2 Maintenance procedures Chapter B: Preventive maintenance

36 Planmeca PlanMill 40 Technical manual

Figure 26: Spindle cap

Each spindle has a removable nozzle cap that directs 4 jets of coolant at the tip of the tool.

Due to the relatively small diameter of the nozzles periodic removal of the cap and clearing

of the nozzles may be required. The PlanMill 40 software reminds the operator to clean

the nozzle caps on a periodic basis; however the operator or technician may choose to

clean the caps at any time by following the procedure below.

The milling unit uses pneumatically operated collects to secure the various grinding tools

to the spindle. Periodic cleaning of these collets is required to maintain the optimum

performance and to ensure long life time of the collects.

The following procedure is identical for both left and right spindle.

During this procedure expect air to be expelled or purged through the spindle shaft. This is

normal. The purging air helps to expel coolant and loose debris from the spindle shaft and

prevent contamination of the spindle bearings.

Tools required

• Planmeca PlanMill 40 user maintenance kit

•Dental mirror

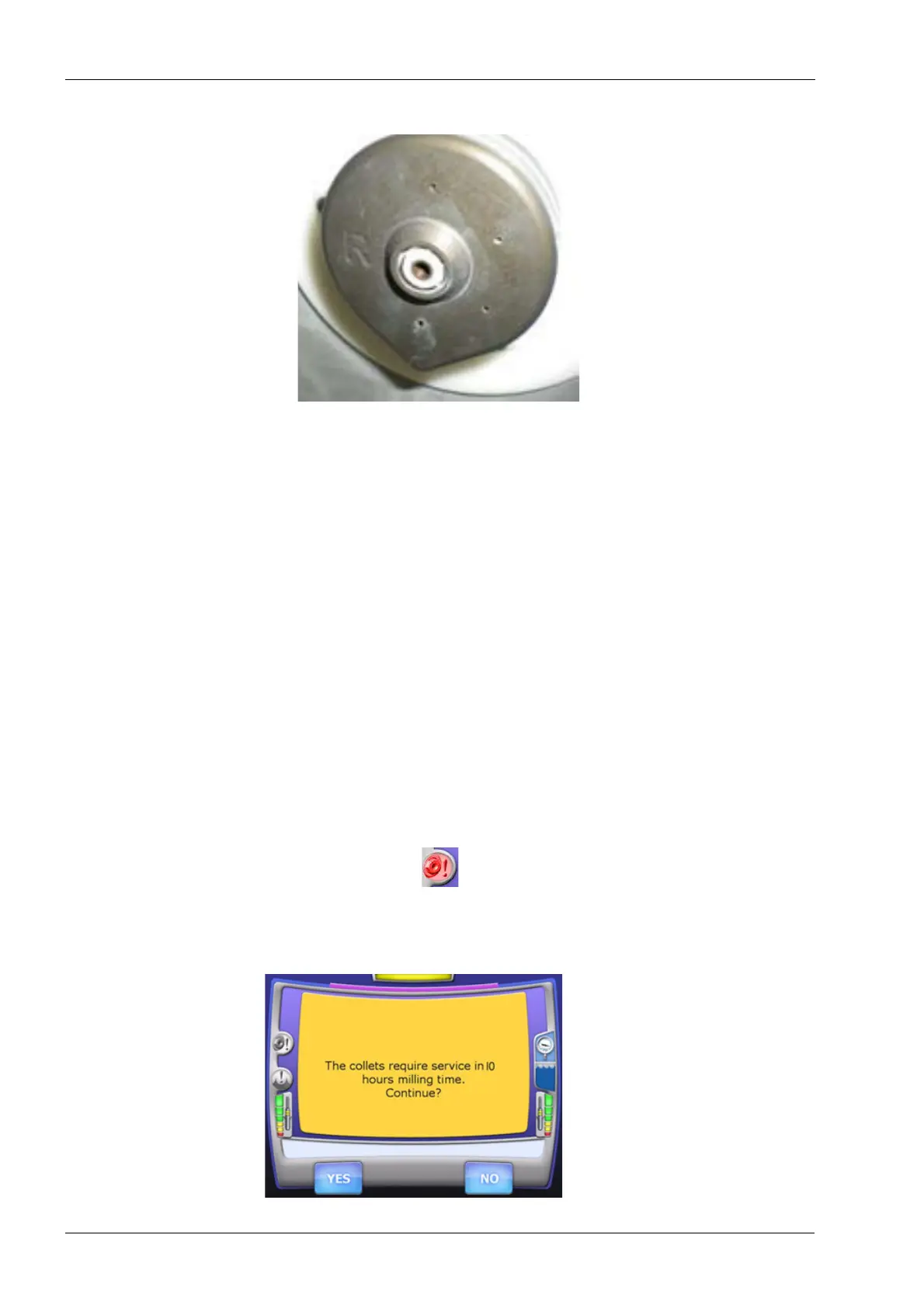

1. Touch and hold the Collet Cleaning icon.

A message appears and shows the number of hours remaining before a scheduled

cleaning is needed.

Figure 27: Collet cleaning message

Loading...

Loading...