Section10BODY/FRAME

Subsection 02 (FRAME)

FRAME

FRAME CLEANING

NOTE: For bare aluminum frames use only

aluminum cleaner and follow instructions on con-

tainer. (Dursol cleaner or equivalent).

Clean frame and tunnel with appropriate cleaners

and rinse with high pressure hose.

CAUTION: Never direct high-pressure water jet

towards decals. They will peel off.

Touch up all metal spots where paint has been

scratched off. Spray all bare metal parts of vehicle

with metal protector.

Seat Cleaning

For all models, it is recommend to clean the seat

with a solution of warm soapy water, using a soft

clean cloth.

CAUTION: Avoid use of harsh detergents such

as strong soaps, degreasing solvents, abrasive

cleaners, paint thinners, etc., that may cause

damage to the seat cover.

FRAME WELDING

Aluminum Frame

– No welds should be done on aluminum frame

except if mentioned or required on a Bom-

bardier bulletin.

– Use ER-5356 rods for MIG or TIG welding.

CAUTION: Before performing electrical weld-

ing anywhere on the vehicle, unplug MPEM.

On models equipped with a battery, also un-

plug the negative cable. This will protect the

electronic box and battery against damage

caused by flowing current when welding.

A32E0WB

TYPICAL — MPEM UNPLUGGED

CAUTION: If welding is to be done near plastic

material, it is recommended to either remove

the part from the area or to protect it with alu-

minum foil to prevent damage.

FRAME COMPONENT

REPLACEMENT

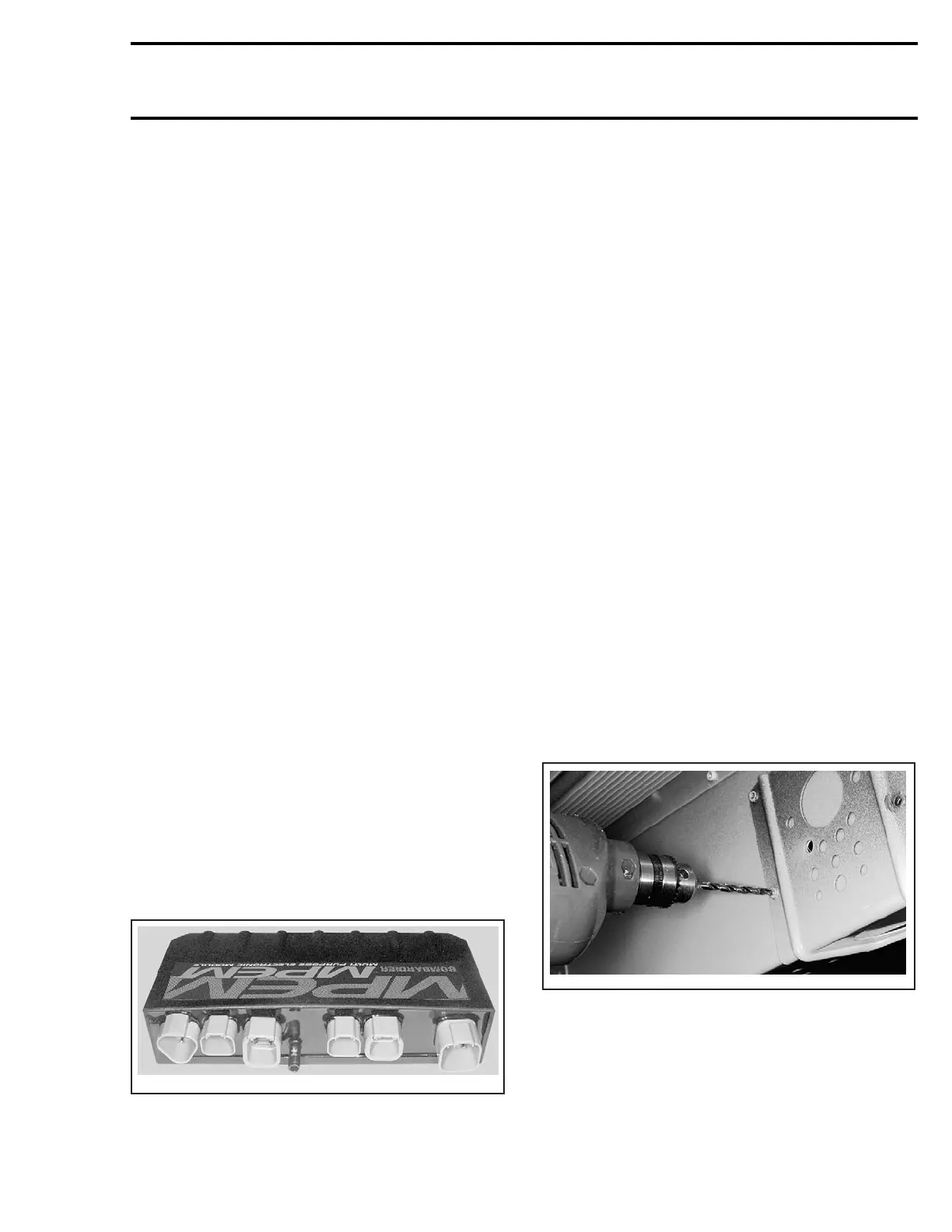

Drilling Procedure

When drilling self-piercing rivets, use Superta-

nium

TM

drill bit (P/N 529 031 800), available in a 5

mm (3/16 in) size and shipped in packs of 2.

For proper drilling instructions and to prevent pre-

mature wear, follow the procedure below.

Always use a variable speed electric drill.

Partially drill rivet end — not the rivet head.

Maintain a slow to medium speed at all times

when drilling. The proper speed is attained when

a constant chip is ejected.

NOTE: To increase bit life, use Bombardier syn-

thetic chaincase oil (P/N 413 803 300) as a cutting

oil.

CAUTION: High speed drilling will cause exces-

sive heat which may destroy the cutting edge

of the bit; therefore, avoid using pneumatic

drills.

A03H2FA

TYPICAL

Cut rivet using a chisel.

Remove riveted part.

Drive out remaining rivet head using a punch.

mmr2004-Rev 347

Loading...

Loading...