Section 05 2–TEC ENGINE MANAGEMENT

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

3

A32C9OA

12

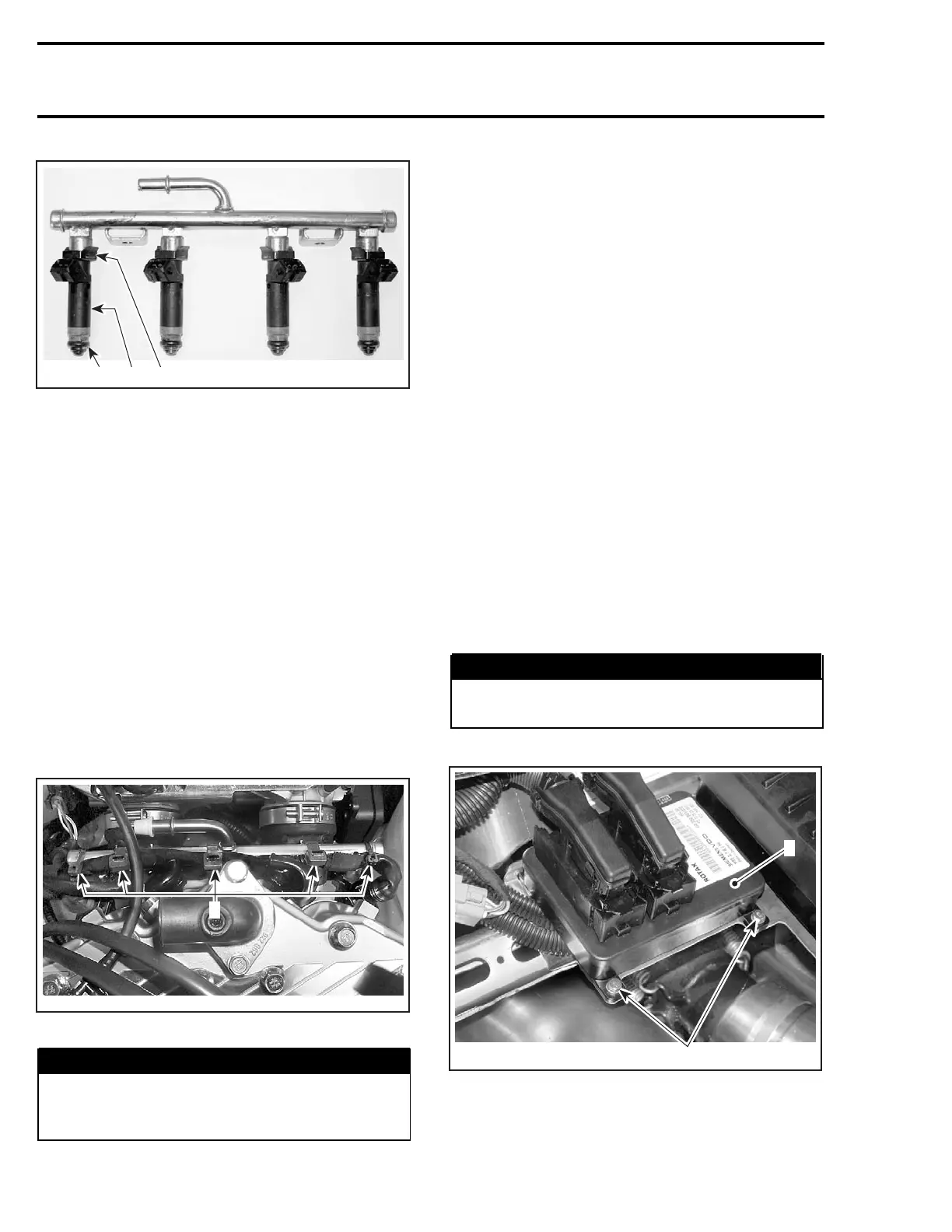

FUEL RAIL ASS’Y

1. Fuel injector

2. Injector clip

3. O-ring

Then remove the injector clip. Now the fuel injec-

tor can be easily pulled out of the fuel rail.

Installation

For the installation, reverse the removal proce-

dure. Pay attention to the following details.

Insert injectors with your hand. Do not use any

tool. Ensure clip and injector are properly in-

stalled.

Replace O-rings with new ones.

NOTE: A thin film of engine oil should be applied

to O-rings to ease insertion in rail.

Torque rail retaining nuts to 10 N•m(89lbf•in).

Attach injector wires with locking tie as shown in

following photo.

A32CCSA

1

1. Locking ties

WARNING

Perform a fuel pressure test and ensure that

there is no leak. Refer to FUEL PUMP above.

Run engine and check for leaks.

ELECTRONIC MANAGEMENT

ECM REPLACEMENT

General

Prior to replacing a suspected ECM, ensure that all

the recommendations in the general introduction

of this section have been followed.

IMPORTANT: When the ECM is replaced, the

tether cord cap(s) and the Closed Throttle must

be reprogrammed/reset. Refer to their specific

section for adjustment.

To allow transferring the previous recorded infor-

mation from the old ECM to the new one, use the

vehicle communication kit (VCK) with the B.U.D.S.

software. Use Replace ECM in the ECM menu.

Follow instructions provided by the help system.

NOTE: If the old ECM can still communicate, it

must be read inside B.U.D.S. prior to removing it

from the vehicle to carry vehicle information and

history to the new ECM.

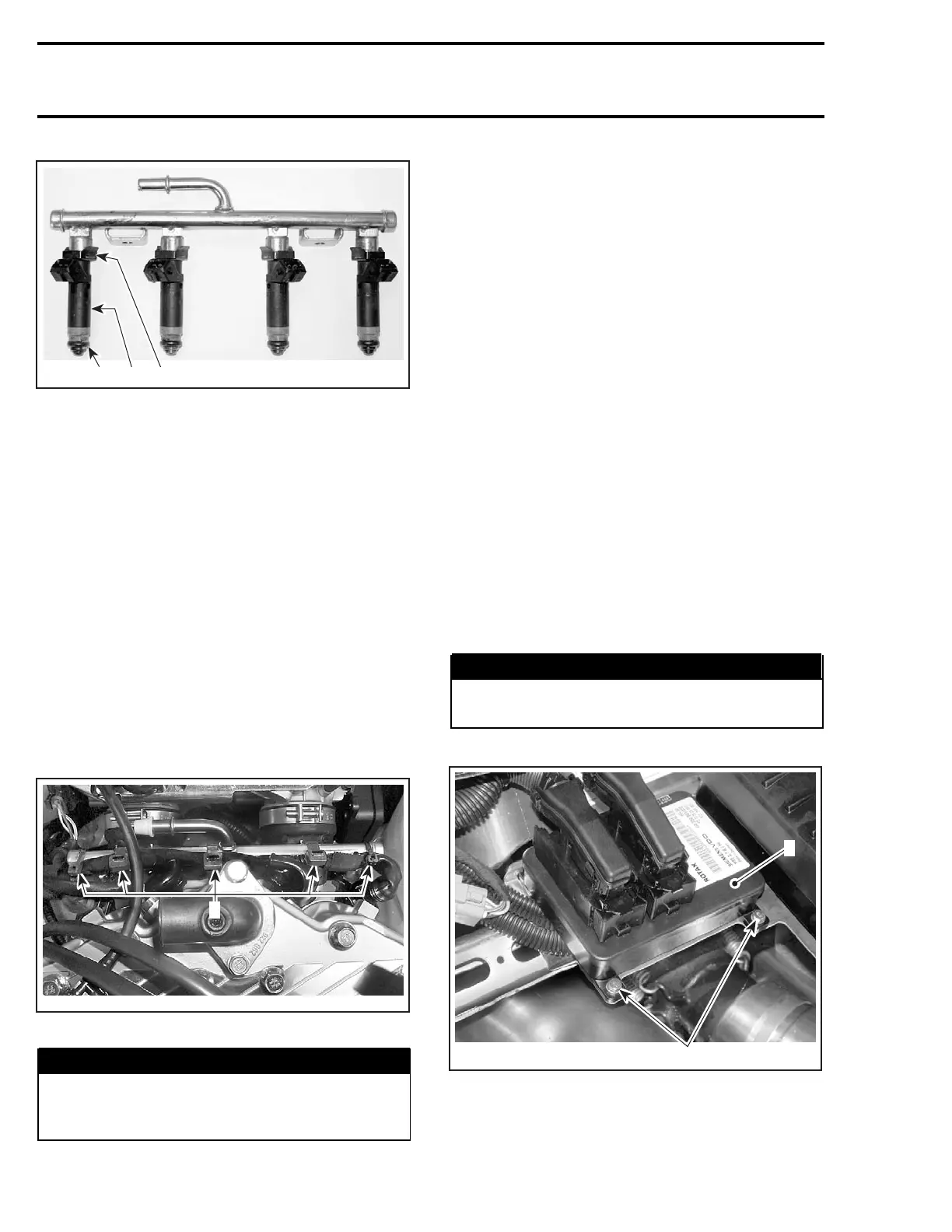

ECM Replacement

Disconnect battery cables.

WARNING

Battery BLACK (-) cable must always be dis-

connected first and connected last.

Disconnect both connectors from ECM.

A33I0HA

1

2

1. ECM

2. Retaining screws

188 mmr2004-Rev

Loading...

Loading...