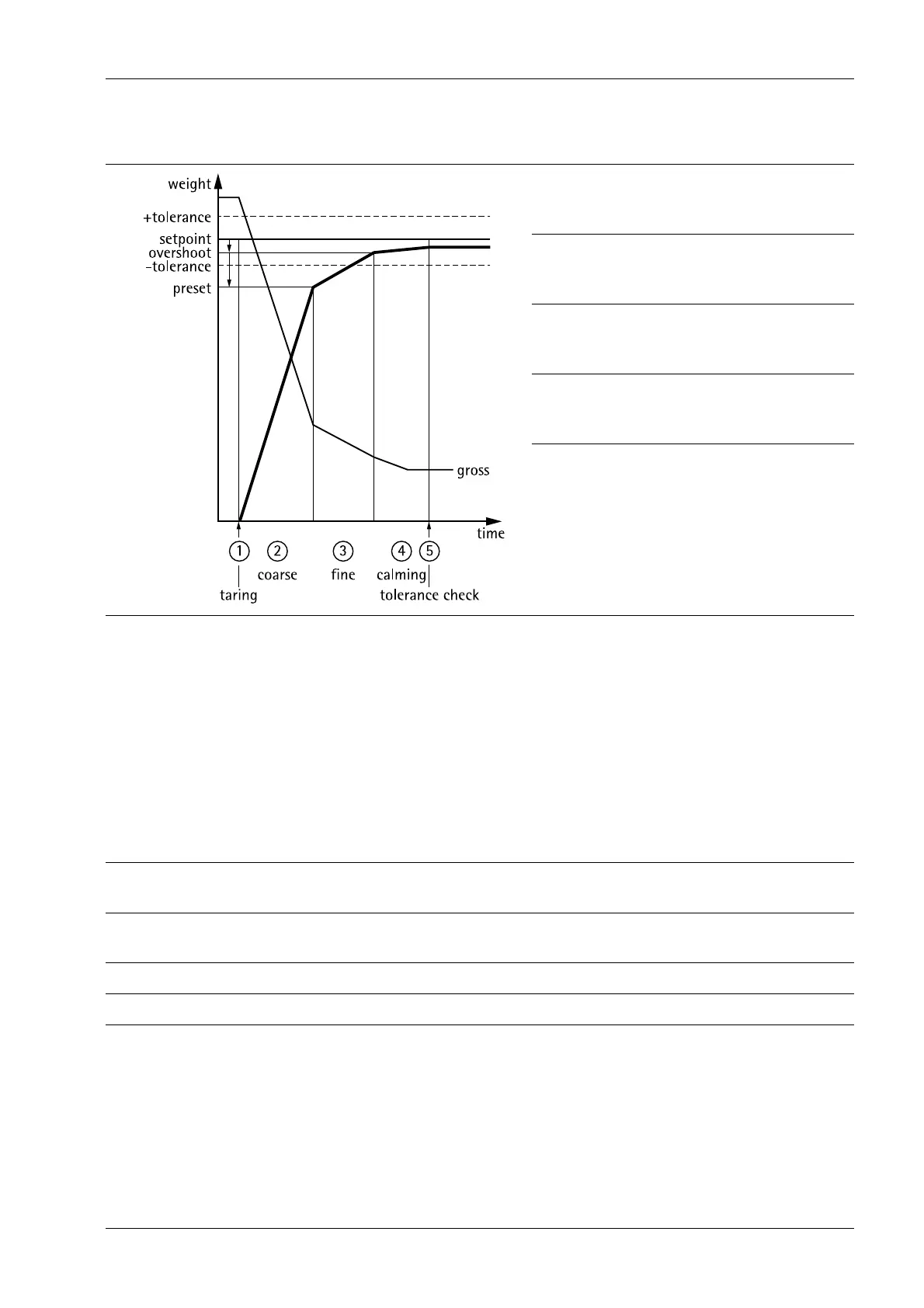

Sequence of [Net decrease] with dosing signals "coarse/ne"

①

Taring:

The current gross weight is saved as the ta-

re and the net weight starts at zero.

②

Coarse:

A coarse ow (coarse and ne) is batched

until the preset value is reached.

③

Fine:

A ne ow is batched until the switch-o

point (overshoot) is reached.

④

Calming:

Time to wait during which the overshoot is

eective and scale vibrations may settle.

⑤

Tolerance checking:

The weight is determined and checked

against the tolerance values.

8.4.1.3 Interaction mode

You can choose between the following control/operating modes of the device in

production:

- [Remote proc. control] via OPC/ModBus and/or eldbus

- [VNC] (Virtual Network Computing)

- [Front keys]

The following table shows how individual modes are locked when production starts.

Starting production

Mode Front panel VNC Remote control

OPC/ModBus

Remote control

eldbus

Digital inputs Digital out-

puts

[Remote proc.

control]

✘ ✘ ✘ ✘

[VNC]

✘ ✘

[Front keys]

✘ ✘

8.4.2 Conguring digital inputs and outputs

SPM addresses are assigned to the digital inputs and outputs under the [Conguration

digital IOs] menu item.

8 Production X3 Process Indicator PR 5410

EN-257 Minebea Intec

Loading...

Loading...