Chapter E: Basic repair procedures 2 Basic repair procedures

Technical manual Planmeca PlanMill 40 151

3. Disconnect the copper tubing line from the pump discharge 90 ell located on the top of

the pump.

This compression fitting connection is reusable without replacing the ferrule.

Loosen the connection using the two keys, using the second key to back up the

torque applied to the fitting so as to minimize or eliminate the stress imposed on the

pump housing.

4. Use clip-ring pliers to release the clip-ring and slide up the tube off the hose barb

fitting.

5. Slide the suction line tubing off the 90 degree plastic hose barb fitting until free.

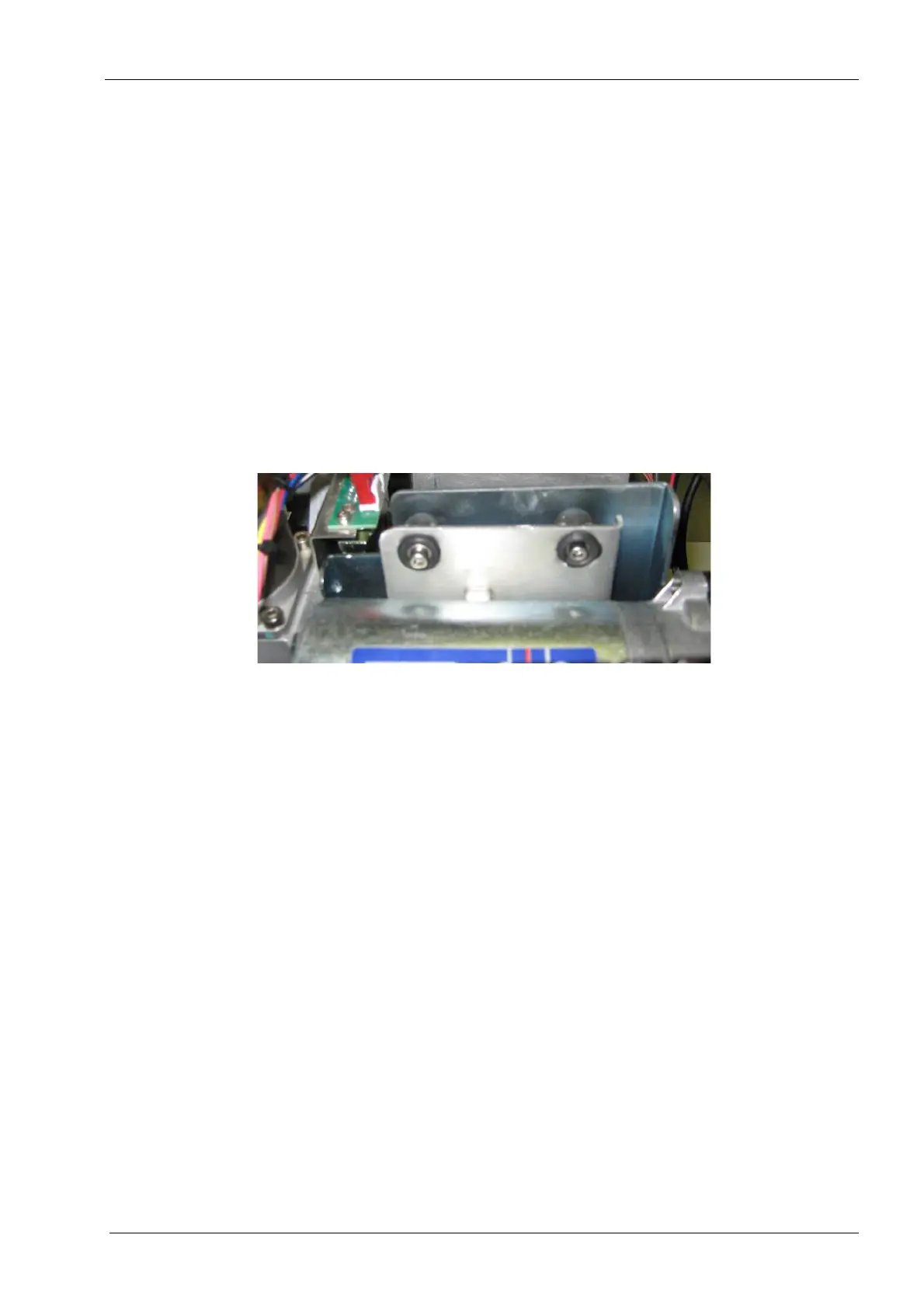

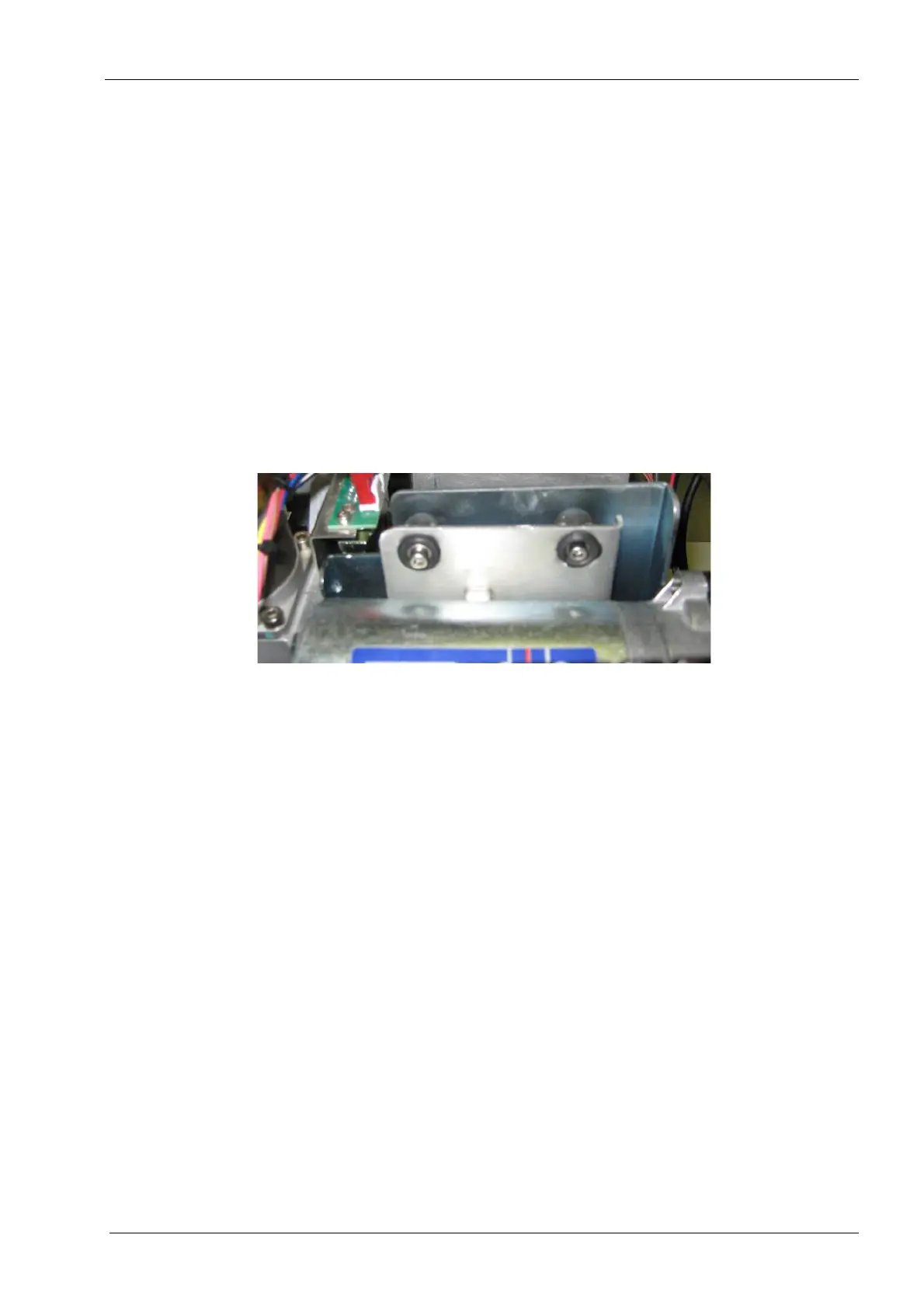

6. Locate and remove the two mounting screws and washers securing the pump to the

Pump Stand. They are located on top of the pump and can be removed using a 3 mm

Allen key.

Figure 161: Circulation pump mounting screws (viewed from back of PlanMill 40)

7. Lift the pump up and out of the machine taking care not to damage the solenoid valve

assembly behind the pump. You may find it easier to slide the pump out the right side

of the machine.

8. Note depth of engagement and orientation of fittings relative to pump, and then

remove both the suction and discharge fittings for re-use.

Install

1. Reinstall the suction and discharge fittings onto the new pump such that the depth of

thread engagement and final orientation are the same as when removed from original

pump.

No Teflon tape or paste is required when one of the two fittings is made of plastic as is the

case here.

2. Position the lower rubber mounts of the pump base into the flange pocket on the

pump stand and align the upper rubber mounts to the tapped holes on the pump

stand.

3. Insert the securing screws and washers through the upper rubber mounts and thread

into the Pump Stand.

Use blue thread locker on mounting screws.

Loading...

Loading...