Section 06 TRANSMISSION

Subsection 03 (DRIVEN PULLEY)

DRIVEN PULLEY BUSHING WEAR LIMIT

mm (in)

Small bushing 38.30 (1.508)

Large bushing 108.2 (4.260)

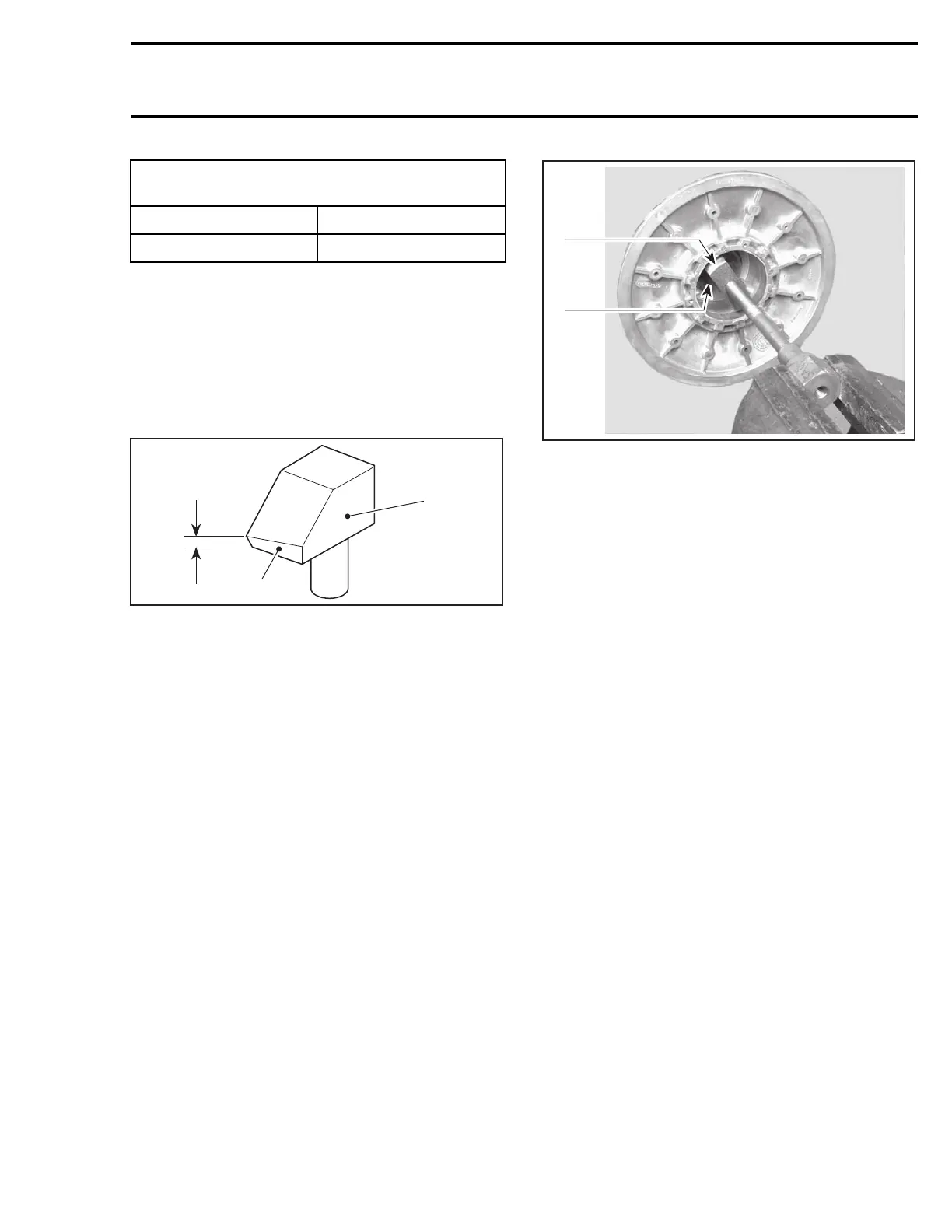

Slider Shoe

Black slider shoe = forward.

Red slider shoe = reverse.

Check cam slider shoes no. 10 and no. 11 for

wear. Replace when inside edge thickness of cam

slider shoe slope base is worn to 1 mm (.039 in)

or less.

2

1

A15D0OA

3

1. Measure thickness of slope base here

2. Sliding pulley side

3. Slope base

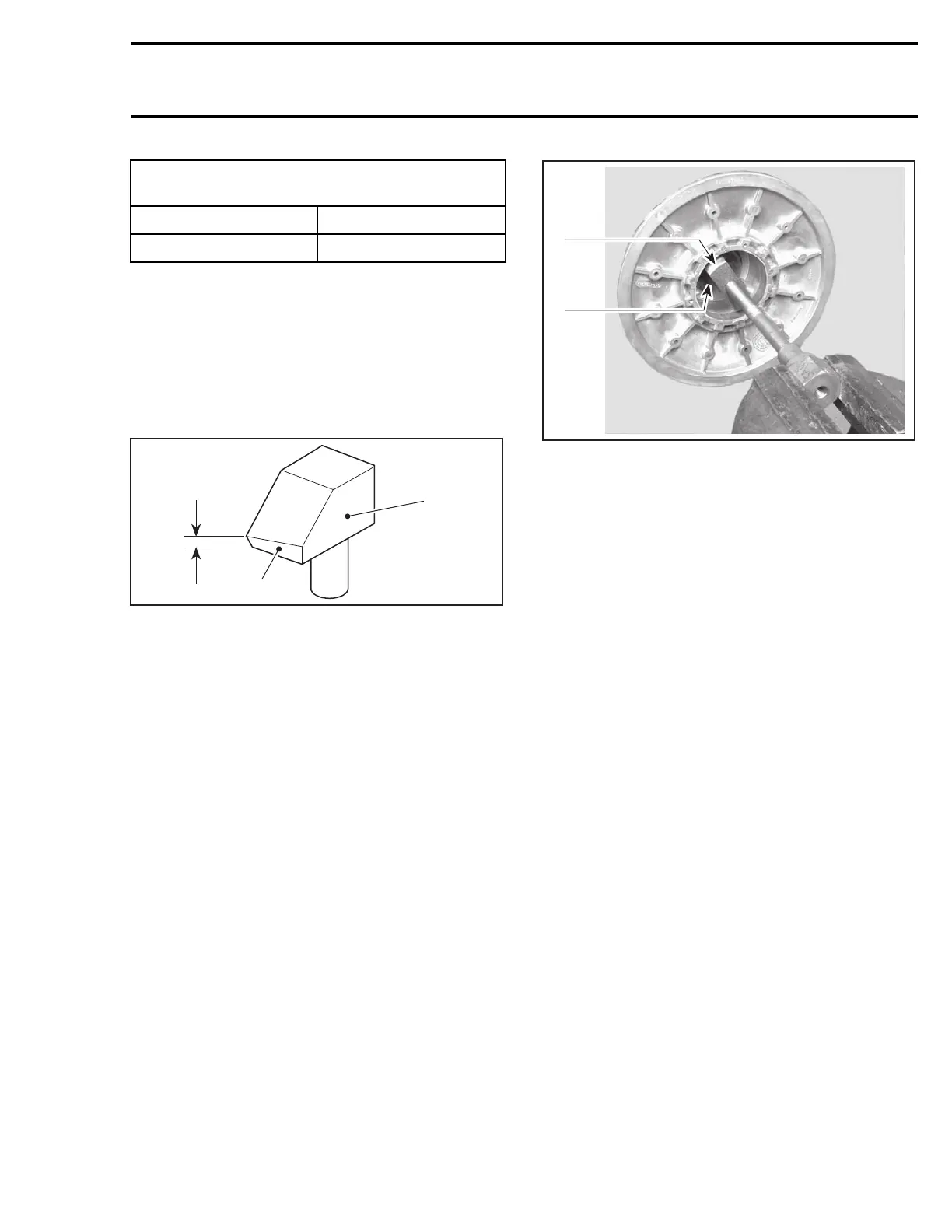

BUSHING REPLACEMENT

Large Bushing

Remove Allen screws if applicable. Heat to break

Loctite bond.

Install support plate included in tool (P/N 529 031

100) inside sliding half.

Place extractor (P/N 529 035 575) below bushing.

A03D1WB

2

1

TYPICAL

1. Support plate

2. Extractor

Mount screw head of new puller (P/N 529 035

524) in a vise.

Turn pulley half by hand to extract old bushing.

Before bushing installation, file sliding half bore to

remove burrs from crimping areas.

Coat bushing outside diameter with Loctite 609

(P/N 413 703 100). Place new bushing on sliding

half and slightly tap to engage squarely the bush-

ing in the sliding.

ASSEMBLY

Cam Slider Shoe

When replacing slider shoes no. 10 and no. 11,al-

ways install a new set (3 shoes) to maintain equal

pressure on the cam.

Install slider shoes as per following photo. Red

slider shoes are being used for reverse and black

ones for forward.

mmr2004-Rev 229

Loading...

Loading...