Section04ENGINE

Subsection 01 (593, 593 HO, 593 HO SDI AND 793 HO ENGINE TYPES)

Maintenance

All Models

There are no wear parts anywhere in the system

and there are no adjustments to be periodically

checked. The only possible maintenance required

wouldbecleaningofcarbondepositsfromthe

guillotine slide. Cleaning intervals would depend

upon the user’s riding style and the quality of the

oil used.

Bombardier suggests annual cleaning of the valve.

If a customer uses lower quality oil, than recom-

mended, more frequent cleaning may be required.

No special solvents or cleaners are required when

cleaning the valve.

On SDI models, check if solenoid heating ele-

ment is still functional once a year, the element

should be warm after one minute of riding. At the

same time, check if crankcase check valve is still

functional.

NOTE: Make sure hoses are not kinked or dam-

aged.

Boring Precaution

All Models

In its stock configuration, the RAVE valve guillo-

tine has a minimum of 0.5 mm (.020 in) clearance

to the cylinder bore measured at the center line

of the cylinder. This is the minimum production

clearance.

DISASSEMBLY

RAVE System

NOTE: RAVE stands for Rotax Adjustable Variable

Exhaust.

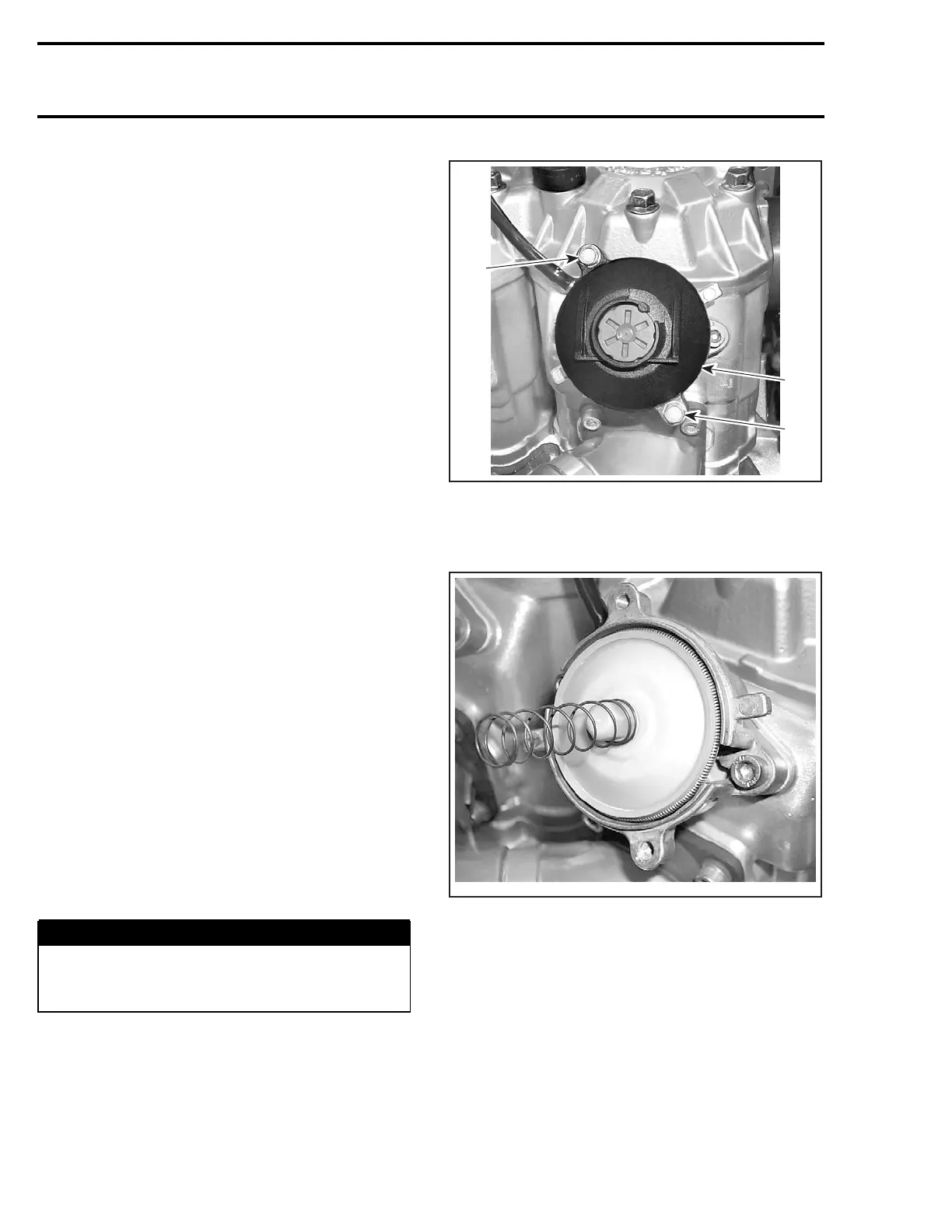

Remove RAVE valve cover no. 4 by removing

screws no. 5.

WARNING

Firmly hold cover to valve base no. 6. The

compression spring no. 7 inside the valve is

applying pressure against the cover.

2

A32C96A

1

2

TYPICAL

1. Cover

2. Retaining screws

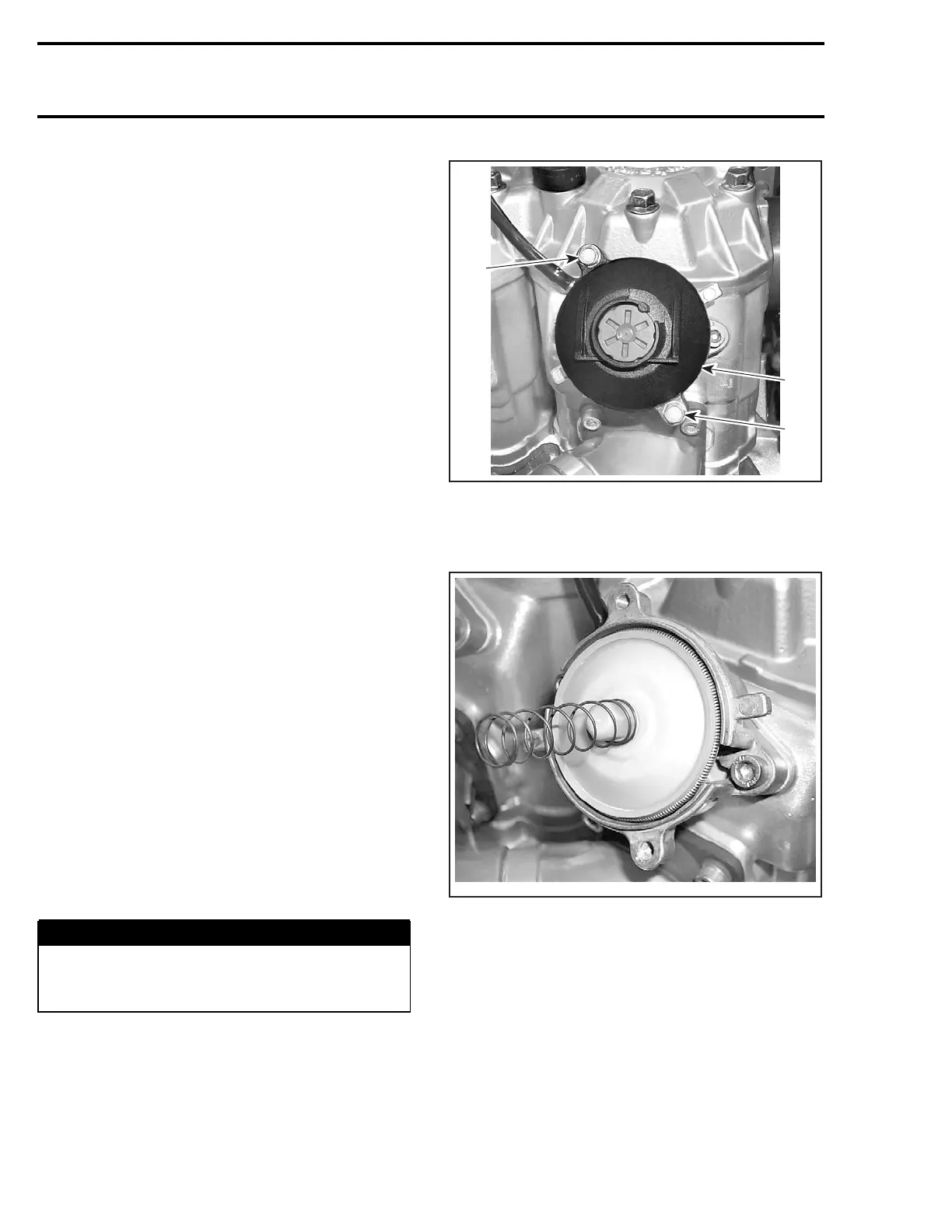

Remove the compression spring no. 7.

A32C97A

TYPICAL

Unscrew the Allen socket screw no. 8 then re-

move the RAVE valve base no. 6.

90 mmr2004-Rev

Loading...

Loading...