Section 06 TRANSMISSION

Subsection 06 (CHAINCASE)

REMOVAL AND DISASSEMBLY

To remove chaincase proceed as follows.

Remove battery and battery rack (if so equipped)

to gain access, refer to BATTERY section.

Remove hair pin no. 8. Release drive chain ten-

sion by unscrewing tensioner adjustment screw.

Drain oil by removing drain plug no. 24.

3,4,5,6,13,16,17, Cotter Pin, Nut,

Sprocket, Shim and Drive Chain

Apply parking brake.

Remove cotter pin no. 3 and nut no. 4 retaining

upper sprocket no. 5 and screw no. 15 retaining

lower sprocket no. 16. Pull sprockets and drive

chain simultaneously. Remove shims no. 6 and

no. 17.

NOTE: Should countershaft removal be required,

refer to BRAKE then look for COUNTERSHAFT

REMOVAL.

Release parking brake.

Remove3nutsno. 14.

Unfold locking tab no. 23 then remove caliper re-

taining screws no. 22.

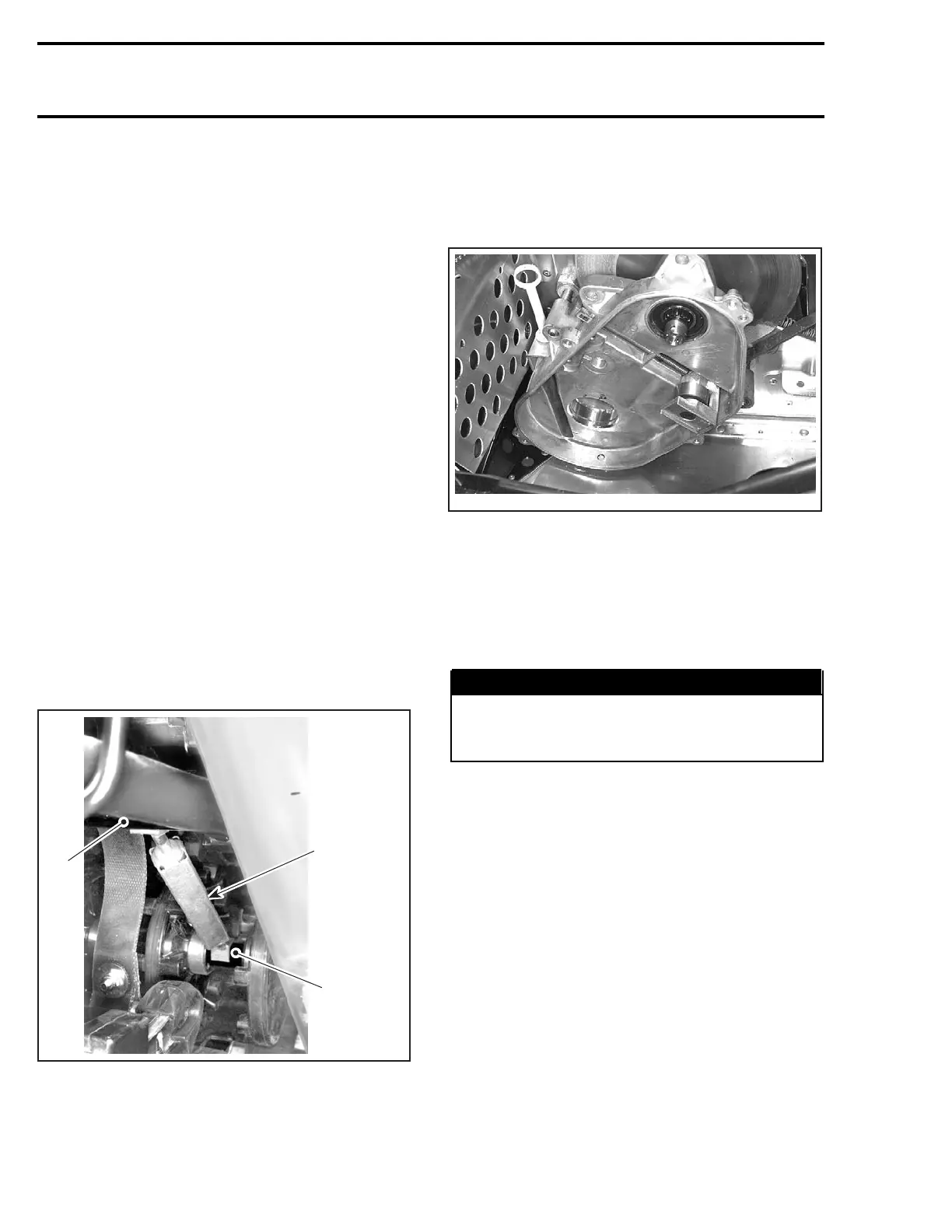

Release track tension, use drive axle holder no. 20

(P/N 529 007 200).

A32D0LA

2

529 007 200

1

TYPICAL

1. Drive axle

2. Suspension front arm upper axle

Pry out drive axle oil seal no. 19 from chaincase.

Pull chaincase from drive axle and countershaft.

Using 2 large prybars inserted between chaincase

housing no. 7 and frame, pry complete assembly

from vehicle.

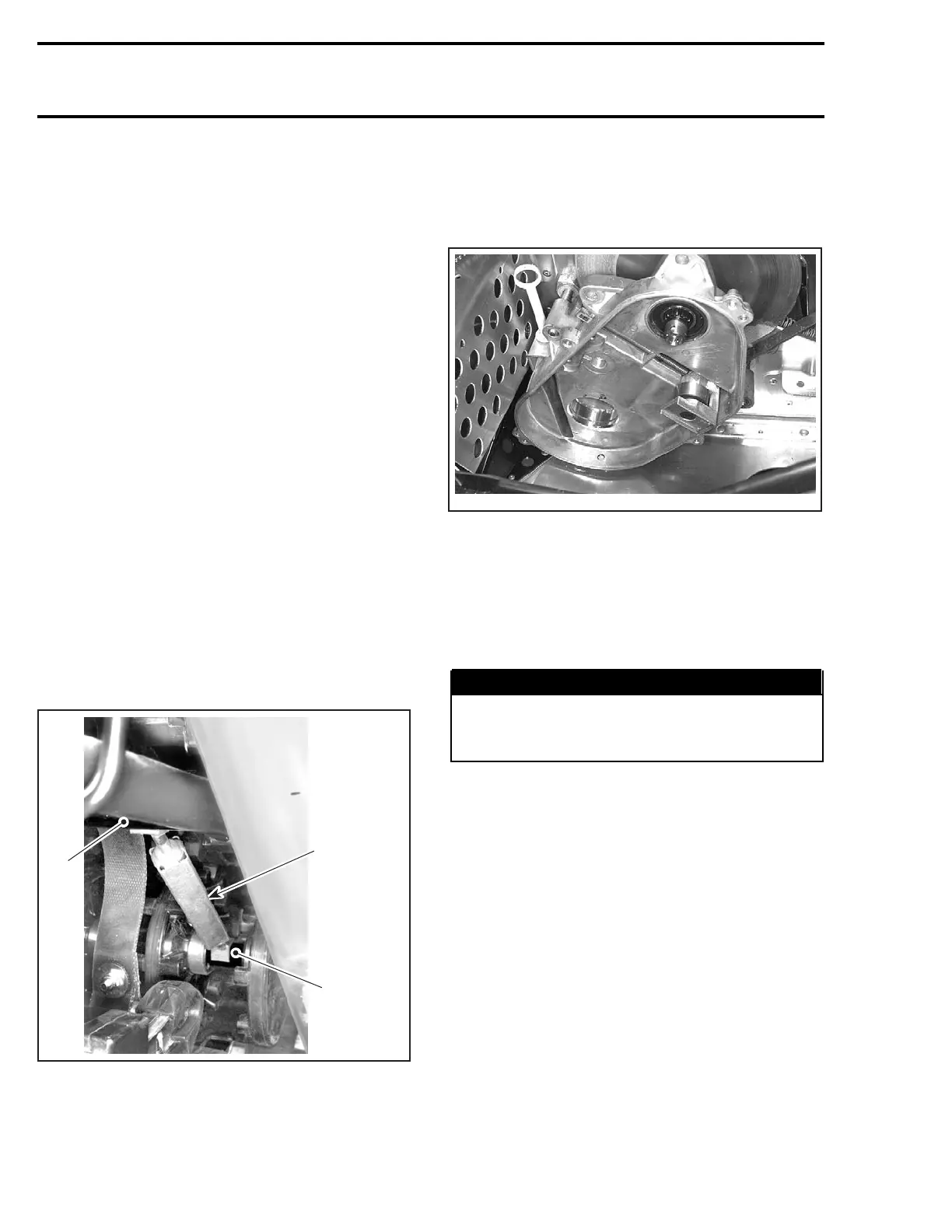

A32D0KA

TYPICAL — CHAINCASE HOUSING REMOVAL

INSPECTION

Visually inspect the chain for cracked, damaged or

missing links. Check for worn or defective bear-

ings, sprockets and chain tensioner components.

WARNING

If chain deflection is greater than 38 mm

(1.5 in) (without chain tensioner), replace

chain and check condition of sprockets.

GEAR RATIO MODIFICATION

For particular applications, the number of teeth of

the sprockets can be increased or decreased on

lower and upper sprockets.

Refer to TECHNICAL DATA for gear ratios.

CAUTION: Gear ratio modifications should

only be performed by experienced mechanics

since they can greatly affect vehicle perfor-

mance.

NOTE: For high altitude regions, a service bulletin

will give information about calibration according to

altitude.

246 mmr2004-Rev

Loading...

Loading...