Section04ENGINE

Subsection 08 (FUEL TANK AND FUEL PUMP)

NOTE: The following instructions are not applica-

ble on SDI models. See COMPONENT INSPEC-

TION AND ADJUSTMENT concerning fuel pump

procedure on these models.

REMOVAL

Remove air intake silencer and carburetors.

NOTE: Do not disconnect cables from carbure-

tors.

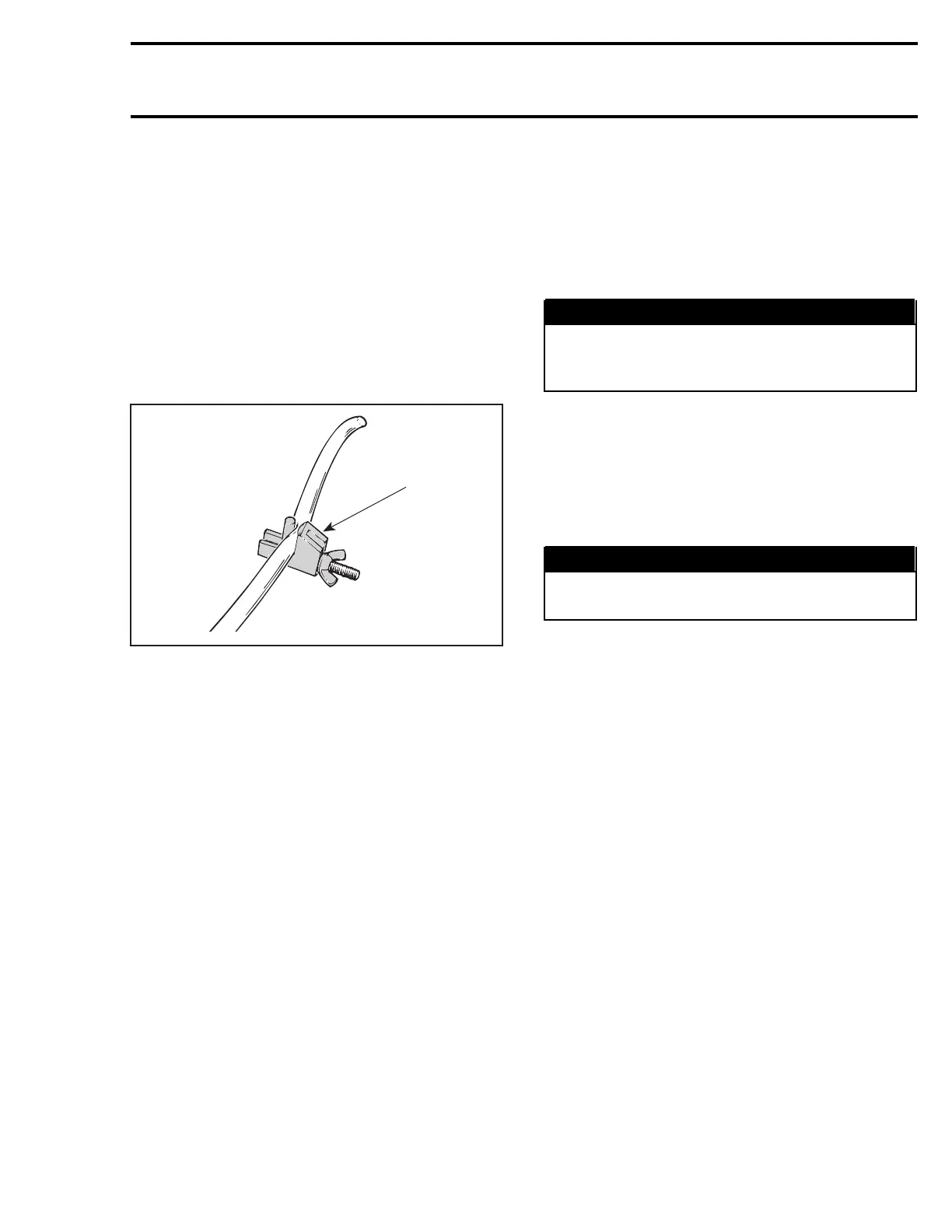

Install a hose pincher (P/N 295 000 076) on fuel

supplylineclosetopumpinlet.

A01B2JA

295 000 076

Disconnect fuel outlet line(s).

Disconnect impulse line.

Remove screws securing fuel pump to chassis.

PUMP VERIFICATION

Check fuel pump valves operation as follows:

Connect a clean plastic tubing to the inlet nipple

and alternately apply pressure and vacuum with

pump of leak test kit. The inlet valve should re-

lease with pressure and hold under vacuum.

Repeat the same procedure at the outlet nipple.

This time the outlet valve should hold with pres-

sure and also under vacuum.

NOTE: Plug remaining outlet with finger while

checking outlet valve.

Check impulse diaphragm and gasket on fuel

pump with twin outlets as follows:

Connect a clean plastic tubing to the impulse nip-

ple and plug vent hole on top cover on so equipped

models. Either apply pressure or vacuum. The di-

aphragm/gasket must not leak.

CLEANING AND INSPECTION

The entire pump should be cleaned with general

purpose solvent before disassembly.

Fuel pump components should be cleaned in gen-

eral purpose solvent and dried with compressed

air.

WARNING

Solvent with low flash point such as gasoline,

naphtha, benzol, etc, should not be used as

each is flammable and explosive.

Inspect diaphragm. The pumping area should be

free of holes, tears or imperfections. Replace as

needed.

INSTALLATION

Inverse removal procedure.

WARNING

Pressure test to ensure there is no leak in fuel

system.

mmr2004-Rev 163

Loading...

Loading...