Section 07 ELECTRICAL SYSTEM

Subsection 04 (ELECTRIC STARTER)

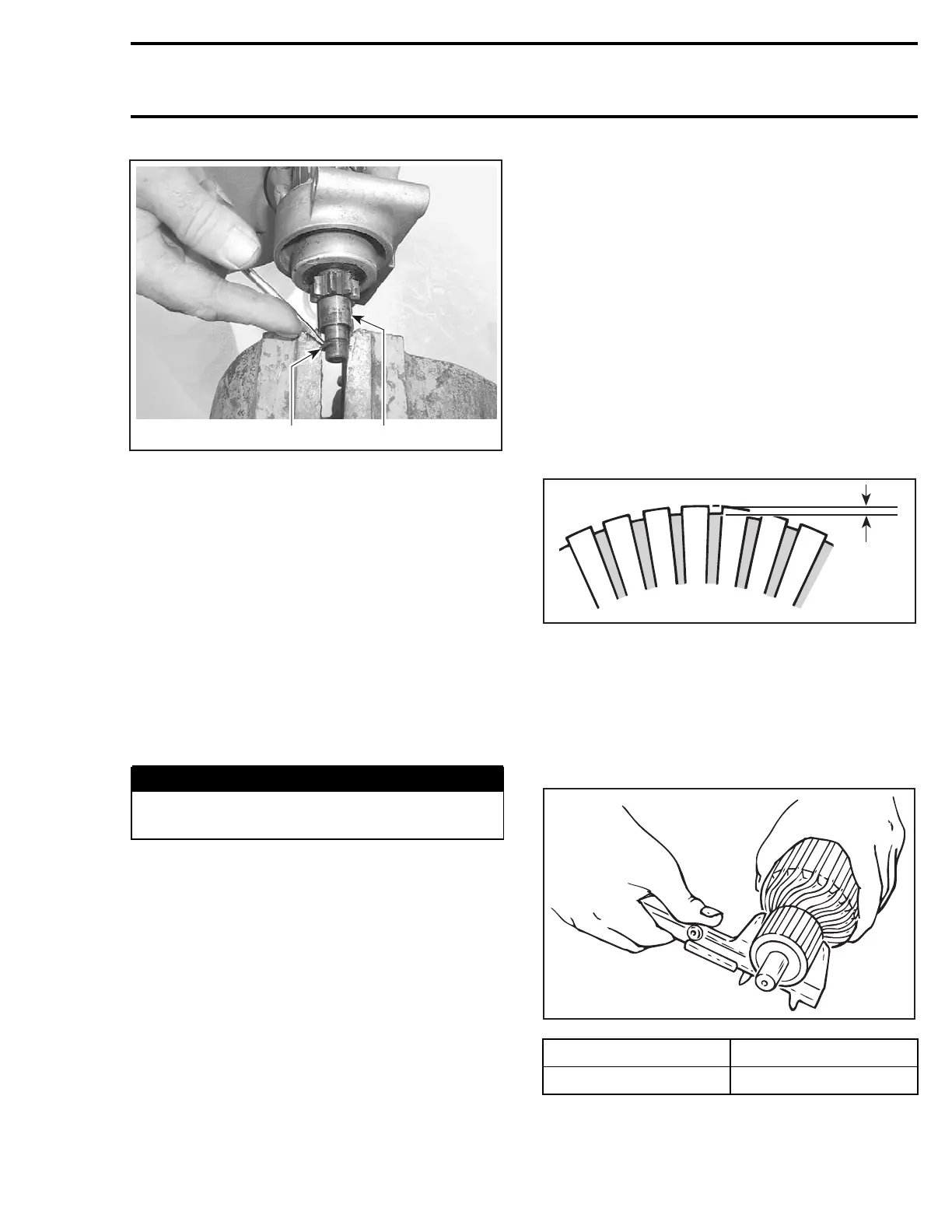

A32E20A

2

1

1. Collar

2. Snap ring

Turn starter clutch no. 6 clockwise to remove it

from armature assembly no. 11.

Pull housing from armature.

CLEANING

CAUTION: Yoke assembly and drive unit as-

sembly must not be immersed in cleaning sol-

vent.

Clean brushes and holders with a clean cloth

soaked in solvent. Brushes must be dried thor-

oughly with a clean cloth.

Blow brush holders clean using compressed air.

WARNING

Always wear safety glasses when using com-

pressed air.

Remove dirt, oil or grease from commutator using

a clean cloth soaked in suitable solvent. Dry well

using a clean and dry cloth.

Clean engine ring gear teeth and drive unit (clutch).

NOTE: Bushings or bearings must not be cleaned

with grease dissolving agents.

Immerse all metal components in cleaning solu-

tion. Dry using a clean and dry cloth.

INSPECTION

All Models except 4-Tec Engines

Armature

NOTE: An ohmmeter may be used for the follow-

ing testing procedures, except for the one con-

cerning the shorted windings in the armature.

Check the commutator for roughness, burnt or

scored surface. If necessary, turn the commuta-

tor on a lathe, enough to remove grime only.

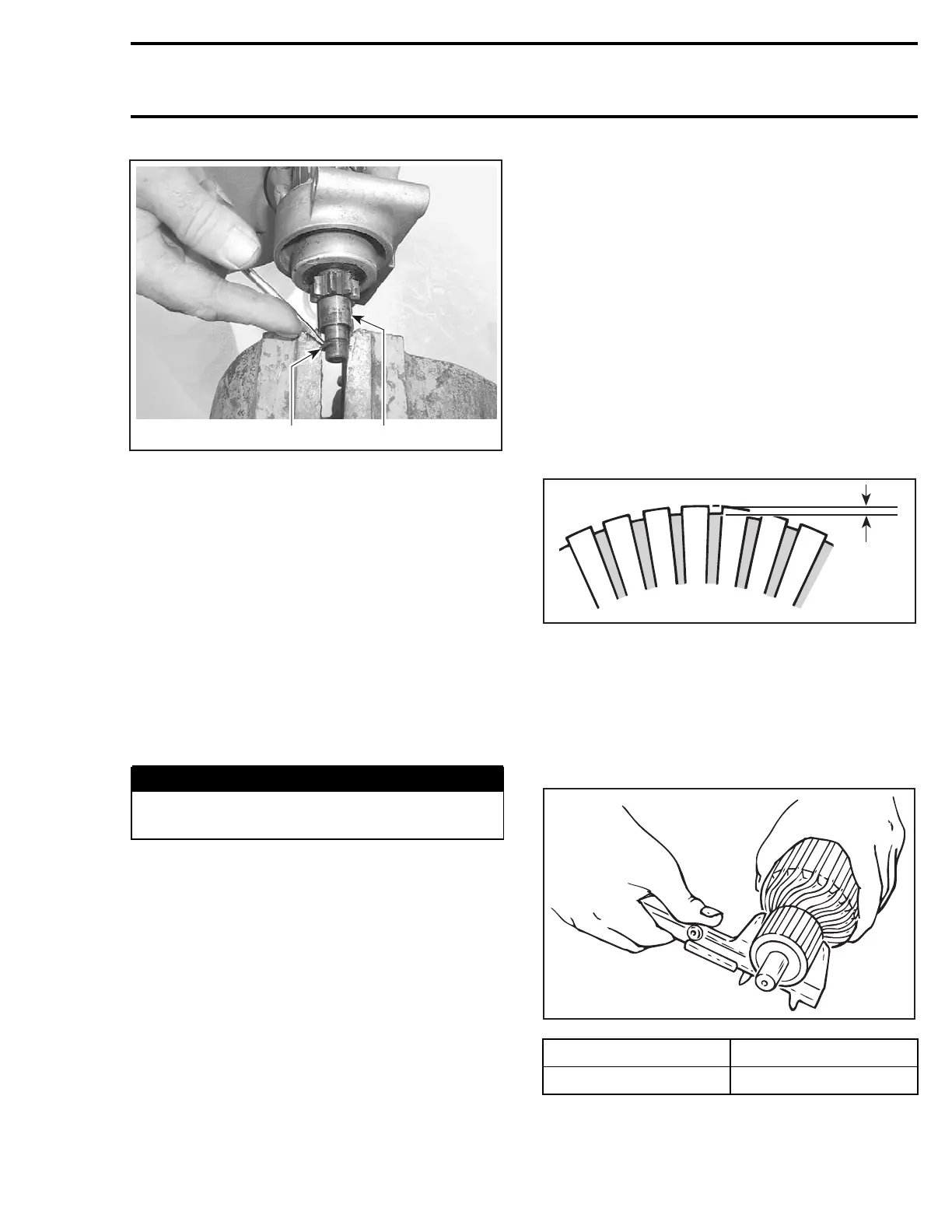

Check the commutator for mica depth. If the

depth is less than 0.20 mm (.008 in), undercut

the mica. Be sure that no burrs are left and no

copper dust remains between the segments after

the undercutting operation is completed.

F01H0RA

1

1. Commutator undercut 0.20 mm (.008 in)

Check the commutator out-of-round condition

with V Blocks and an indicator. If the commutator

out-of-round is more than 0.40 mm (.016 in), the

commutator should be turned on a lathe.

Check commutator outer diameter. If less than

specified value, replace.

A03E06A

MODEL WEAR LIMIT

All models 27 mm (1.063 in)

mmr2004-Rev 265

Loading...

Loading...