Section 07 ELECTRICAL SYSTEM

Subsection 05 (TESTING PROCEDURE)

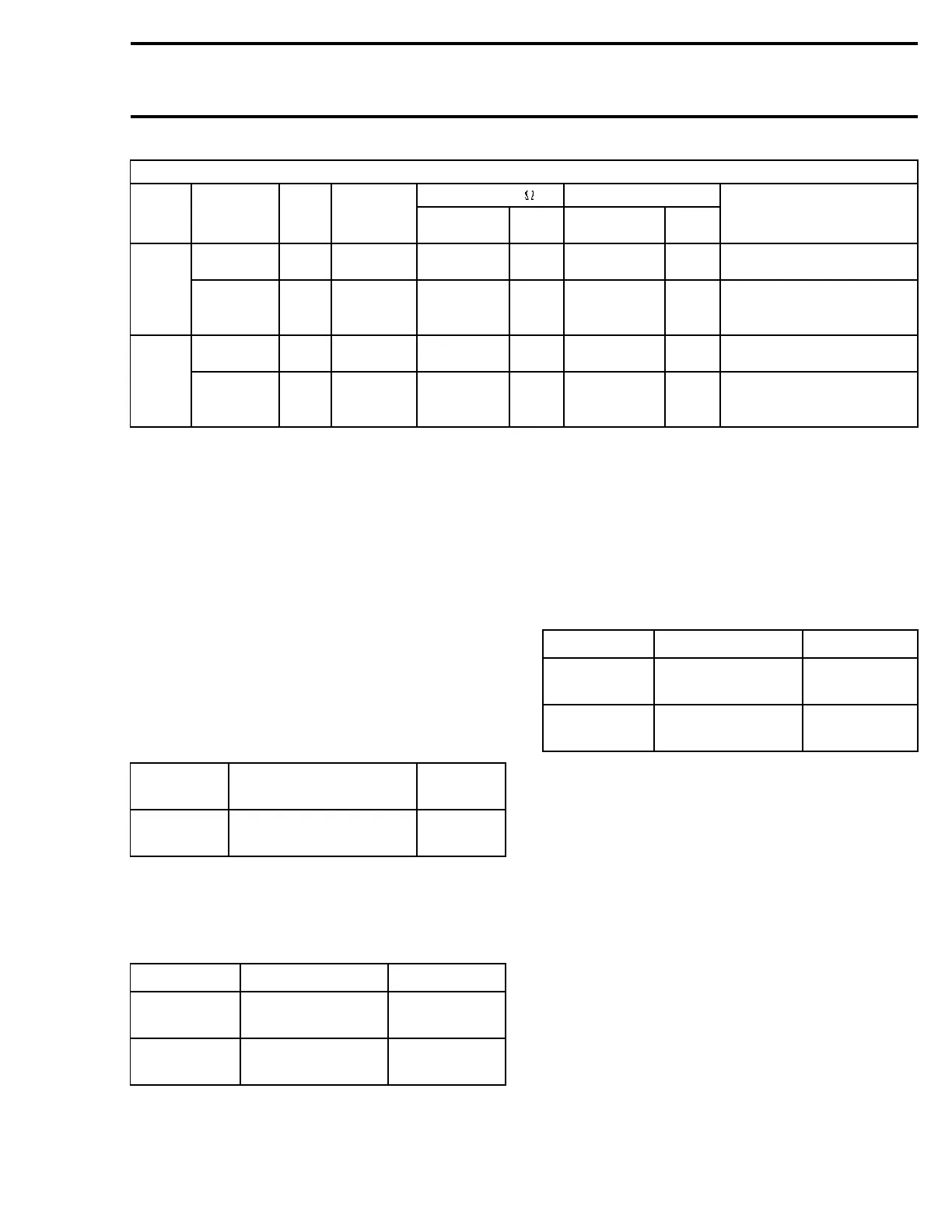

360 W MODEL (ignition and electrical system testing)

RESISTANCE VOLTAGE V

PART

TEST TO BE

PERFORMED

WIRE

COLOR

MULTIMETER

PROBE

CONNECTION

MULTIMETER

SCALE

VALUE

(ohms)

MULTIMETER

SCALE

VALUE

(volt)

NOTE

Coil

WH/GN

and BK

5–RC-85–F

5–RC-86–F

— — 00.0 Vdc

10.5 to

13.5

Engine idling (1500 to 1800 RPM)

Relay (with

battery)

Contacts

RD/WH

and

RD/BR

5–RC-87–F

5–RC-30–F

— — 00.0 Vdc

00.0 to

0.10

Engine idling (1500 to 1800 RPM)

Coil

WH/GN

and BK

5–RC-85–F

5–RC-86–F

— — 00.0 Vdc

10.5 to

13.6

Engine idling (1500 to 1800 RPM)

Relay

(without

battery)

Contacts

RD/BU

and

RD/BR

5–RC-87–F

5–RC-30–F

— — 00.0 Vdc

00.0 to

0.11

Engine idling (1500 to 1800 RPM)

NOTE: If voltage is present at the coil and contact, replace the relay.

An approved automotive spark plug tester is preferred for testing the secondary winding voltage.

All cranking tests are performed with the manual starter. Faster cranking speeds may produce higher

voltages.

Ignition and electric starter will not work if the Engine stop switches is in the kill position.

Charging system test should be performed if a no spark condition is encountered on this vehicle.

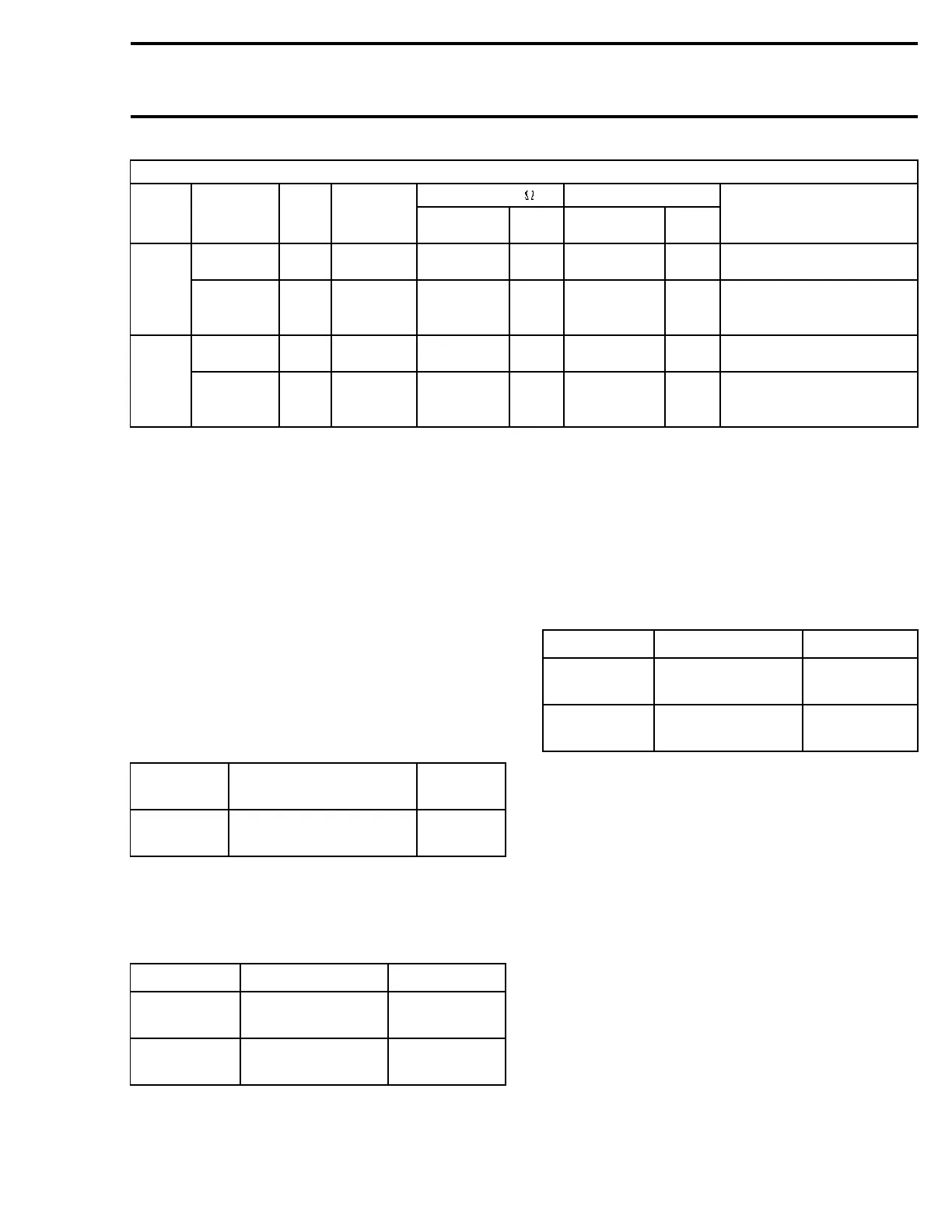

INSPECTION OF HEATING

ELEMENTS

NOTE: All measurements must be performed at

21°C(70°F).

Throttle Lever Heating Element

Current Measurement

HIGH

INTENSITY

BROWN wire

0.23 A

minimum

LOW

INTENSITY

BROWN /YELLOW wire

0.13 A

minimum

Handlebar Grip Heating Element

Resistance Measurement

All Models except SDI

INTENSITY WIRES OHMS

HIGH

BLACK and

ORANGE/VIOLET

13.7 to 16.7*

LOW

BLACK and

ORANGE

6.8to8.4*

SDI Models

INTENSITY WIRES OHMS

HIGH

BLACK and

ORANGE/VIOLET

17 to 23.5*

LOW

BLACK and

ORANGE

8.5 to 11.8*

*When measuring resistance at terminals the ac-

tual value will be half the measurement in table.

The reason for that is the elements are connected

in parallel. Therefore the total resistance is half

the resistance of one element.

mmr2004-Rev 283

Loading...

Loading...