INTRODUCTION

A00A3UA

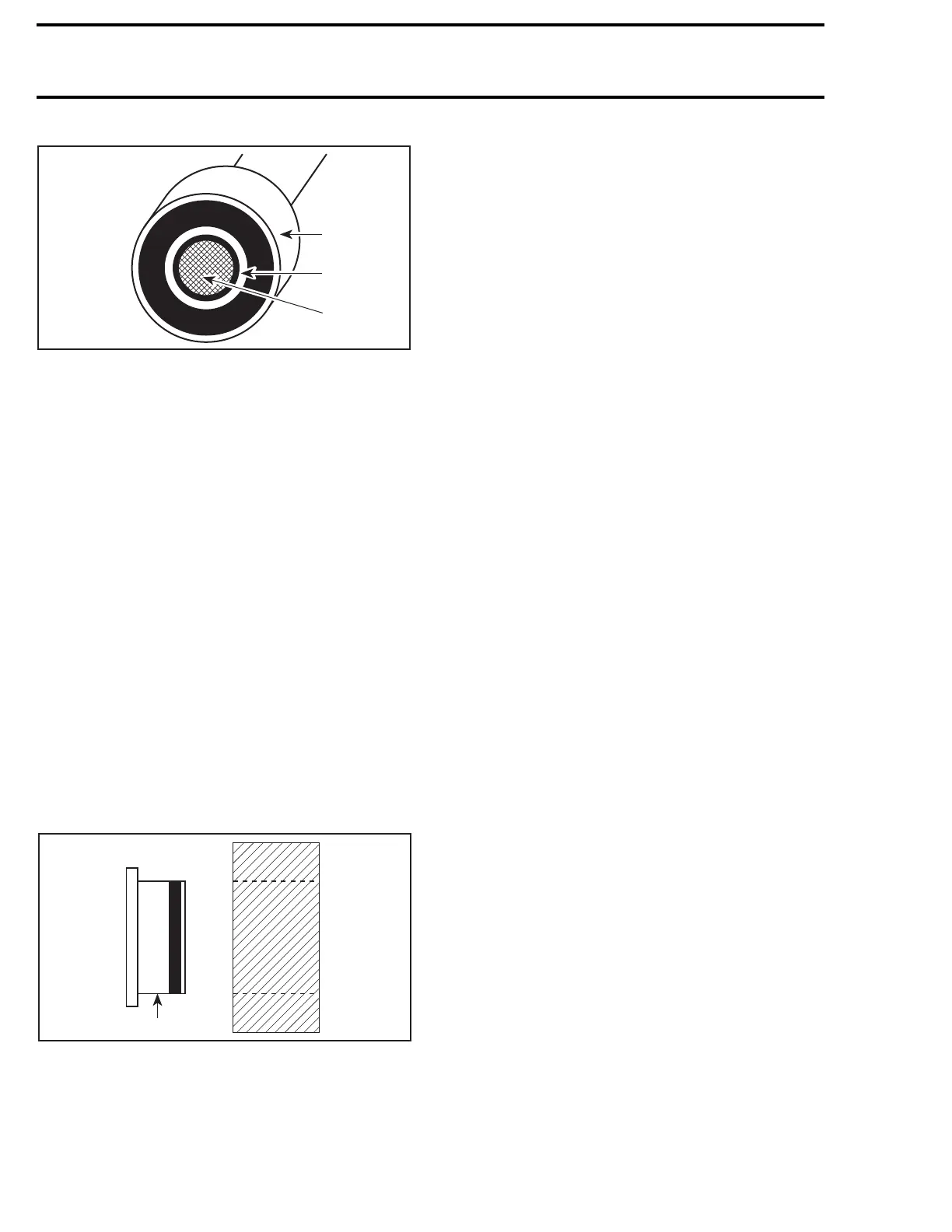

1

2

3

1. Bearing

2. Proper strength Loctite

3. Shaft

1. Clean shaft external contact s urface.

2. Clean internal contact surface of part to be in-

stalled on shaft.

3. Apply a strip of proper s trength Loctite on cir-

cumference of shaft contact surface at inser-

tion or engagement point.

NOTE: Retaining compound is always forced out

when applied on shaft.

4. DO NOT use antiseize Loctite or any similar

product.

5. No curing period is required.

Mounting in Tandem

1. Apply retaining compound on internal contact

surface (bore) of parts to be installed.

2. Continue parts assembly as per previous illus-

tration.

Threadlocker Application for Case-In

Components (Metallic Gaskets)

A00A3VA

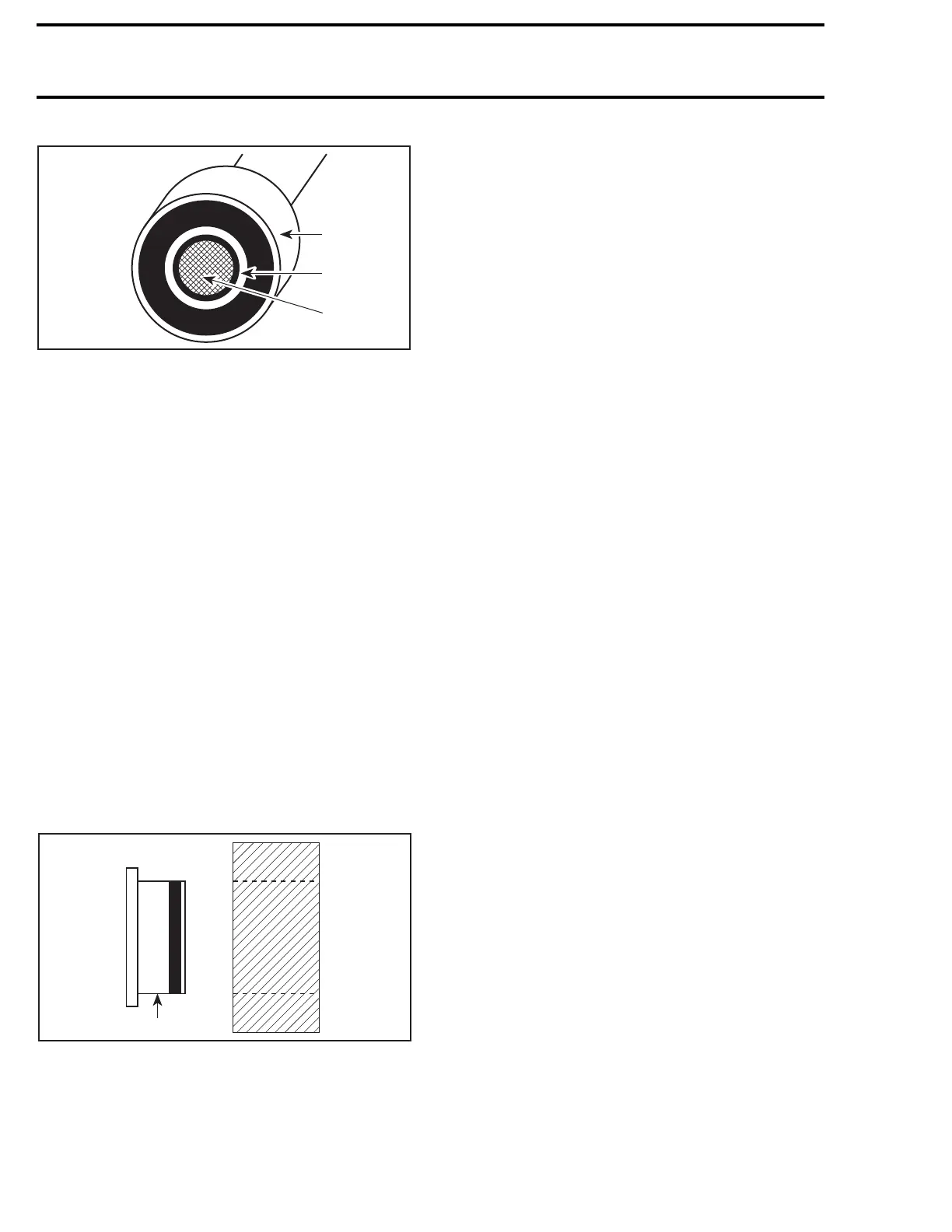

1

1. Proper strength Loctite

1. Clean inner housing diameter and outer gasket

diameter.

2. Spray housing and gasket with

LOCTITE 7649

(PRIMER)

.

3. Apply a strip of proper strength Loctite on lead-

ing edge of outer metallic gasket diameter.

NOTE: Any Loctite product can be used here. A

low strength liquid is recommended as normal

strength and gap are required.

4. Install according to standard procedure.

5. Wipe off excess product.

6. Allow 30 minutes for product to cure.

NOTE: Normally used on worn-out housings to

prevent leaking or sliding.

It is generally not necessary to remove gasket

compound applied on outer gasket diameter.

XVIII 219100963-002

Loading...

Loading...