Section04ENGINE

Subsection 02 (ENGINE LEAK TEST AND DIMENSION MEASUREMENT)

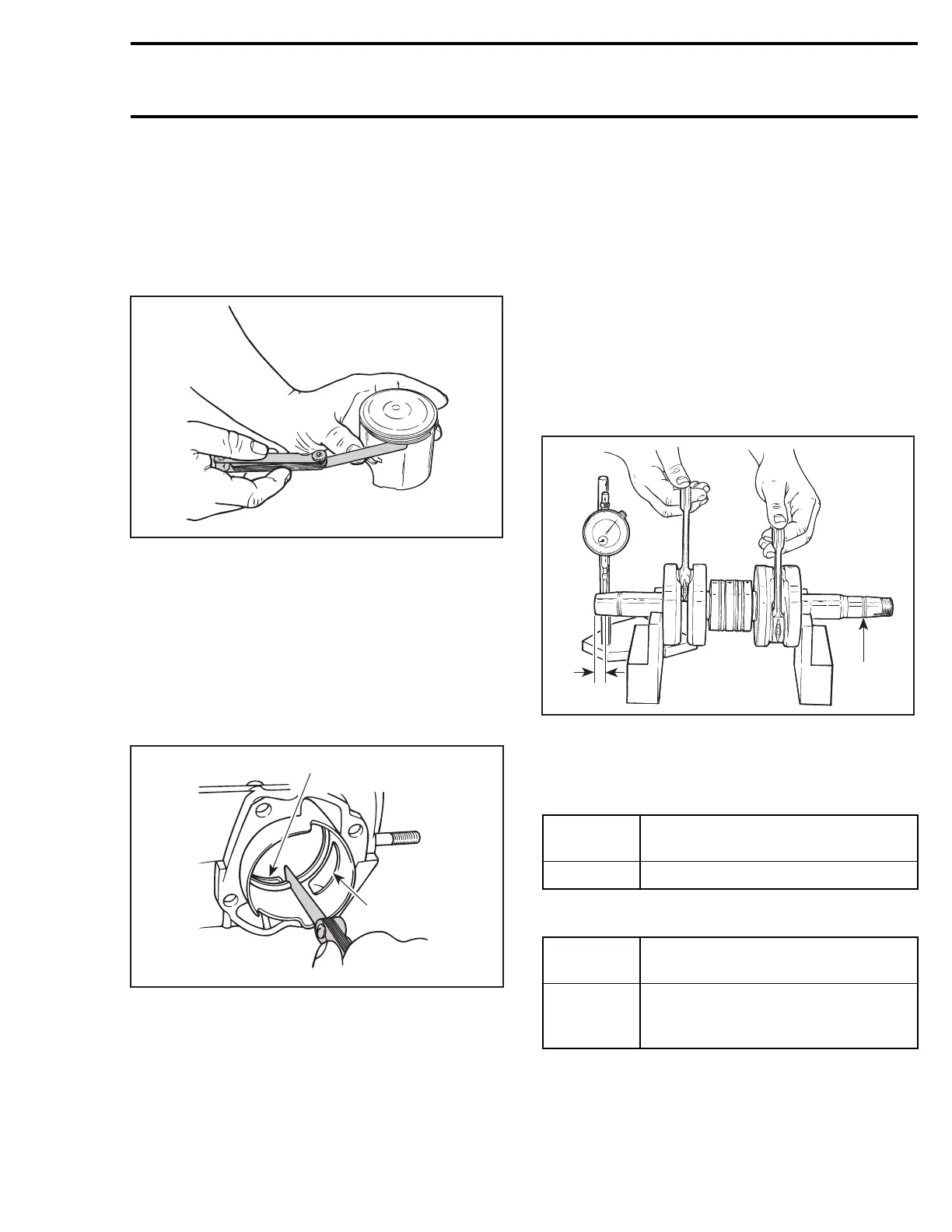

RING/PISTON GROOVE

CLEARANCE

Using a feeler gauge check clearance between

rectangular ring and groove. Replace piston if

clearance exceeds specified tolerance. Refer to

TECHNICAL DATA.

A01C0PA

RING END GAP

Position ring half-way between transfer ports and

intake port.

NOTE: In order to correctly position the ring in the

cylinder, use piston as a pusher.

Using a feeler gauge, check ring end gap. Replace

ring if gap exceeds specified tolerance. Refer to

TECHNICAL DATA.

A01C0QA

2

1

1. Transfer port

2. Intake port

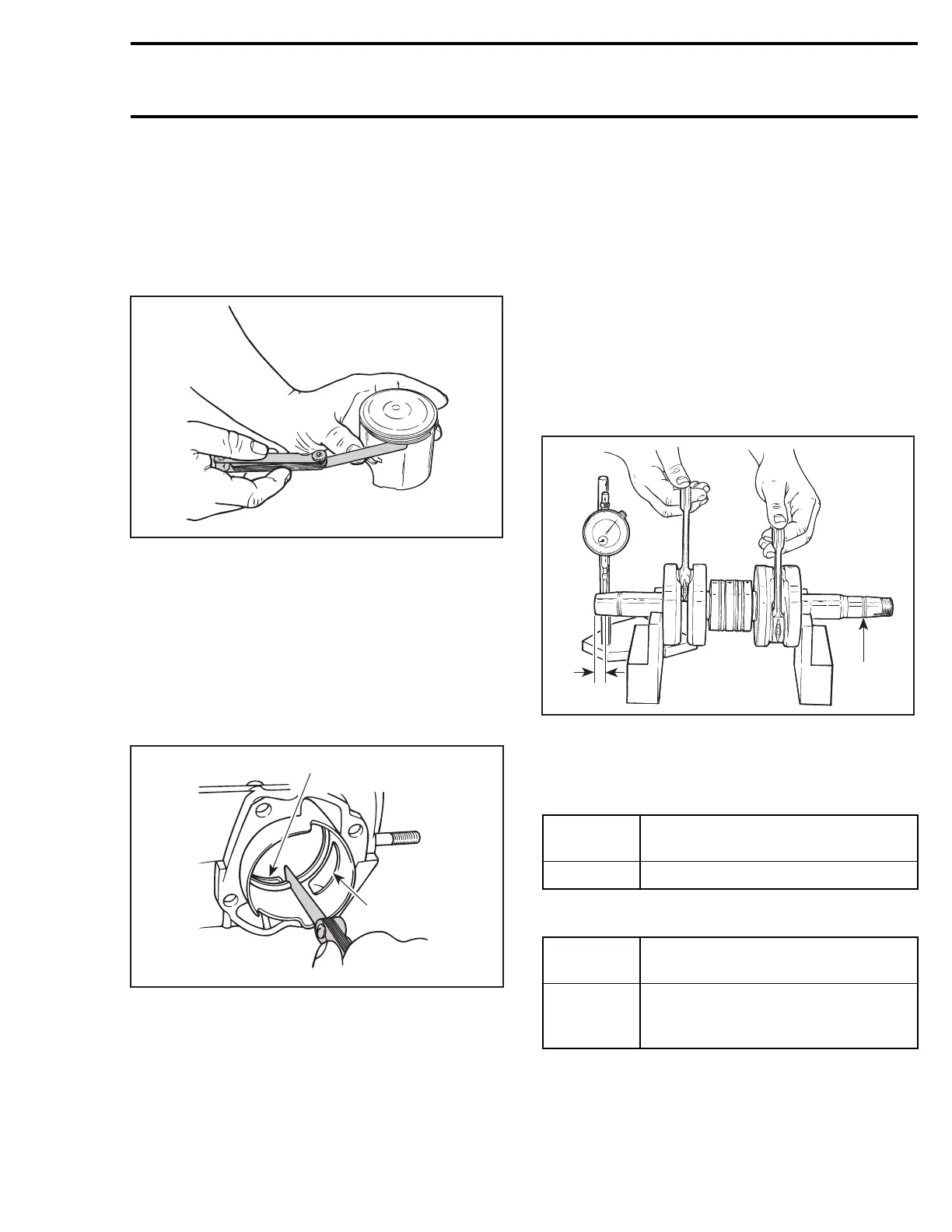

CRANKSHAFT DEFLECTION

Crankshaft deflection is measured with a dial indi-

cator.

Measuring (in crankcase)

First, check deflection with crankshaft in

crankcase. If deflection exceeds the specified tol-

erance, recheck deflection using V-shaped blocks

to determine the defective part(s). See below.

Measuring (on bench)

Once engine is disassembled, check crankshaft

deflection on V-shaped blocks. If deflection

exceeds the specified tolerance, it can be worn

bearings or a bent crankshaft. Remove crankshaft

bearings and check deflection again on V-shaped

blocks to determine the defective part(s). See

measurement A in following illustration.

A01C0RD

1

A

TYPICAL

1. Measure at mid point between the key and the first thread

A. 3mm(1/8in)

Crankshaft Deflection on PTO Side

ENGINE

TYPE

MAXIMUM ON PTO SIDE

mm (in)

All 0.06 (.0024)

Crankshaft Deflection on MAG Side

ENGINE

TYPE

MAXIMUM ON MAG SIDE

mm (in)

593, 593

HO/SDI,

793 HO

0.05 (.002)

mmr2004-Rev 119

Loading...

Loading...