Section 06 TRANSMISSION

Subsection 02 (DRIVE PULLEY)

Remove 3 Allen screws retaining spring cover

then unscrew compressor.

CLEANING

5,6, Fixed and Sliding Halves

Clean pulley halves and shaft with fine steel wool

and dry cloth.

5,29, Fixed Half/Crankshaft End and

Governor Cup/Fixed Half Post

Parts must be at room temperature before clean-

ing.

Using a paper towel with Pulley flange cleaner

(P/N 413 711 809) , clean crankshaft tapered end

and the taper inside the fixed half of the drive

pulley, crankshaft threads and retaining screw

threads.

Before installation of drive pulley, clean also crank-

shaft threads and retaining screw threads.

WARNING

This procedure must be performed in a well-

ventilated area.

CAUTION: Avoid contact between cleaner and

crankshaft seal because damage may occur.

Remove all hardened oil deposits that have baked

on crankshaft and pulley tapered surfaces with

coarse or medium steel wool and/or sand paper

no. 600.

CAUTION: Do not use any other type of abra-

sive.

Reclean mounting surfaces with paper towel and

cleaning solvent.

Wipe off the mounting surfaces with a clean, dry

paper towel.

CAUTION: Mounting surfaces must be free of

any oil, cleaner or towel residue.

7,20, Bushing

Only use petrol base cleaner when cleaning bush-

ings.

CAUTION: Do not use acetone to clean bush-

ing.

INSPECTION

Drive pulley should be inspected annually.

16,17, Thrust Washer and Roller

Check roller for roundness of external diameter.

Check thrust washer for thickness wear. Replace

as required.

CAUTION: Ensure rollers are in good condition.

Replace as required.

9,12, Fitting Bolt Ass’yand

Flanged Bushing

Check for wear, replace as required.

24,25, O-ring and Slider Shoe

Check if O-rings are cracked, cut or crushed. Re-

place as required.

Check slider shoes for wear. Replace if groove is

not apparent on top.

5,29, Fixed Half and Governor Cup

Inspect splines and free play between both parts.

Maximum free play is 0.5 mm (.020 in) measured

at calibration screw radius. Replace if required.

7,20, Sliding Half and Spring

Cover Bushing

Visually inspect coating. Replace if worn.

Sliding Half Bushing Replacement

NOTE: In case of worn out bushing, it is advisable

to replace whole sliding half ass’yasreplacingjust

the bushing may reduce the drive pulley perfor-

mance.

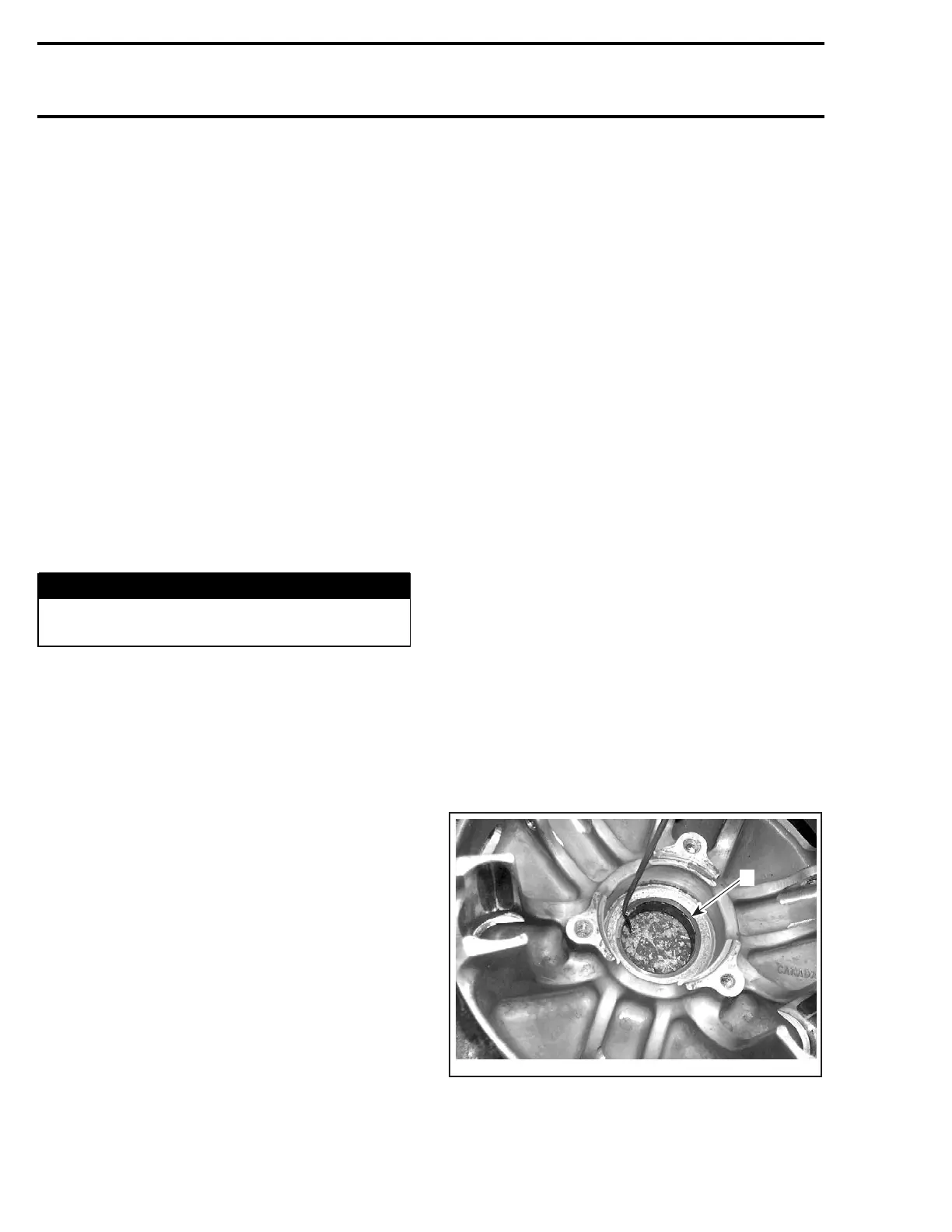

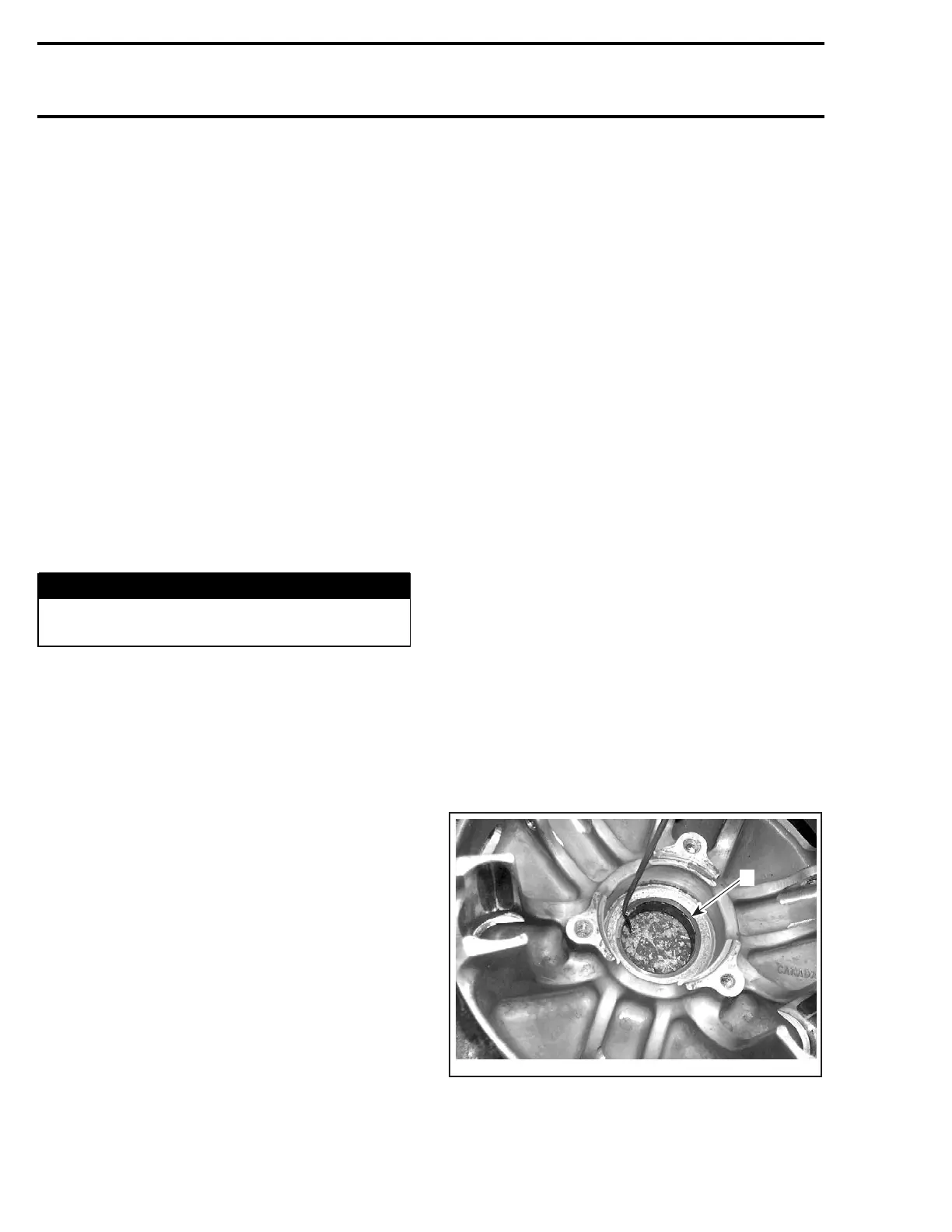

Remove circlip from the sliding half.

A32D2TA

1

1. Circlip

218 mmr2004-Rev

Loading...

Loading...