2 Troubleshooting Chapter D: Troubleshooting

88 Planmeca PlanMill 40 Technical manual

Checking home and limit sensor status

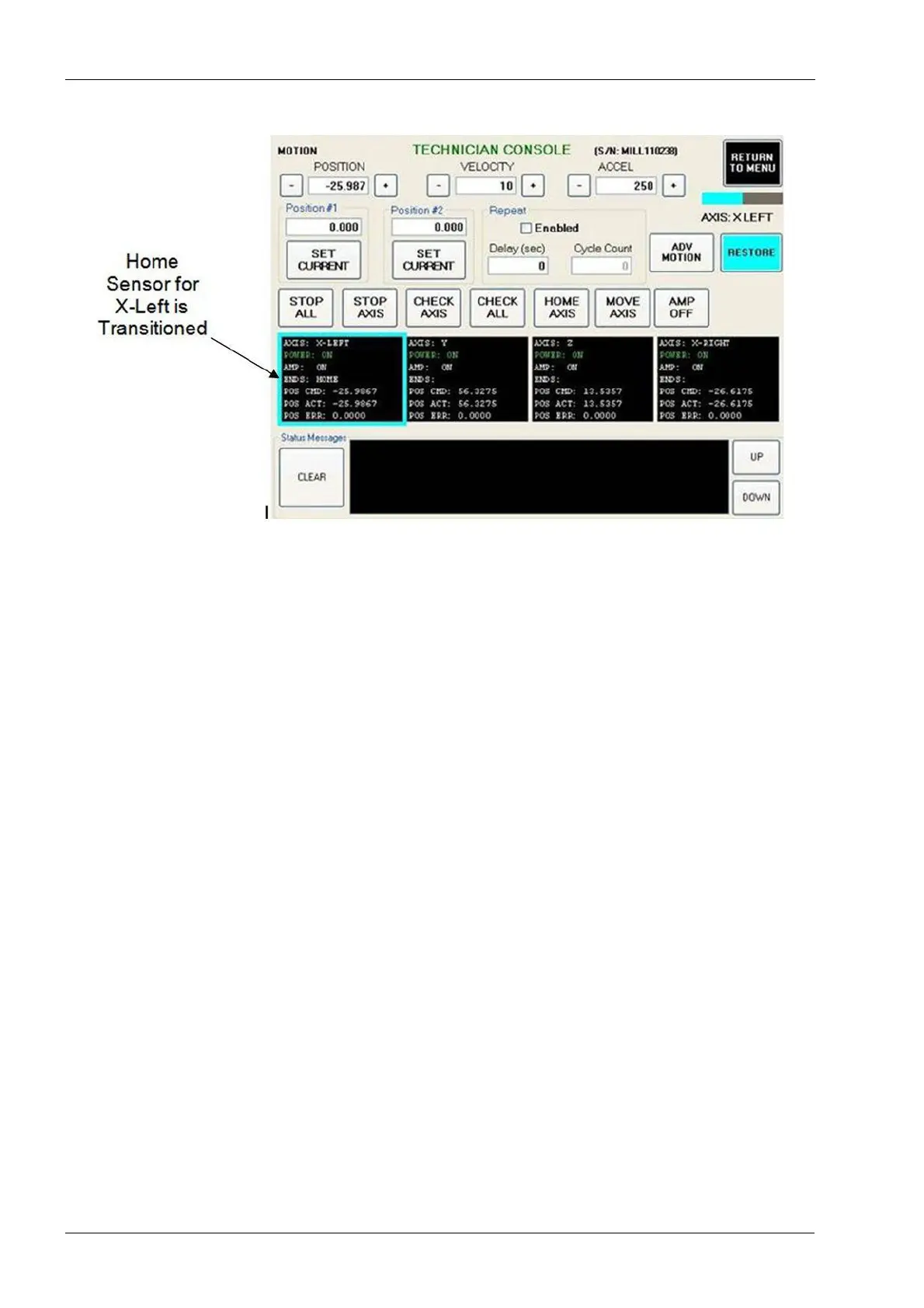

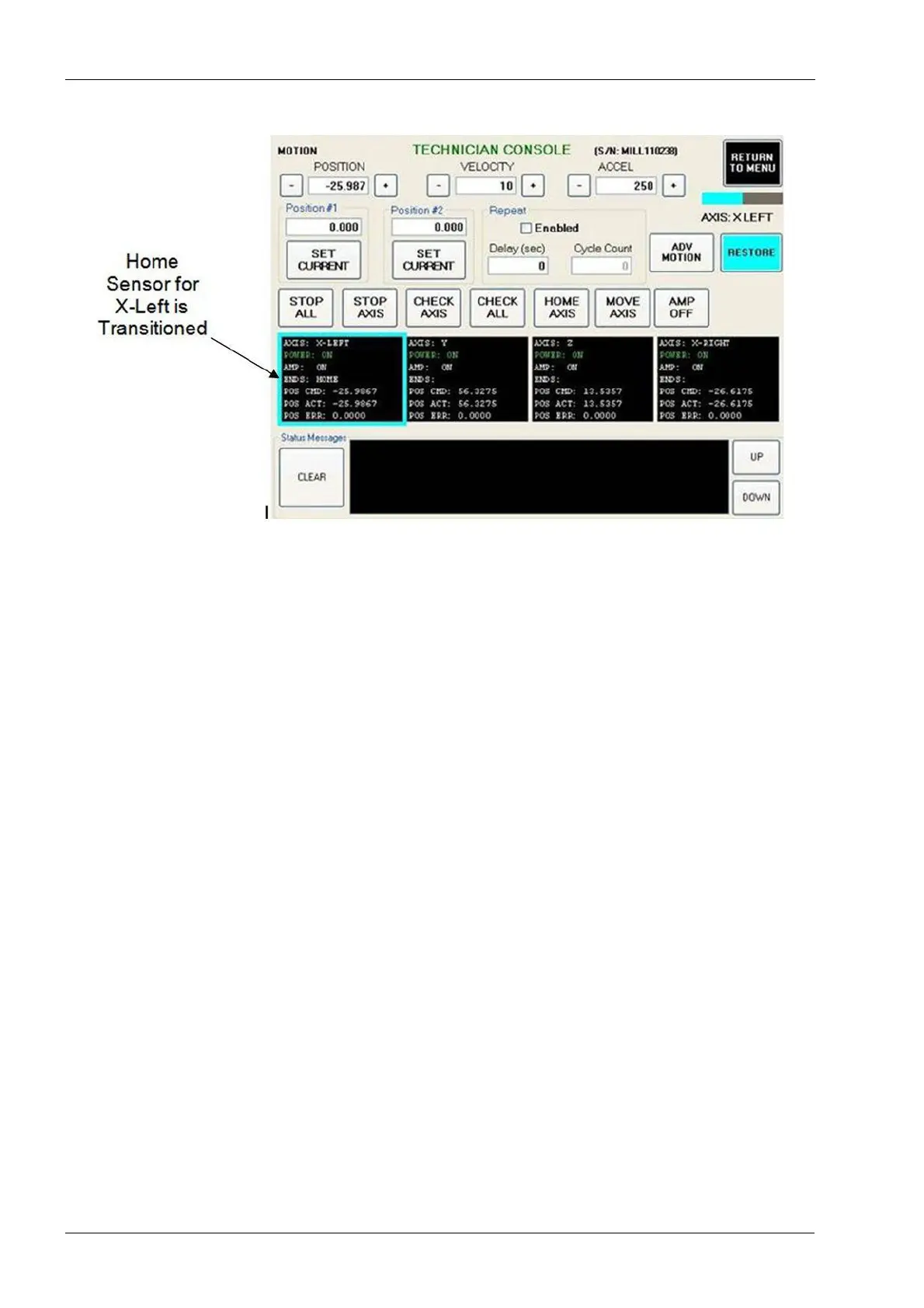

14. Check home and limit sensor response for each axis.

• Use a business card or similar object to transition each home and limit sensor for

each axis. The word “Home” or the word “LIMIT” depending on which sensor is

being checked should appear in the space next to “ENDS:” in the Axis for the

sensor being checked.

The response in the GUI may take a second or two to appear.

• If you find a Home sensor not transitioning in the GUI, then the sensor and/or its

cable may be defective. A home sensor must be functioning properly for the

motion system to initialize. Replacing the sensor and its cable together is

recommended to minimize the customer's down time.

Replacing a Home sensor requires full calibration of the mill.

• If you find an end-limit sensor not transitioning in the GUI, then the sensor and/or

its cable may be defective. An end-limit sensor isn't required for the motion

system to initialize. However, if it is stuck in the "Closed" state the initialization will

fail. A temporary solution would be to unplug the end-limit sensor and leave it

unplugged if the replacement sensor and/or its cable are not immediately

available.

15. With the lid open, check each axis manually for smooth movement throughout the full

stroke (home to end-limit and then back to home).

• If an axis is found that can’t be physically moved from home to end-limit and then

back to home, then check for obstructions that may prevent the movement (i.e.

Cables, loose hardware, damaged sliding wall, pre-Rev E hinge plate assembly

in the lid adapter assembly, etc.).

Loading...

Loading...