Section052–TEC ENGINE MANAGEMENT

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

Unscrew all retaining screws and remove the en-

gine ECM from its support.

Install the new ECM to the support.

Reconnect ECM connectors to ECM, and then bat-

tery cables.

Transfer the data from the previous ECM to the

new one using B.U.D.S. then proceed with the

required resets and reprogram tether cord cap(s),

ifyouwereunabletotransferthedata.

NOTE: If data cannot be transferred, manually en-

ter information in Vehicle tab.

After performing the required resets, ensure to

clear all faults from the newly replaced ECM.

Start the engine and increase engine speed above

5000RPMtobesurenofaultappears.

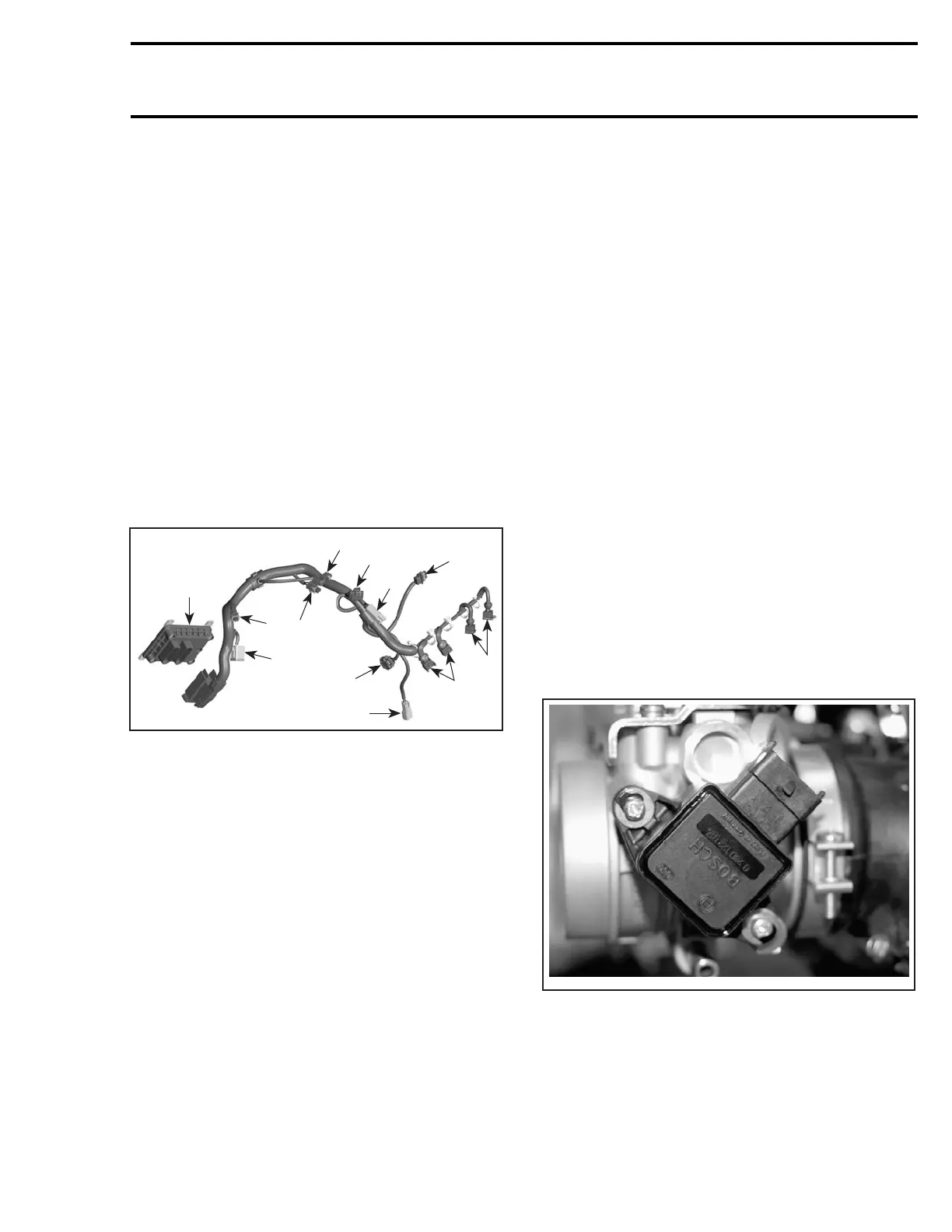

ENGINE WIRING HARNESS

1

A32CCQA

3

9

8

10

2

5

11

7

12

6

4

1. ECM

2. CTS connector

3. EGTS connector

4. Fuel injector connector (cylinder MAG side)

5. Ignition coil connector

6. Fuel injector connector (cylinder PTO side)

7. TPS connector

8. ATS connector

9. Engine connector

10. APS connector

11.KS connector

12. CPS connector

NOTE: Check if wiring harness shows any signs

of scoring.

Resistance Test

Check continuity of the circuits according to the

wiring diagram in the WIRING DIAGRAMS section

of this manual.

If wiring harness is good, check the respective

sensor/actuator as described in this section.

Otherwise, repair the connectors, replace the

wiring harness or the ECM as diagnosed.

Removal

Remove air intake silencer.

Disconnect the wiring harness from all sensors/

actuators.

Disconnect the connector from the ECM.

Cut all locking tie which are holding the wiring har-

ness in position.

Remove complete wiring harness.

Installation

First connect the connector A to the ECM and the

engine connector to the vehicle wiring harness.

Reconnect the wiring harness to all sensors/actu-

ators and reinstall all locking tie that have been re-

moved.

Install all remaining parts, which have been re-

moved.

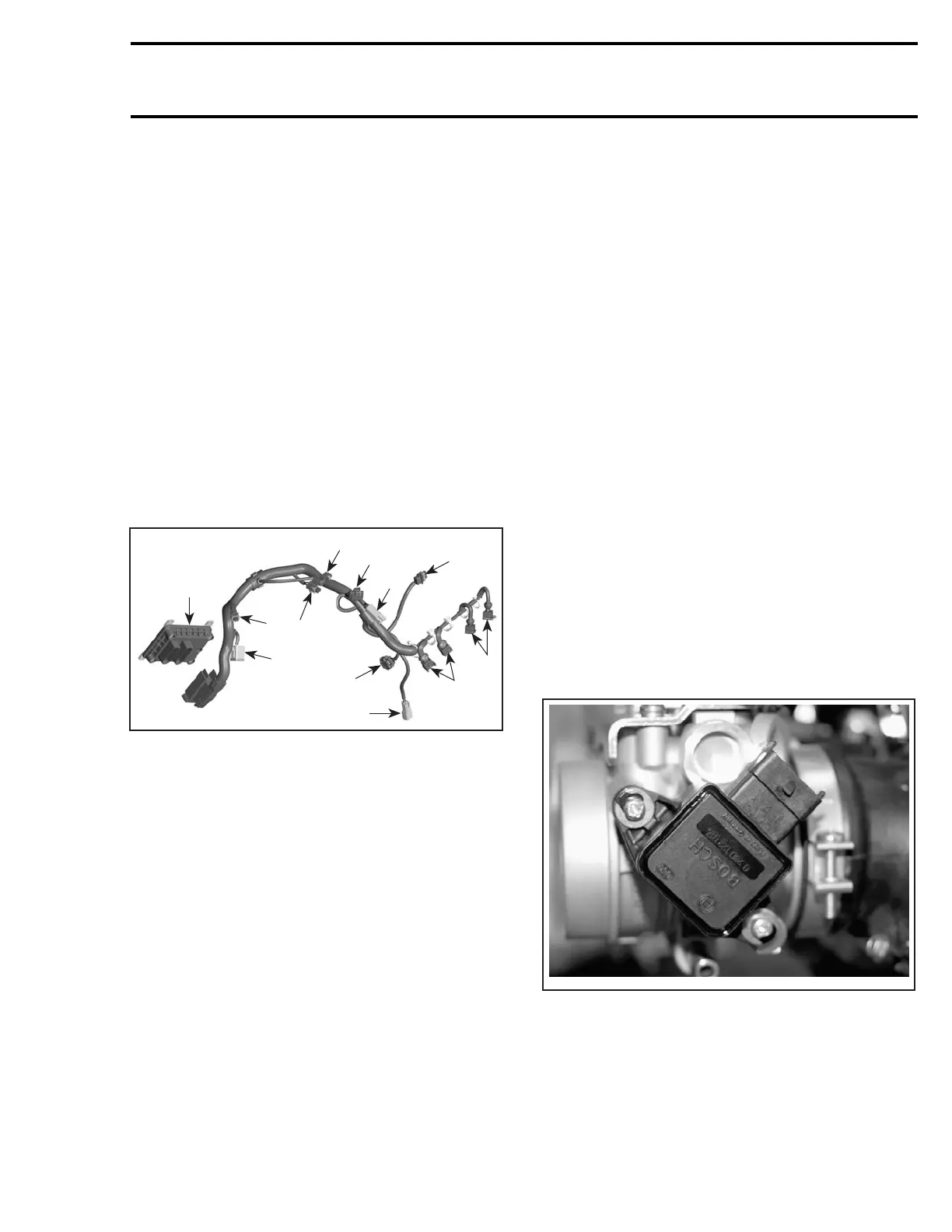

THROTTLE POSITION SENSOR

(TPS)

General

The throttle position sensor (TPS) is a potentiome-

ter that sends a signal to the ECM which is propor-

tional to the throttle shaft angle.

A32C9RA

THROTTLE POSITION SENSOR (TPS)

IMPORTANT: Prior to testing the TPS, ensure

that mechanical components/adjustments are

adequate according to THROTTLE BODY in AIR

INDUCTION SYSTEM above.

mmr2004-Rev 189

Loading...

Loading...