2 Maintenance procedures Chapter B: Preventive maintenance

38 Planmeca PlanMill 40 Technical manual

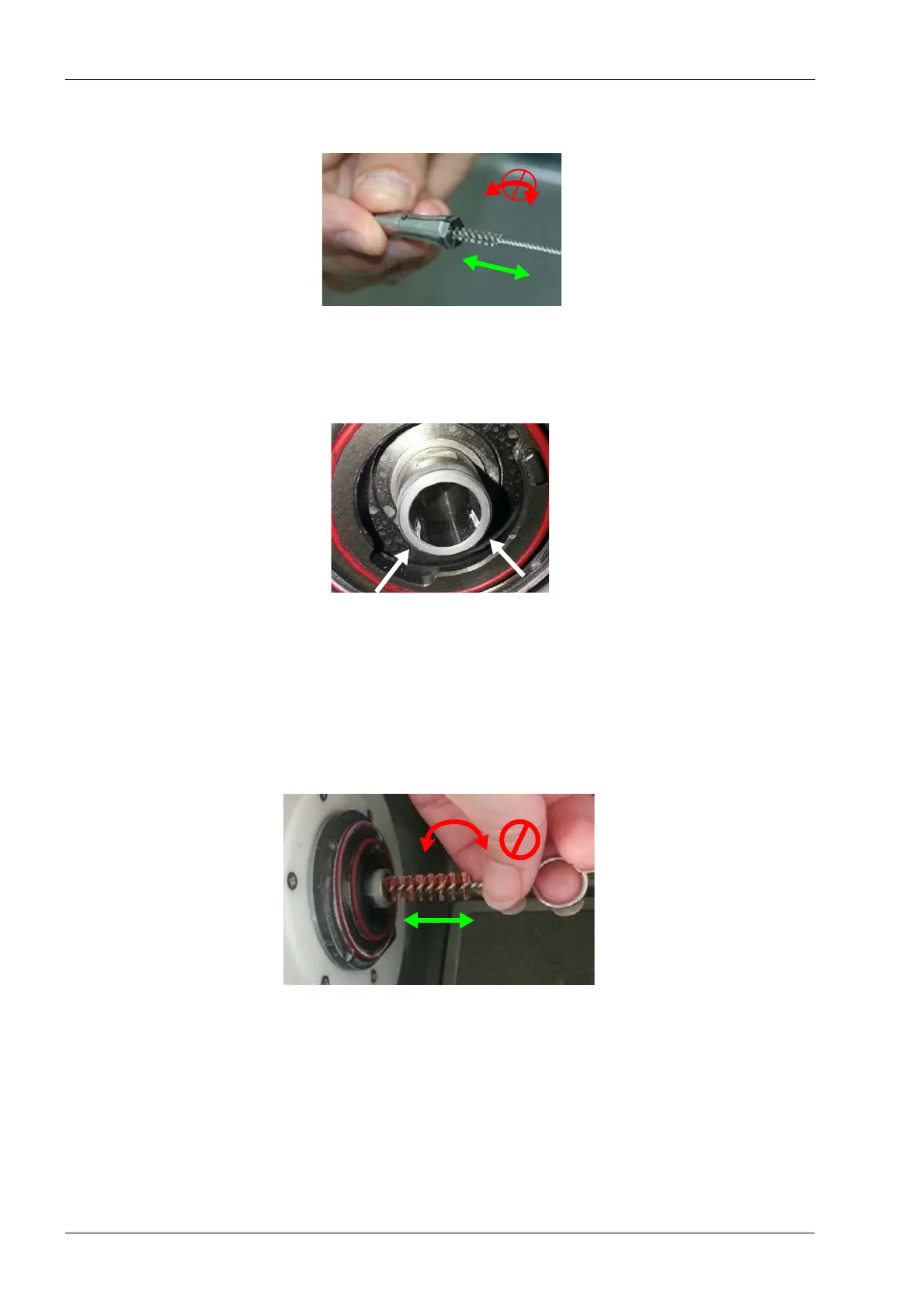

5. Rinse the collet and use the small silver wire brush to clean the inside, running it

through a couple of times.

6. Clean also the outside of the collet. Any debris on the collet will cause the tool to not

seat properly.

7. In the spindle (collet shaft), you are likely to see 3 lines of debris that need to be

cleaned. These are from the slits in the collet. If they are not cleaned, the collet will not

seat properly and will lead to “walking tools”.

The lines are not necessarily going to be positioned as seen in the example above.

There will be three equidistant lines. The top one cannot be seen from the angle

shown.

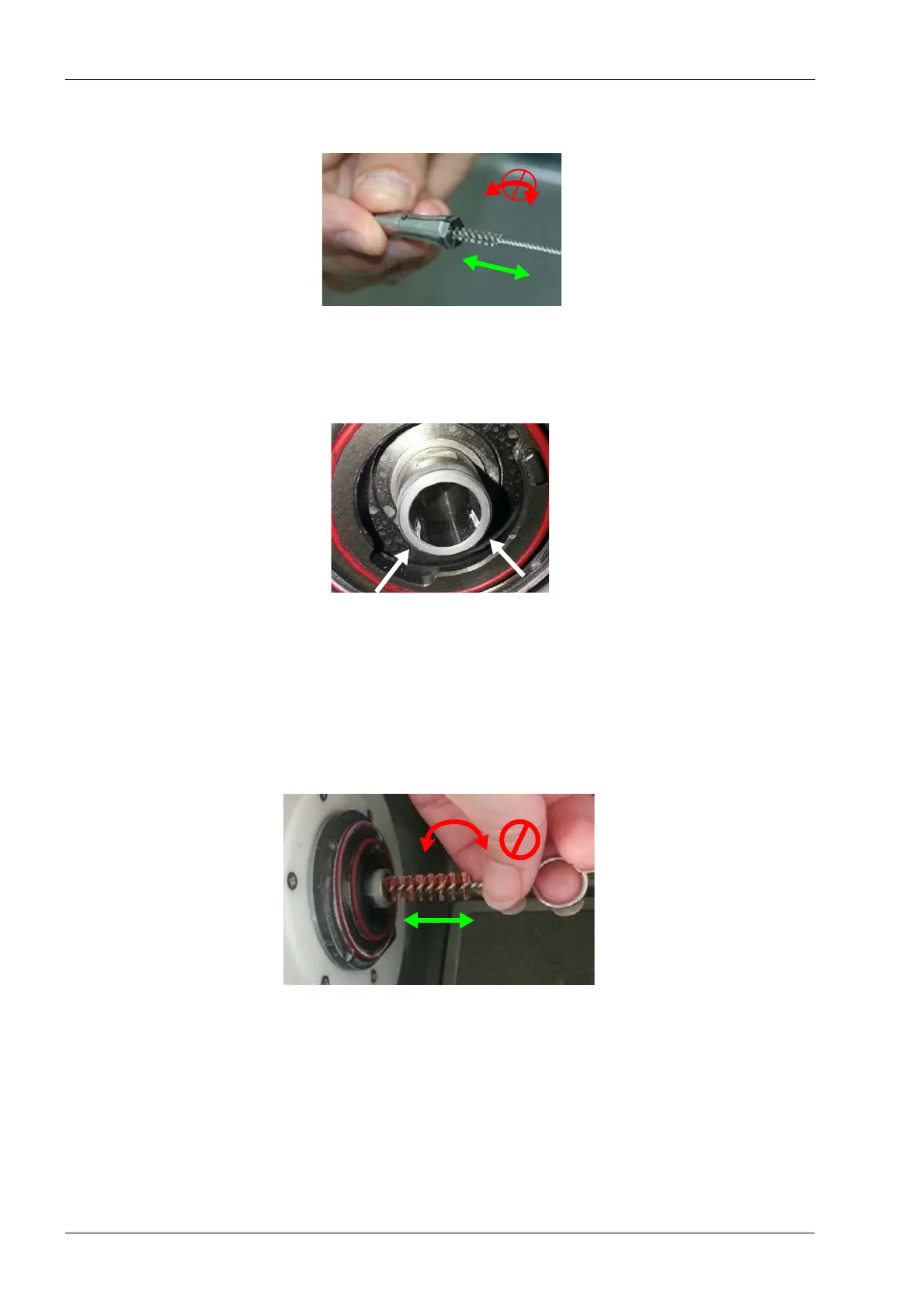

8. Use the larger bronze wire brush in the collet shaft.

The air must be blowing during this step.

Be sure to use straight in and out -motion. Do NOT use circular motion.

9. Use a dental mirror to inspect the spindle or rotate the spindle using the wrench to

ensure all the debris has been removed.

10. Use a DRY paper towel to wipe the inside of the collet shaft.

To keep your milling unit running smoothly it is very important to clean the collets and

spindles. Dirt will cause the tools to “walk” (not be seated properly) and can cause

broken tools.

Loading...

Loading...