Section 07 ELECTRICAL SYSTEM

Subsection 04 (ELECTRIC STARTER)

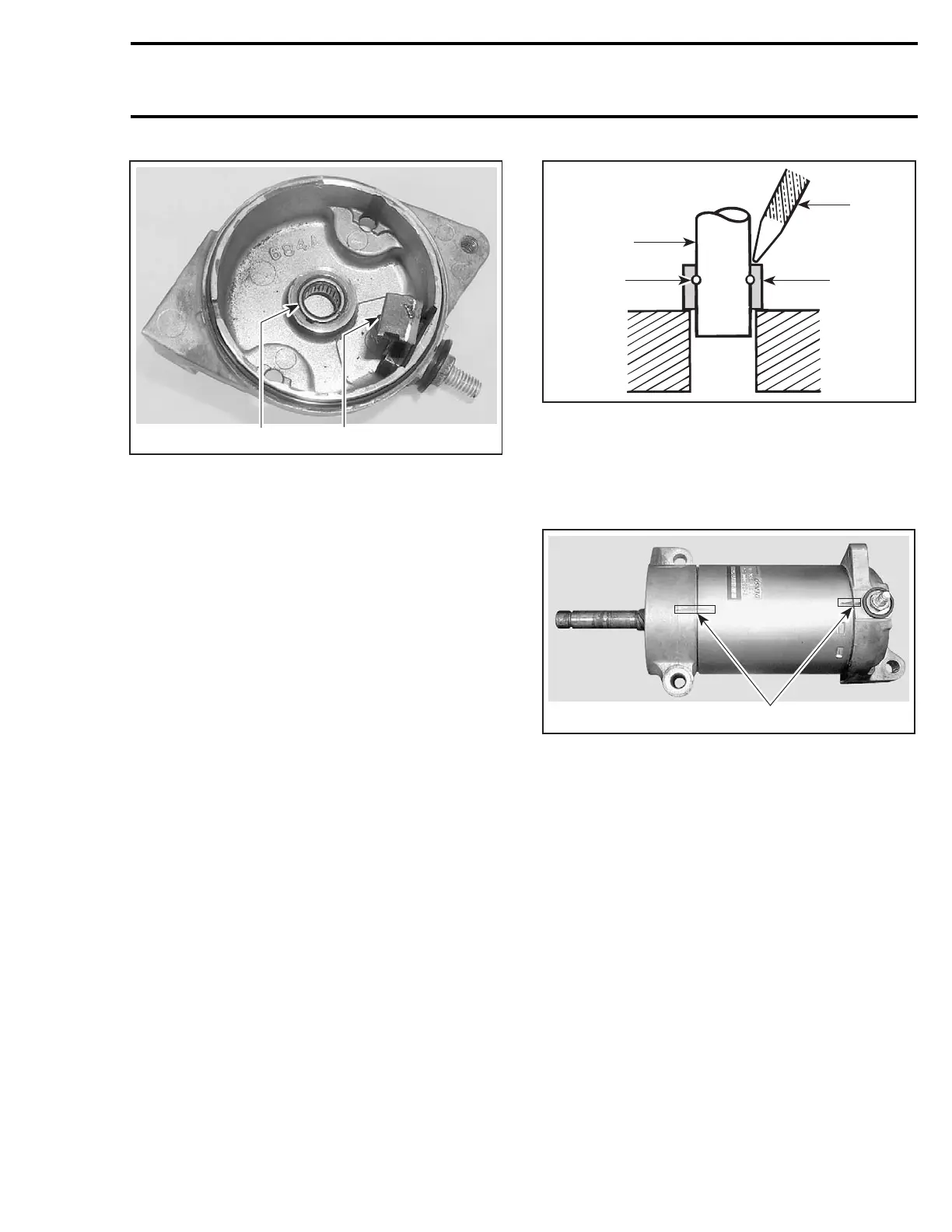

1

2

A32E22A

1. Roller bearing

2. Positive brush

Overrunning Clutch

The pinion of the overrunning clutch should turn

smoothly in a clockwise direction, and should not

slip in a counterclockwise direction. If defective,

replace.

Check the pinion teeth for wear and damage. If

defective, replace.

Relay

Inspect connections and clean as necessary. Re-

lay condition can be checked with an ohmmeter.

Install test probes on large connectors of relay

when it is activated (+ on RED/GREEN wire and

- on relay body for the fan cooled models and - on

the BLACK wire for liquid cooled models).

IMPORTANT: Nocurrentmustbepresentonlarge

cables when using ohmmeter, otherwise meter

could be damaged.

ASSEMBLY

Reverse the order of disassembly to reassemble

starter. However, attention should be paid to the

following operations.

Prior to assembling, coat sliding surfaces on arma-

ture shaft splines, overrunning clutch and bushing

with synthetic grease (P/N 413 711 500).

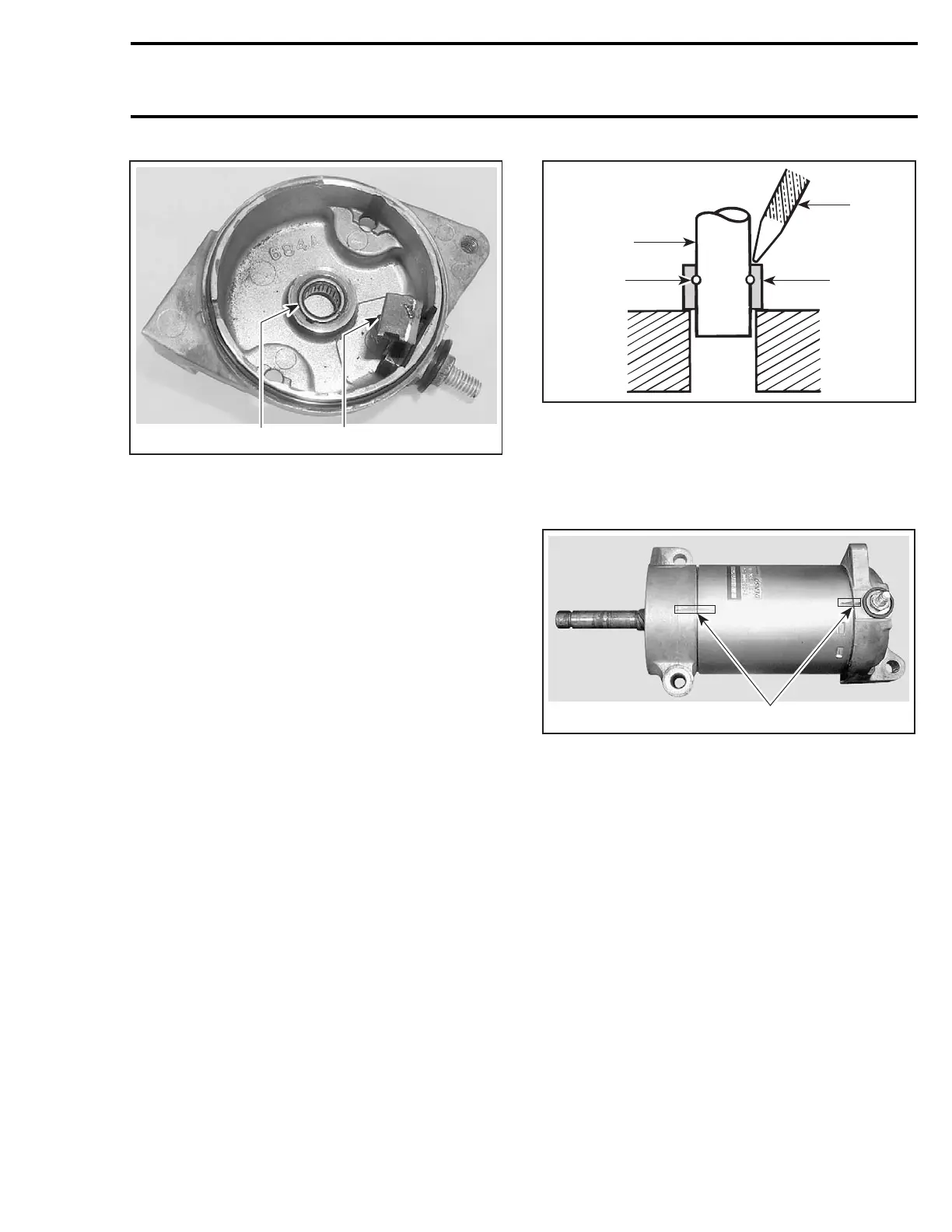

After placing collar no. 3 on armature shaft no. 11,

fit new snap ring no. 2 on armature shaft, then

make sure that it is properly secured.

Slide collar no. 3 over snap ring no. 2 and secure

in place by punching it at two or three places.

A03E0EA

1

2

4

3

1. Armature shaft

2. Snap ring

3. Collar

4. Punch

Starter Housing Assembly and Starter Housing

Align previously traced indexing marks.

1

A32E21A

TYPICAL

1. Aligned indexing marks

Open brushes and slide over commutator.

Align end frame locating notch with yoke locating

protrusion and properly sit brush holder no. 13 into

housing no. 14.

mmr2004-Rev 267

Loading...

Loading...