Section 08 REAR SUSPENSION

Subsection 01 (SC-10 SUSPENSION)

Renew if any faults are present.

All Models Equipped with Gas

Pressurized Shock

NOTE: Gas pressurized shocks are light gray or

purple painted, or bare aluminum.

Gas shock can be inspected as follows:

Because of gas pressure, strong resistance is felt

when compressing shock. When released, the

shock will extend unassisted. Renew as required.

If suspecting an internal gas leak between oil

chamber and gas chamber, check shock as fol-

lows:

Install shock in a vise clamping on its bottom eye-

letwithitsrodupward.

Letitstandfor5minutes.

Completely push down the shock rod then re-

lease. Rod must come out at a steady speed. If

speed suddenly increases particularly at end of

extension, replace shock.

All Types of Shocks

If suspecting a frozen shock proceed as follows:

Place shock in a freezer (temperature below 0°C

(32°F)) for 4 hours. Push down on rod and note

its resistance, compare to a new shock. If shock

is frozen it will be impossible to compress.

INSTALLATION

Install assembled suspension into track with front

portion first.

Insert rear section of suspension into track.

Bolt front arm, rear arm then center top idler wheel

axle.

Adjust track tension.

RIDE ADJUSTMENT

Refer to Operator’s Guide.

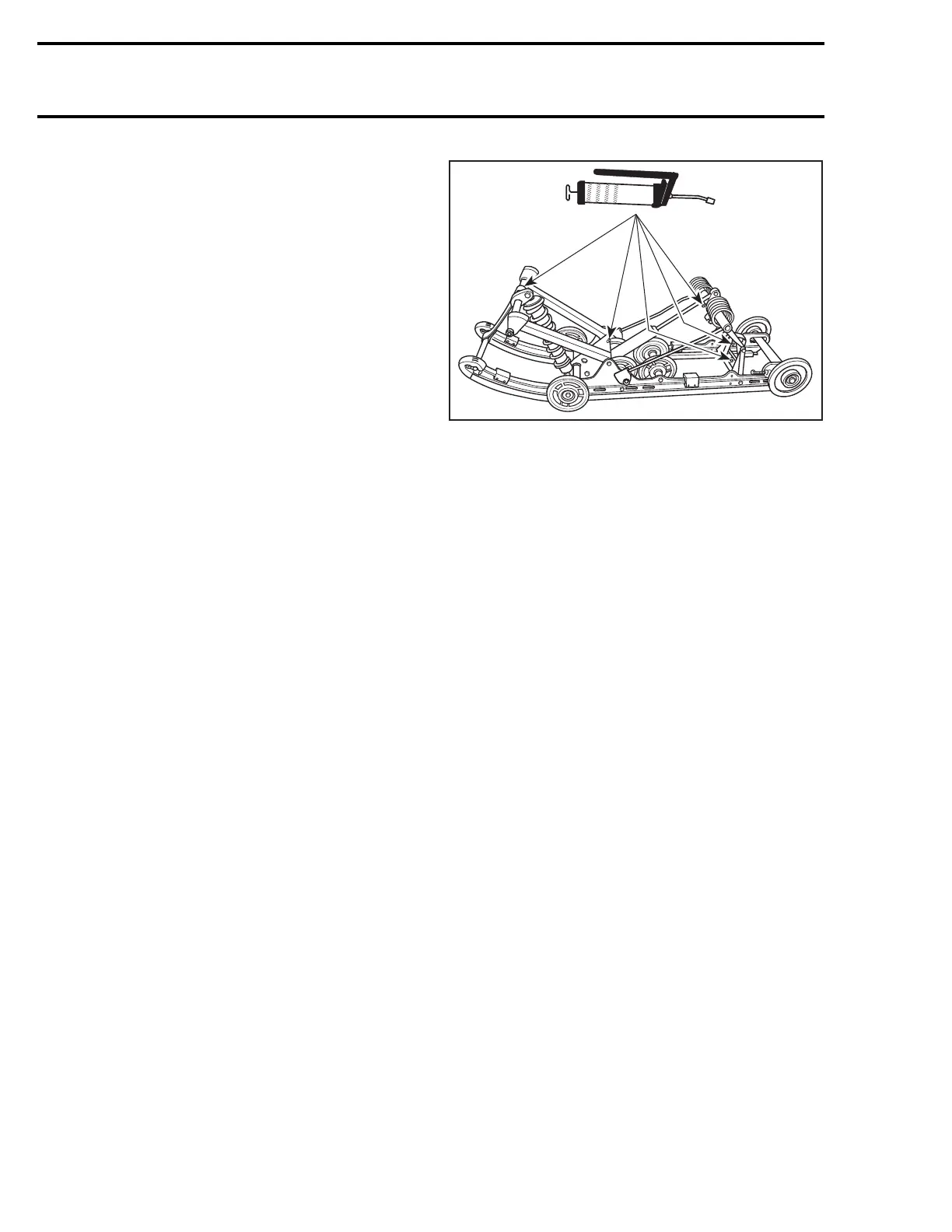

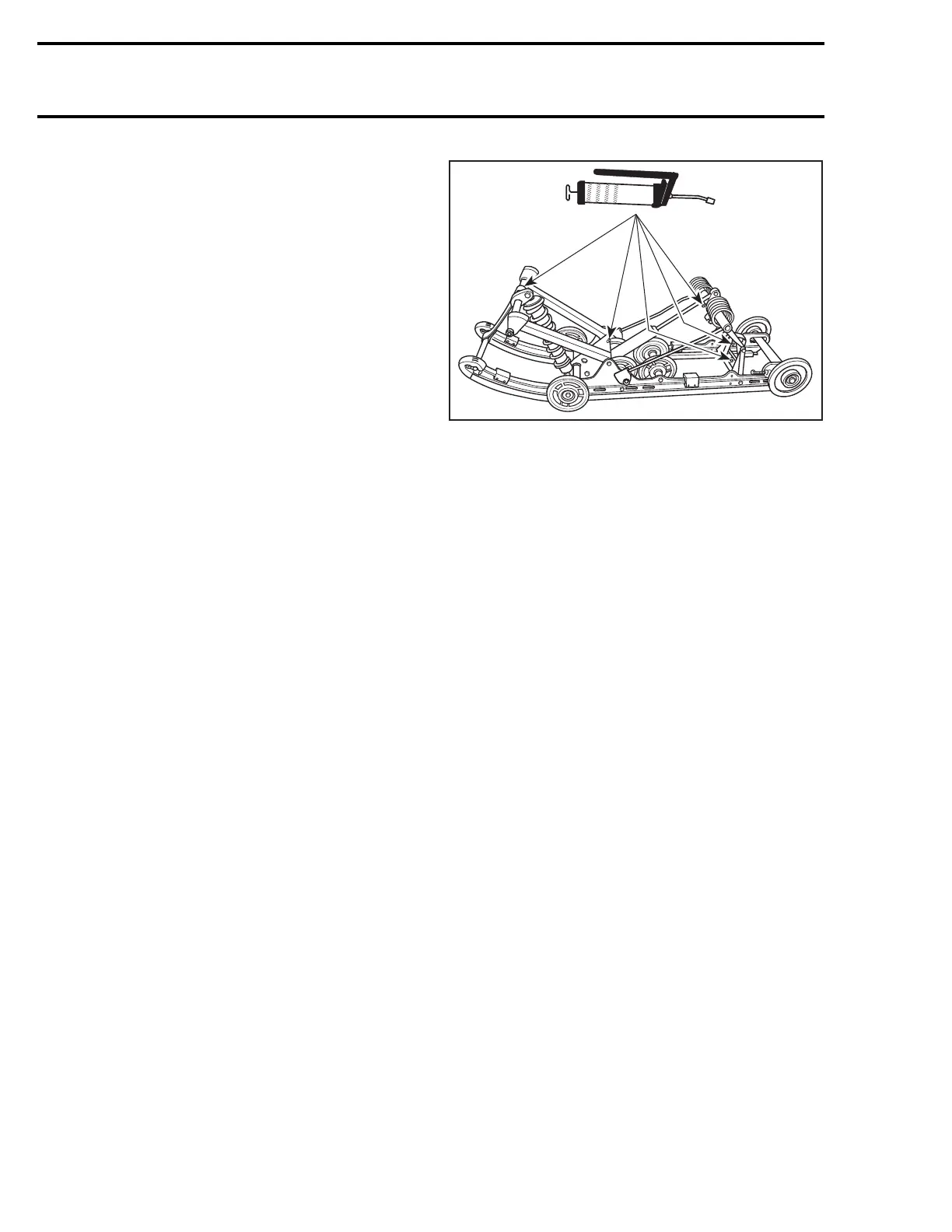

LUBRICATION

Lubricate front and rear arms at grease fit-

tings using suspension synthetic grease

(P/N 293 550 033).

A03F10C

SC-10: 5 GREASE FITTINGS

292

mmr2004-Rev

Loading...

Loading...