Chapter E: Basic repair procedures 2 Basic repair procedures

Technical manual Planmeca PlanMill 40 173

Attempting to remove motor with coupling attached will break or damage coupling.

8. Use a 4 mm Allen key and remove (4) screws securing the servo motor to the motor

mount and carefully lift the motor up out of chassis.

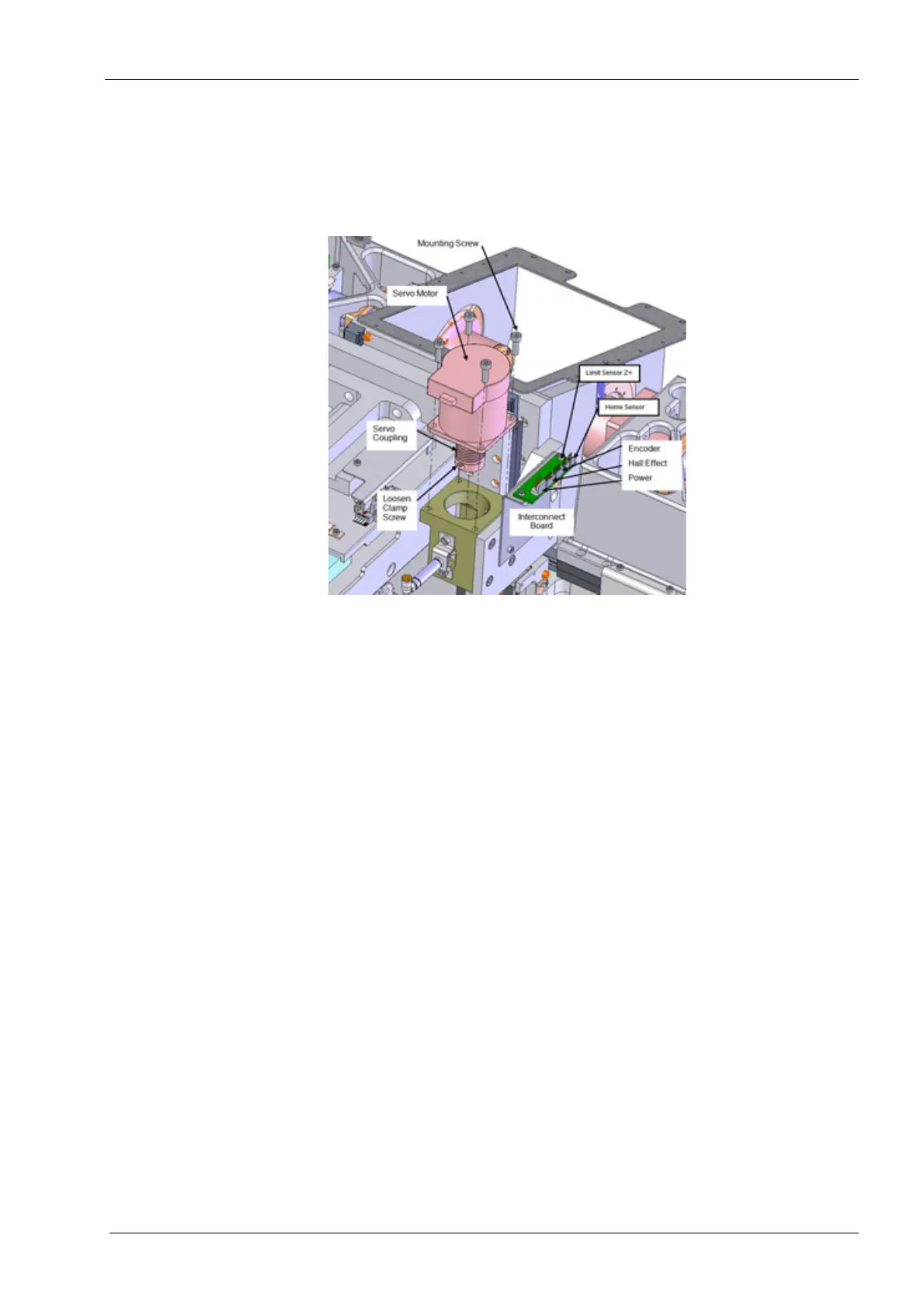

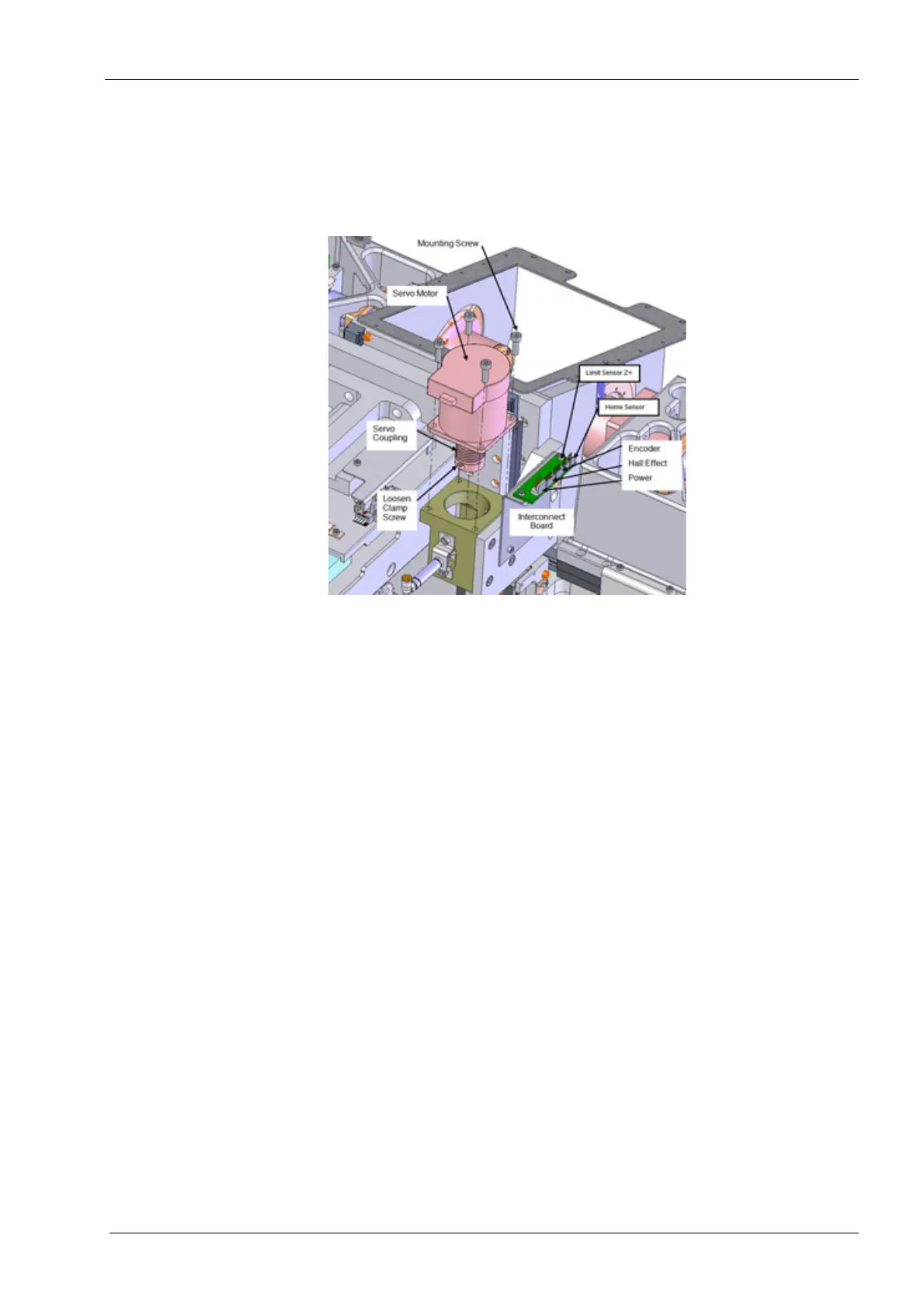

Figure 187: Removing Z-axis servo motor with coupling

Install

Installation of a new servo motor requires a careful alignment procedure, described

in the following steps. Failure to follow the alignment procedure can cause prema-

ture failure of mill components.

1. If not already installed, install the servo coupling on servo motor shaft.

The proper distance between the motor face and the servo coupling is 7 mm.

2. Torque to 2.03 nm (18 in-lbs).

Use a 7 mm Allen key as a spacer to set coupling motor shaft.

Loading...

Loading...