Section04ENGINE

Subsection 08 (FUEL TANK AND FUEL PUMP)

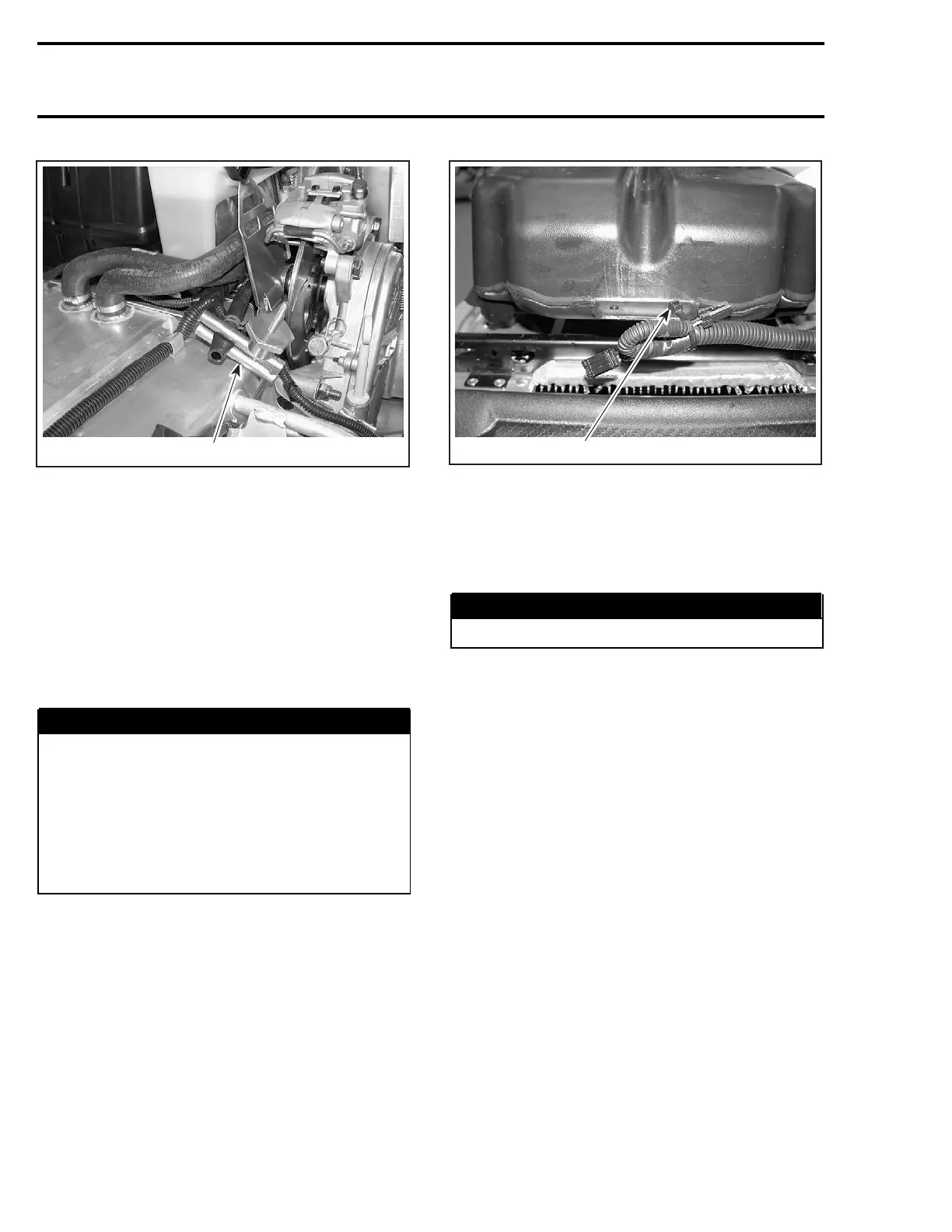

1

A33F10A

FUEL TANK REMOVED

1. Hose pincher installed on fuel line

SDI Models

Release fuel pressure of the system. Refer to

COMPONENT INSPECTION AND ADJUSTMENT.

Empty fuel tank no. 3.

Install a hose pincher on fuel pump hose no. 5

then disconnect it from fuel line no. 1.

Unplug fuel pump connector.

All Models

WARNING

Whenever a fuel line is disconnected, ob-

struct line with a hose pincher (P/N 295 000

076) or (P/N 529 032 500). Fuel is flammable

and explosive under certain conditions. Al-

ways wipe off any fuel or oil spillage from the

vehicle. Ensure work area is well ventilated.

Do not smoke or allow open flames or sparks

in the vicinity.

Unplug vent tube no. 2 from tank.

Some Models

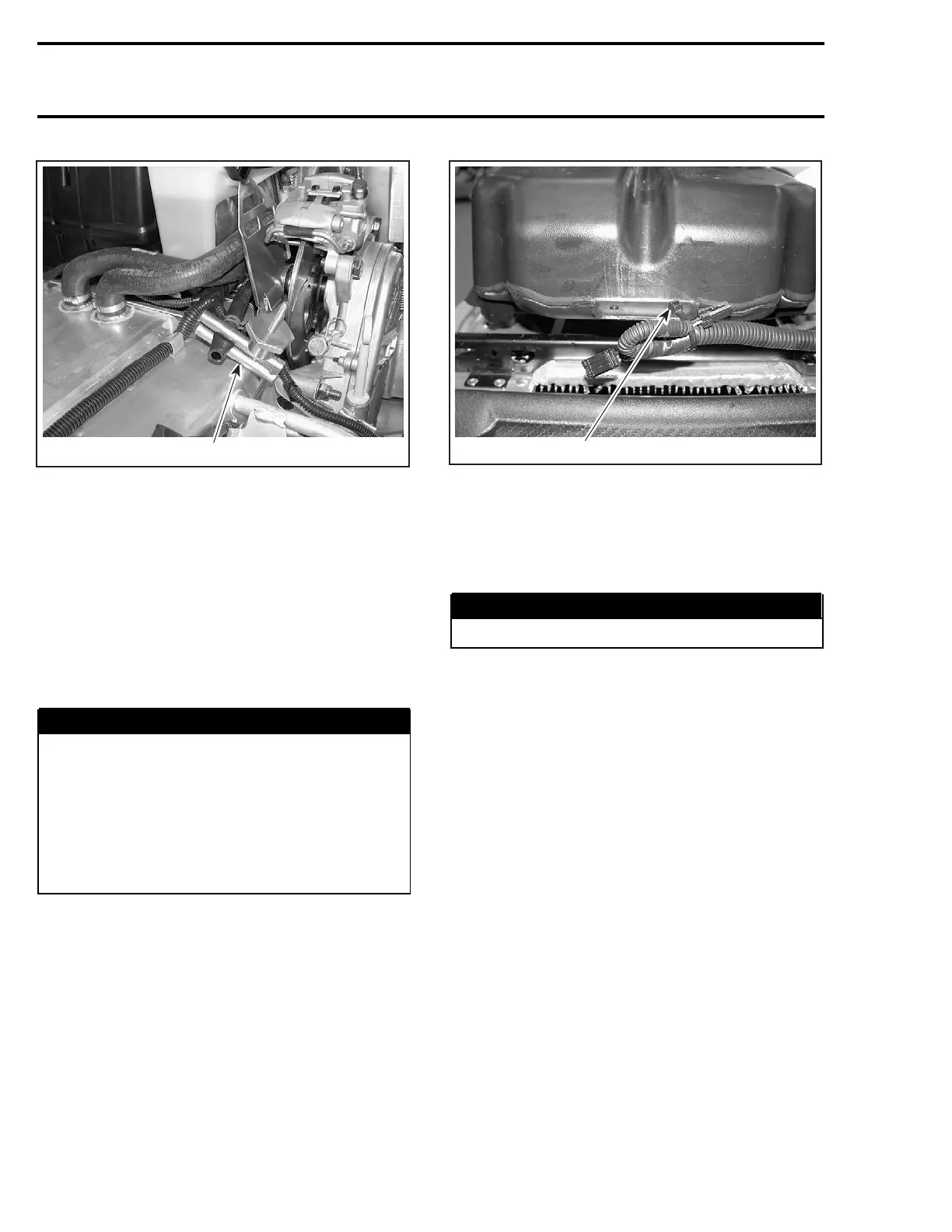

Cut locking tie holding wiring harness to fuel tank

at rear.

1

A33F11A

1. Cut this locking tie

Remove fuel tank no. 3 and set it aside.

Installation

Reinstall fuel tank and plug-in vent tube.

WARNING

Make sure vent tube is not kinked.

Connect fuel line and remove hose pincher.

Reinstall right and left fuel tank aluminum braces

using new lower Torx screws (with Scotch Grip)

and previously removed upper flanged hexagonal

bolts with new M8 flanged elastic stop nuts.

Reinstall filler neck nut using special tool (P/N 529

035 891).

Reinstall fuel cap.

Reinstall center console.

Reinstall console center trim cap.

Reinstall seat.

SDI Models

Perform a fuel pressure test and a fuel bleeding

procedure. Refer to COMPONENT INSPECTION

AND ADJUSTMENT.

IMPULSE/FUEL LINES SPRING

CLIPS (ALL MODELS)

Always reposition spring clips after any repair to

prevent possible leaks. If a spring clip seems

loose, replace it with a new one.

160 mmr2004-Rev

Loading...

Loading...