INTRODUCTION

NOTE: If it is difficult to readjust, heat screw with

a soldering iron (232°C (450°F)).

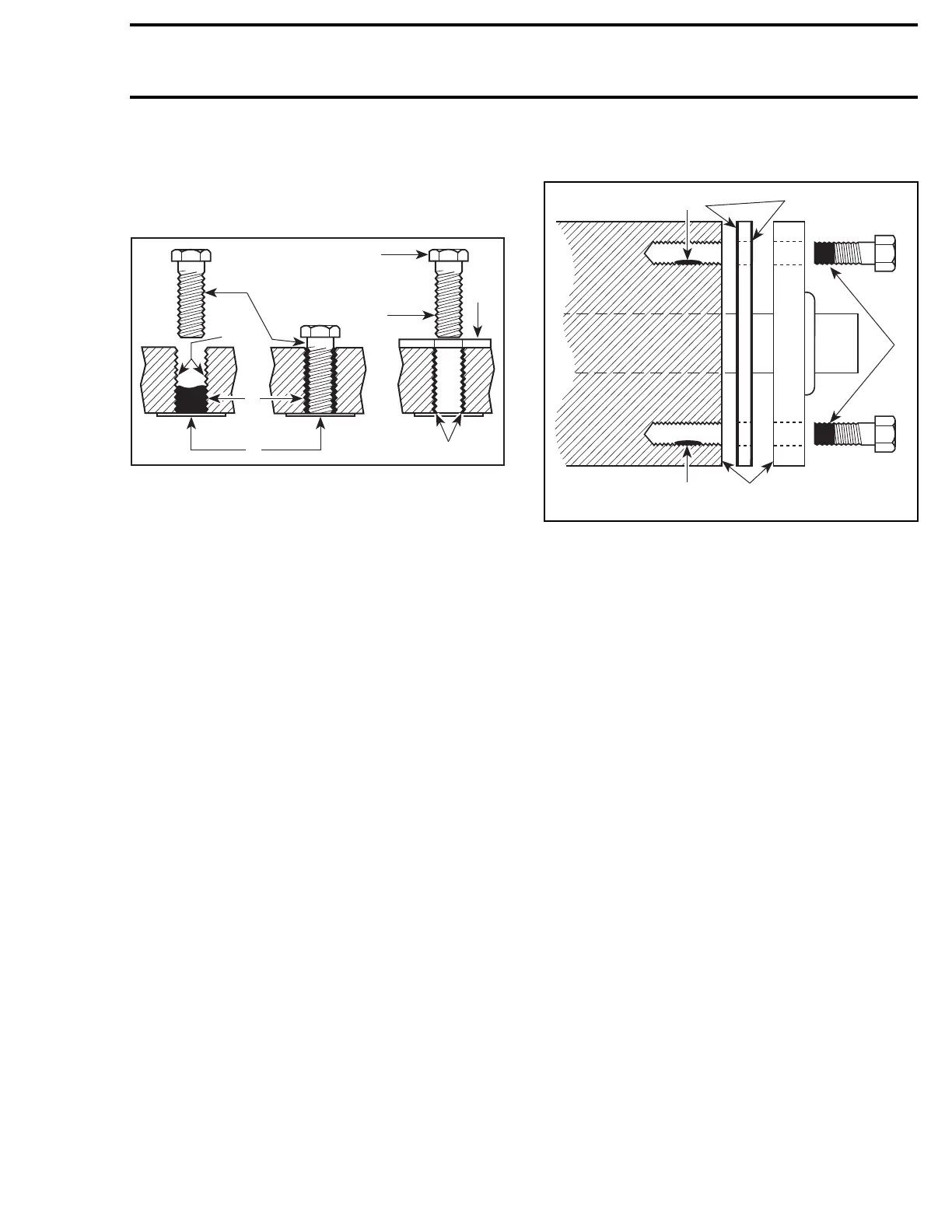

Application for Stripped Thread Repair

A00A3QA

5

8

6

7

1

2

3

4

1. Release agent

2. Stripped t

hreads

3. Form-A-Thread

4. Tapes

5. Cleaned b

olt

6. Plate

7. New thread s

8. Threadlo

cker

Standard Thread Repair

Follow in

structions on Loctite FORM-A-THREAD

81668 pac

kage.

If a plate is used to align bolt:

1. Apply release agent on mating surfaces.

2. Put waxe

d paper or similar film on the surfaces.

3. Twist bolt when inserting it to improve thread

conformation.

NOTE: NOT intended for engine stud repairs.

Repair o

f Small Holes/Fine Threads

Option 1: Enlarge damaged hole, then follow

STANDARD THREAD REPAIR

procedure.

Option 2: Apply FORM-A-THREAD on the screw

and insert i n damaged hole.

Permane

nt Stud Installation (Light Duty)

1. Use a stud of the desired thread length.

2. DO NOT a pply release agent on stud.

3. Follow

Standard Thread Repair procedure.

4. Allow 30 minutes for Loctite FORM-A-THREAD

to cure.

5. Complete part assembly.

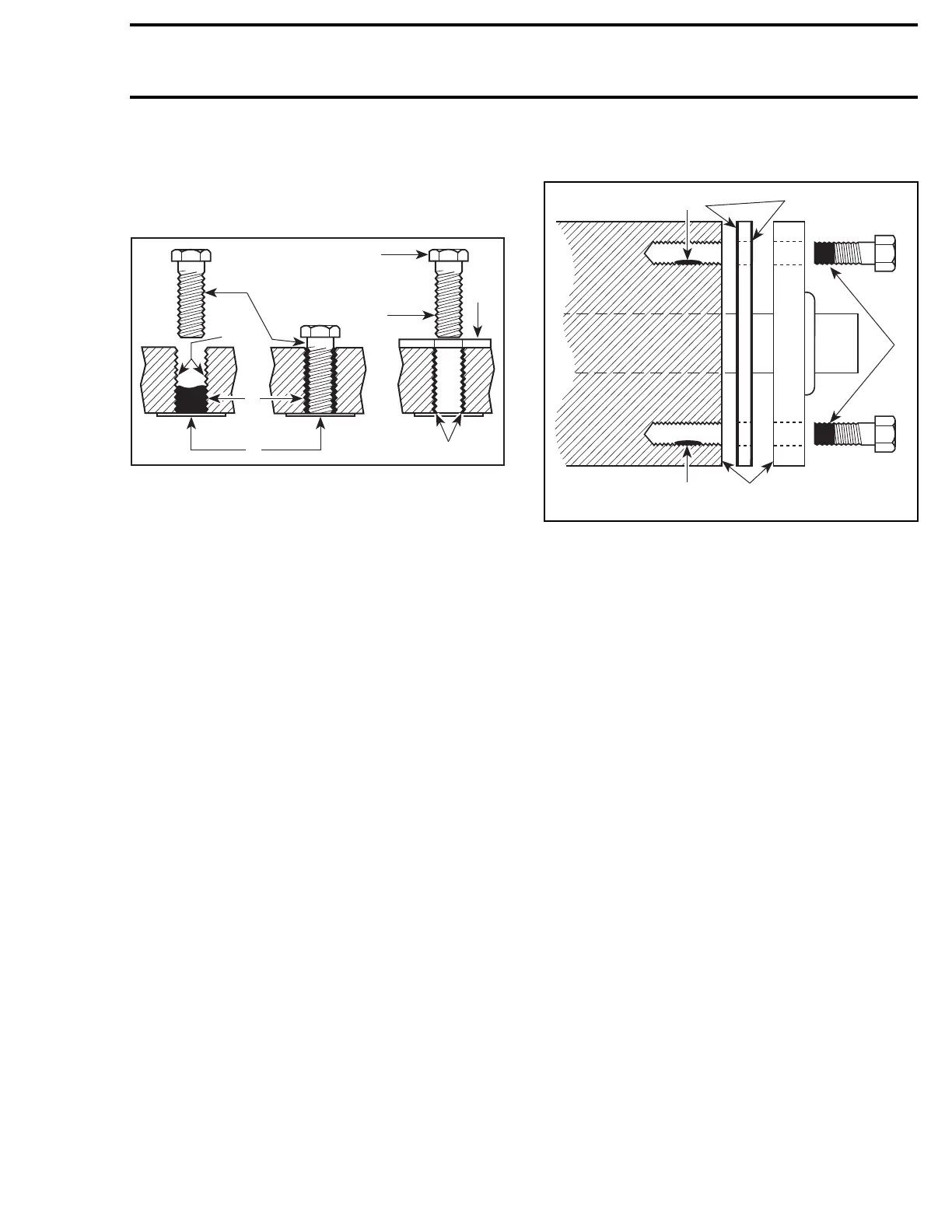

Gasket Compound Application

21

1

3

1

lmr2007-040-006_a

1. Proper st

rength Loctite

2. Loctite Primer N and Gasket Eliminator 518

on both sides of gasket

3. Loctite P

rimer N only

1. Remove old gasket and other contaminants

using

LOCTITE CHISEL (GASKET REMOVER)

.

Use a mechanical means only if necessary.

NOTE: Av

oid grinding.

2. Clean both mating surfaces w ith solvent.

3. Spray Loctite Primer N on both mating s urfaces

and on both sides of gasket and allow to dry 1

or 2 minutes.

4. Apply

L

OCTITE 518

on both sides of gasket, us-

ing a cl

ean applicator.

5. Place gasket on mating surfaces and assemble

parts immediately.

NOTE: If the cover is bolted to blind holes, apply

proper s trength Loctite in the hole and on threads.

Tighten fastener.

If hol

es are sunken, apply proper strength Loctite

on bol

t threads.

6. Tighten as usual.

Thre

adlocker Application for Mounting

on a Shaft

Mounting with a Press

219100963-002 XVII

Loading...

Loading...