Section04ENGINE

Subsection 01 (593, 593 HO, 593 HO SDI AND 793 HO ENGINE TYPES)

Follow the same procedure for the inner bearing

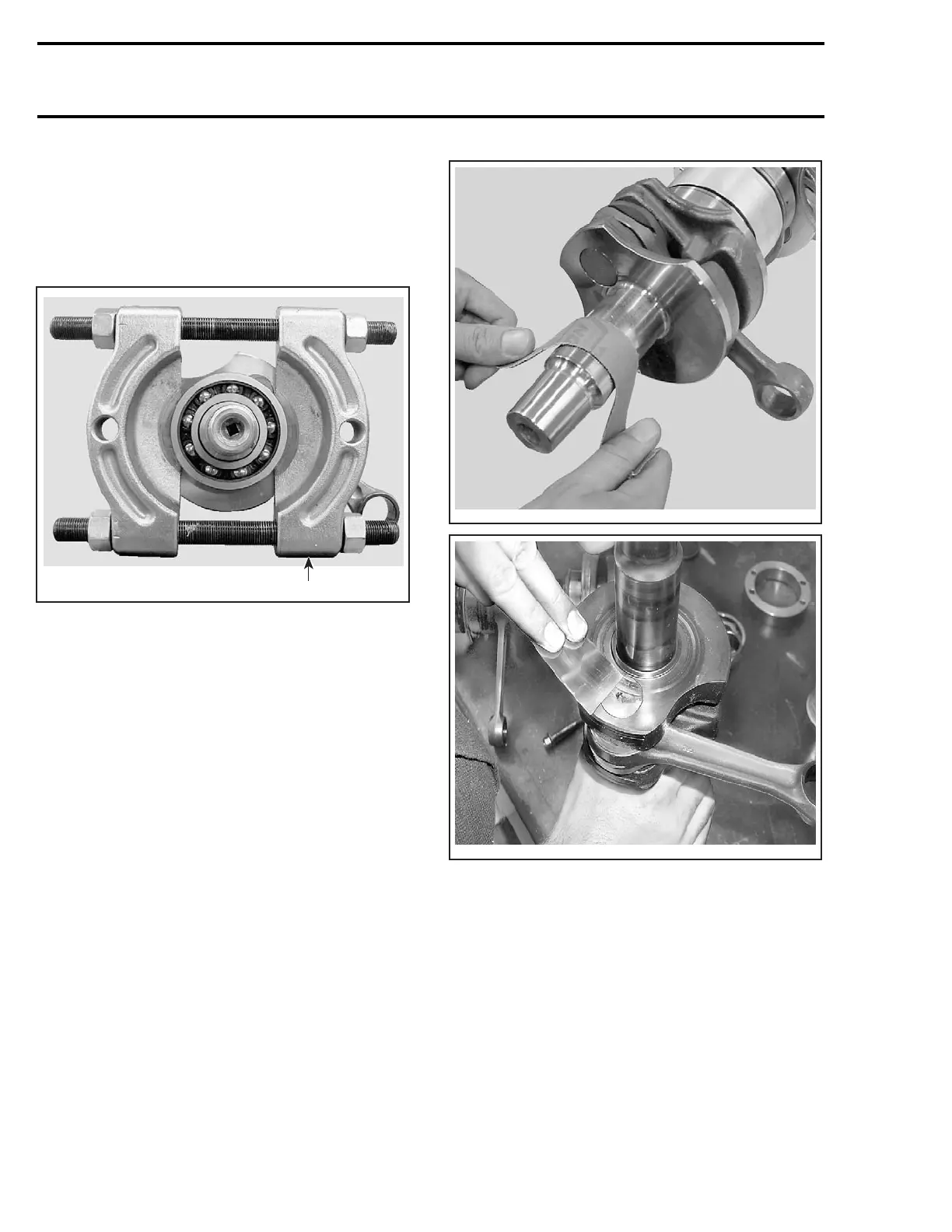

NOTE: In the case of damaged bearing or less

clearance between crankshaft counterbalance and

the bearing or on the MAG side bearing, use a

bearing separator such as Snap-On tool CJ 951 or

SPX/OTC tool 1124 to facilitate the removal.

1

A32CB4A

1. Bearing separator

INSPECTION

Refer to LEAK TEST AND ENGINE DIMENSIONS

MEASUREMENT.

ASSEMBLY

Coat lip of all seals with Petamo grease (P/N 420

899 271).

Crankshaft Bearing

CAUTION: Never reinstall a bearing that has

been removed.

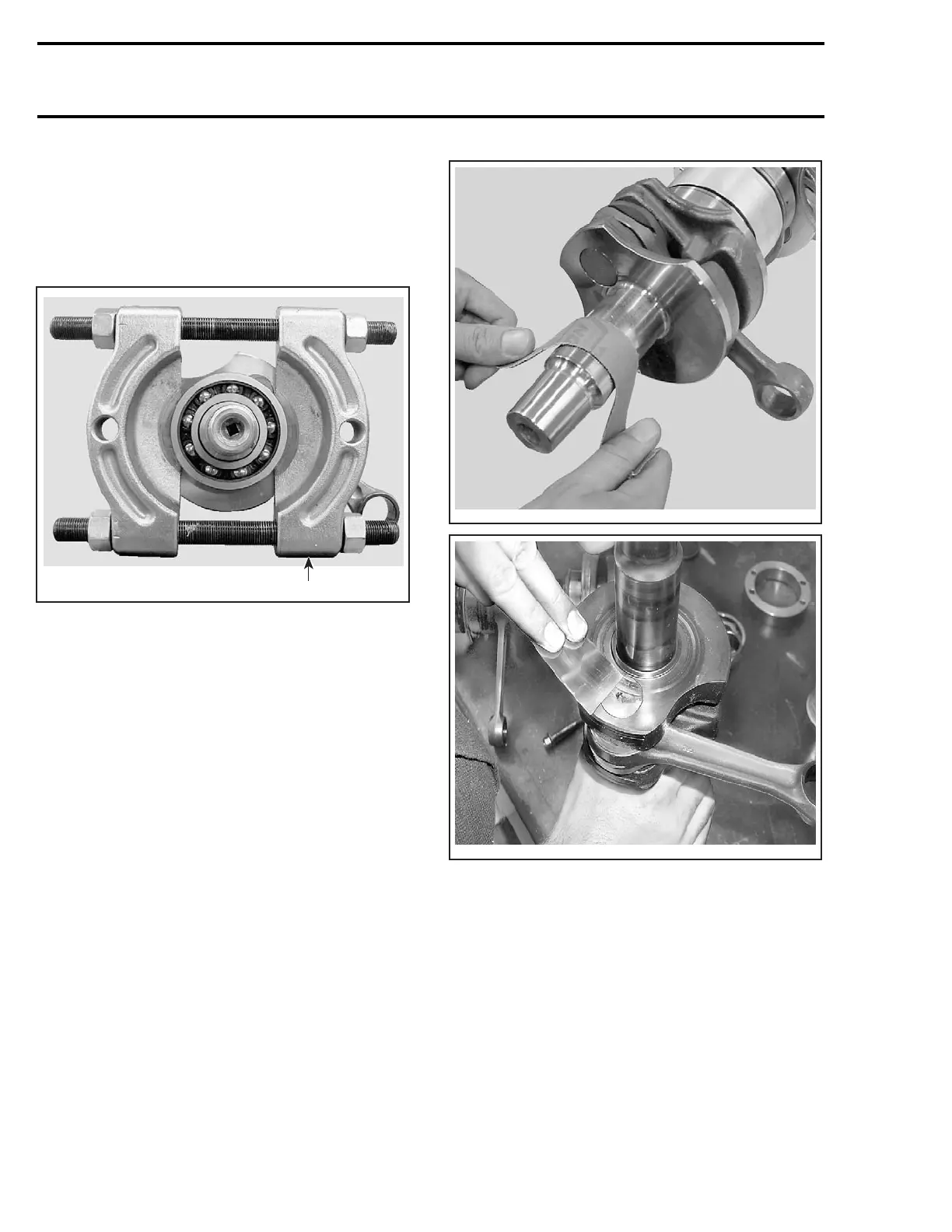

Inspect crankshaft ends for damage.

Clean crankshaft ends with sand paper no. 180 to

remove possible seal marks and debris.

A32CB5A

A32CBWB

Remove all residue using pulley flange cleaner

(P/N 413 711 809.)

Smear anti-seize lubricant (P/N 413 701 000) on

part of crankshaft where bearing fits.

104 mmr2004-Rev

Loading...

Loading...